Modified planar rolling method and device

A rolling and flat technology, applied in the field of rolling processing, can solve the problems of low machining accuracy, easy thermal deformation of the machined surface, poor uniformity, etc., and achieve the effects of high machining accuracy, low cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

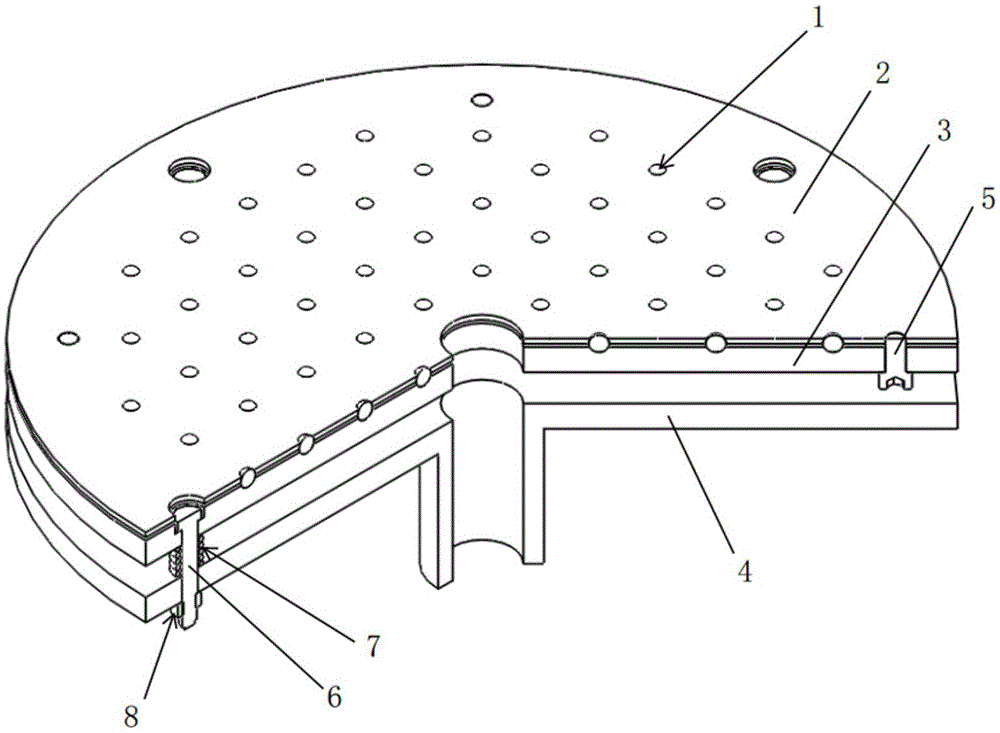

[0042] The implementation method of rolling grinding is as follows:

[0043] refer to Figure 4 , the workpiece 11 is attached below the planetary wheel 10, and the workpiece faces the balls 1 distributed on the grinding upper disc 3. The relative position arrangement of center wheel 12, planetary wheel 10 and internal gear 9 on the rolling grinding disc, as Figure 5 shown.

[0044] refer to Figure 4 , apply a load to the planetary wheel 10, and the load is transmitted to the workpiece 11, the ball 1 and the upper grinding disc 3 in turn. The load can be applied through the cylinder or the screw nut, and the loading method is not required here.

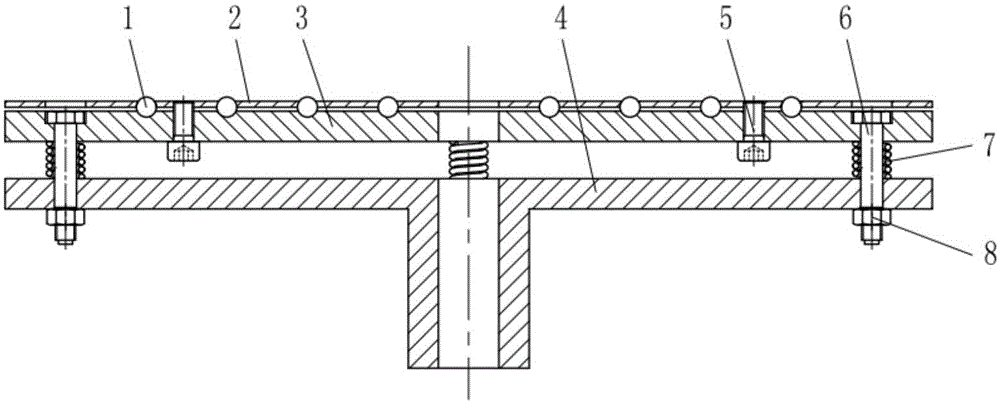

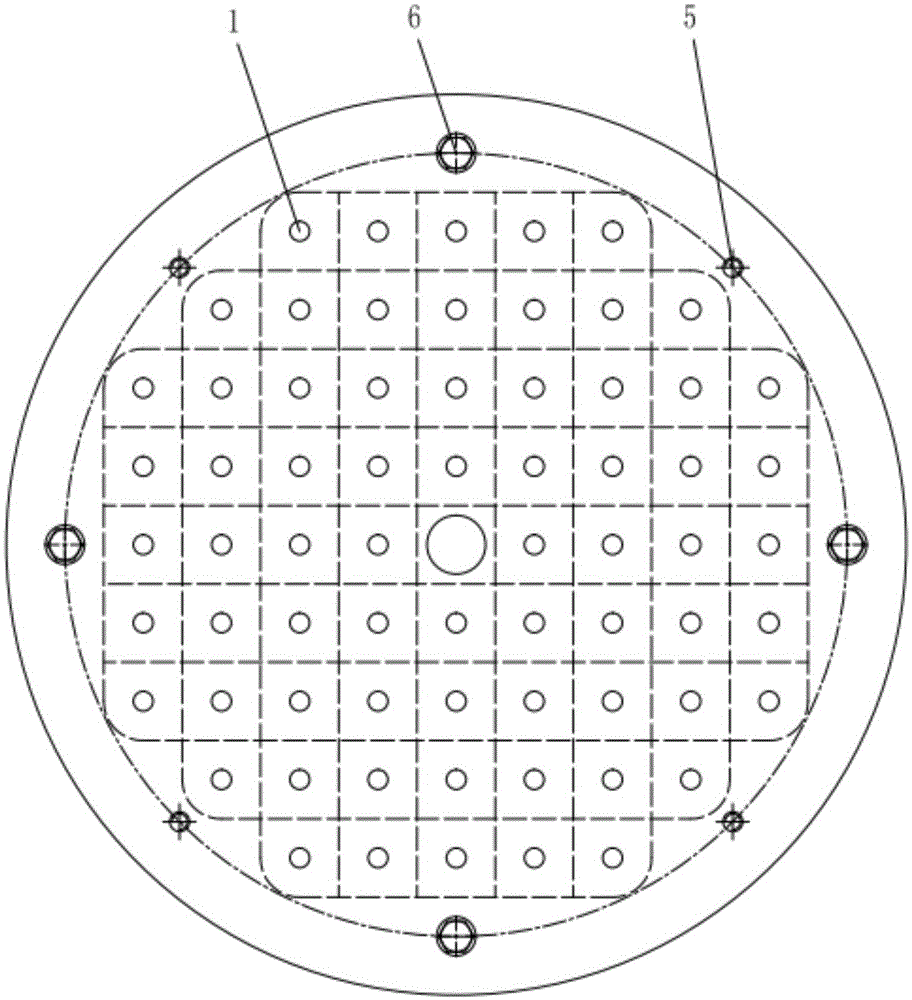

[0045] refer to figure 1 with image 3 , The grinding upper disc 3 has a tendency to move downward under the action of the rolling load. When the load exceeds the pre-tightening force of the spring 7, the grinding upper plate 3 will continue downward along the screw rod, and the pre-tightening force will gradually increase un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com