Automatic gluing and plate arranging machine

A slatting machine and gluing technology, which is used in the joining of wooden veneers, adhesive application devices, wood processing appliances, etc. The effect of fast, improved board arrangement speed, and avoidance of card board downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

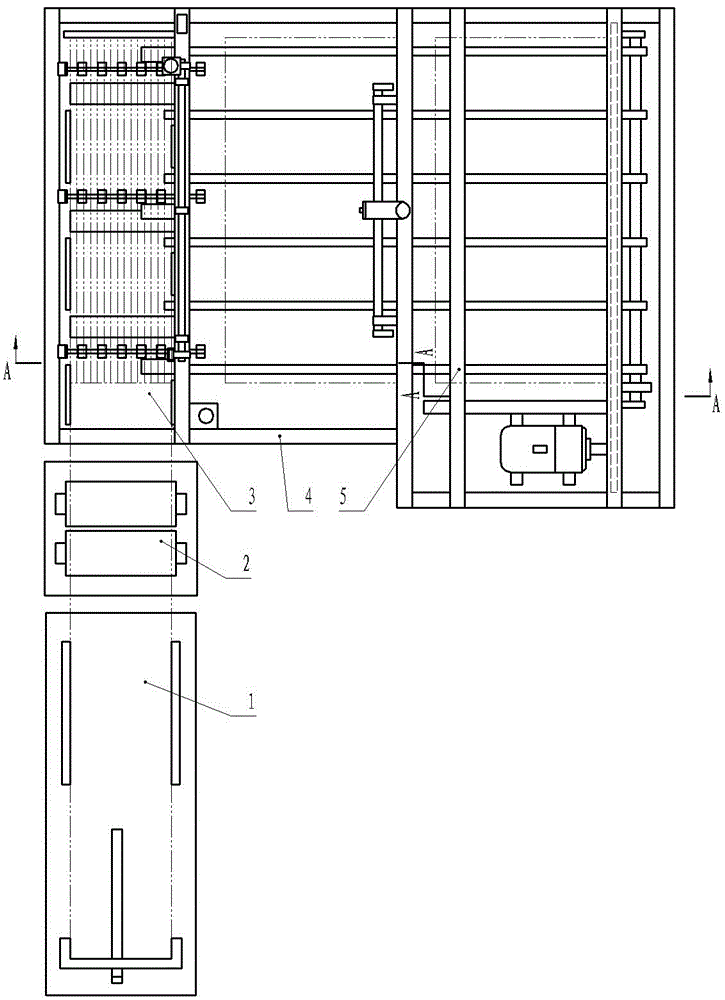

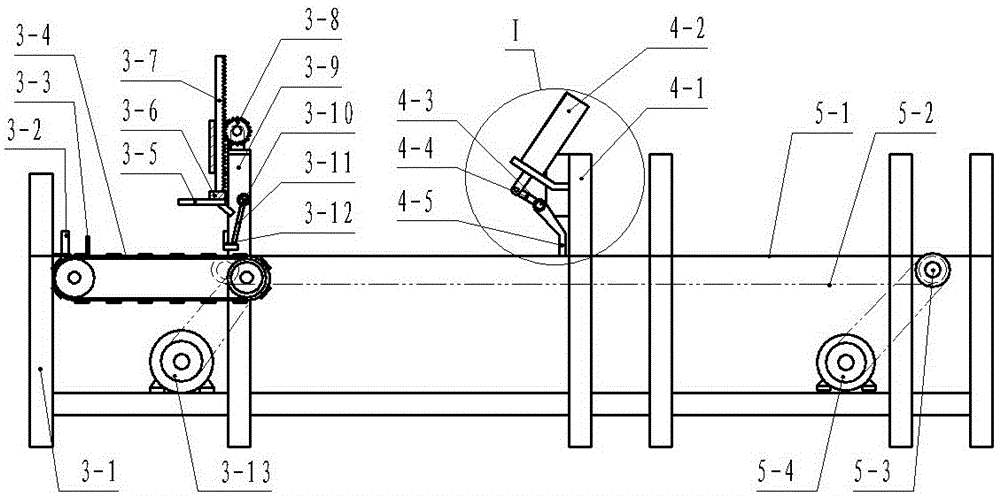

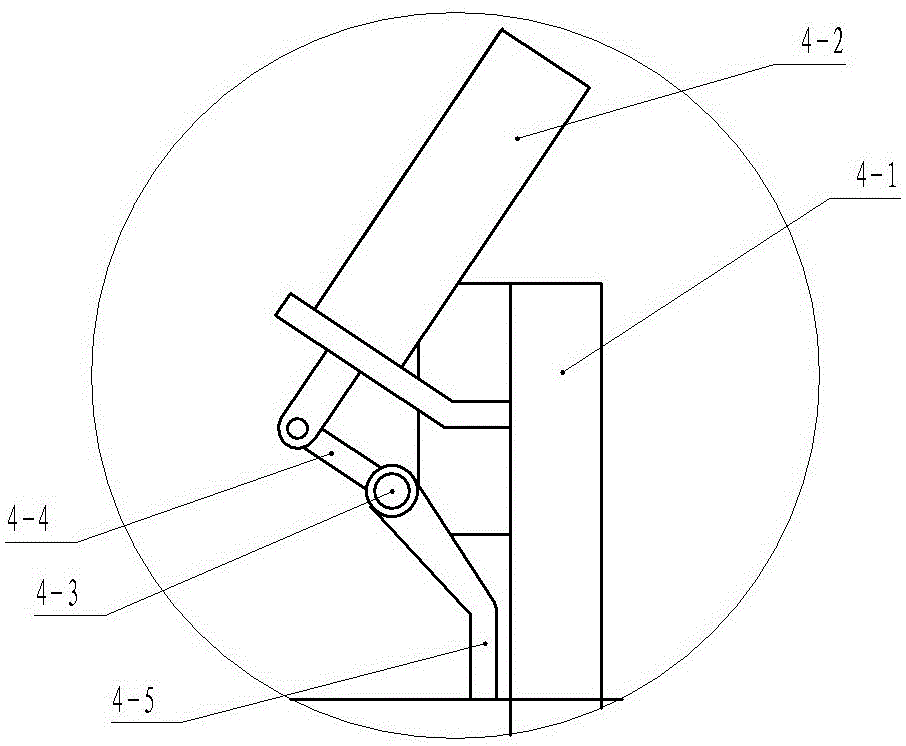

[0025] Such as figure 1 , figure 2 The shown automatic gluing board arrangement machine includes a slat pusher 3 and a slatter pusher 5, and the slat pusher 3 includes a slat support frame with an inlet 3-21 and an outlet 3-22 3-1, the slat supporting frame 3-1 is equipped with the glue applicator 2 and the feeding device 1 in turn on the feeding side, and the slat supporting frame 3-1 is equipped with intervals driven by the first motor 3-17 Three conveying rollers 3-16, three conveying rollers 3-16 are connected with the first motor 3-17 by chain drive; Three conveying chains 3-4 arranged at intervals are housed on the slat supporting frame 3-1, conveying chain The walking direction of 3-4 is set parallel to the axis of the conveying roller 3-16, and the conveying chain 3-4 includes a chain that surrounds the driving sprocket and the driven sprocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com