A beneficiation process of rock-type primary ilmenite

A technology of ilmenite and rock type, which is applied in the mineral processing field of rock type primary ilmenite to achieve the effect of comprehensive utilization of resources and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

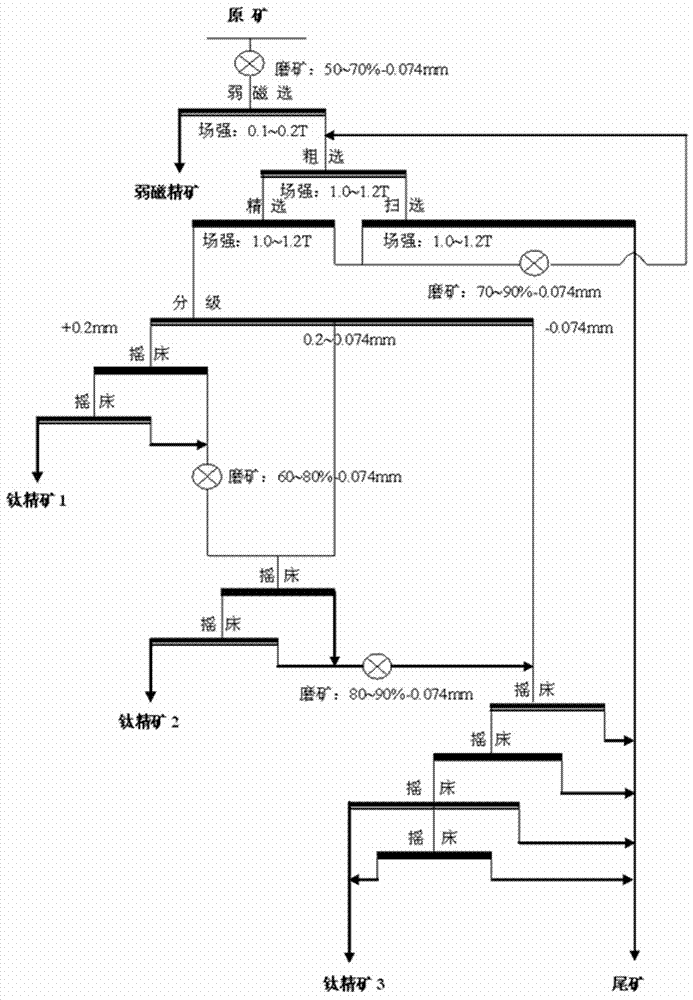

Method used

Image

Examples

Embodiment 1

[0056] Composition of rock-type primary ilmenite ore processed: TiO 2 5.52%, Fe 12.36%, CaO 9.10%, MgO5.33%, Al 2 o 3 13.69%, SiO 2 45.87%.

[0057] Above-mentioned raw ore is passed through following processing steps:

[0058] (1) Crushing all the raw ore to -10mm;

[0059] (2) Grind the crushed ore in a closed circuit, and the fineness of the grinding product -0.074mm accounts for 50%;

[0060] (3) The grinding products are magnetically separated by a weak magnetic separator with a magnetic field strength of 0.2T. Weak magnetic separation tailings are obtained after removing ferromagnetic minerals by weak magnetic separation;

[0061] (4) The tailings of the weak magnetic separation are magnetically separated by a high-gradient strong magnetic separator. The strong magnetic separation process is one roughing, one sweeping, and one beneficiation. The background magnetic field strength is 1.0T. After regrinding, the ore returns to roughing, and the regrind product fine...

Embodiment 2

[0069] Composition of rock-type primary ilmenite ore processed: TiO 2 4.16%, Fe 10.41%, CaO11.20%, MgO6.71%, Al 2 o 3 11.77%, SiO 2 46.92%.

[0070] Above-mentioned raw ore is passed through following processing steps:

[0071] (1) Crushing all the raw ore to -15mm;

[0072] (2) Grind the crushed ore in a closed circuit, and the fineness of the grinding product is -0.074mm, accounting for 70%;

[0073] (3) The grinding products are magnetically separated by a weak magnetic separator with a magnetic field strength of 0.2T. Weak magnetic separation tailings are obtained after removing ferromagnetic minerals by weak magnetic separation;

[0074] (4) The tailings of the weak magnetic separation are magnetically separated by a high-gradient strong magnetic separator. The strong magnetic separation process is one roughing, one sweeping, and one beneficiation. The background magnetic field strength is 1.2T. After regrinding, the ore returns to roughing, and the regrind produc...

Embodiment 3

[0082] Composition of rock-type primary ilmenite ore processed: TiO 2 6.94%, Fe 15.47%, CaO8.46%, MgO7.90%, Al 2 o 3 19.54%, SiO 2 36.37%.

[0083] Above-mentioned raw ore is passed through following processing steps:

[0084] (1) Crushing all the raw ore to -10mm;

[0085] (2) The crushed ore is ground in a closed circuit, and the fineness of the grinding product is -0.074mm, accounting for 60%;

[0086] (3) The grinding products are magnetically separated by a weak magnetic separator with a magnetic field strength of 0.15T. Weak magnetic separation tailings are obtained after removing ferromagnetic minerals by weak magnetic separation;

[0087] (4) The tailings of the weak magnetic separation are magnetically separated by a high-gradient strong magnetic separator. The strong magnetic separation process is one roughing, one sweeping, and one beneficiation. The background magnetic field strength is 1.0T. After regrinding, the ore returns to roughing, and the regrind pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com