Yogurt stabilizer preparation method and high-quality yogurt

A high-quality, stabilizer technology, applied in the fields of food chemistry, food microorganisms, and food processing, can solve problems such as damp-heat phosphorylation barriers, achieve uniform texture, high viscosity, and speed up fermentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Example 1: A method for preparing a high-quality stabilizer for yogurt, characterized in that it is carried out according to the following steps:

[0072] (1) Protein solution preparation: prepare a solution with a protein concentration of 9.5-10% with distilled water and whey protein isolate (WPI), adjust the pH value = 7.5, and keep it at 60°C for 30 minutes;

[0073] (2) Addition of sodium tripolyphosphate (STPP): add 0.09% of sodium tripolyphosphate in terms of mass percentage to the above solution, stir magnetically for 1.5h at room temperature to obtain a mixed solution, and adjust the pH of the mixed solution to 8.2;

[0074] (3) Thermal polymerization: preheat at 65°C for 3-5 minutes, then polymerize at 75°C for 12 minutes, and finally continue thermal polymerization at 85°C for 20 minutes, then immediately cool to room temperature, and obtain powder by vacuum freeze drying or spray drying.

Embodiment 2

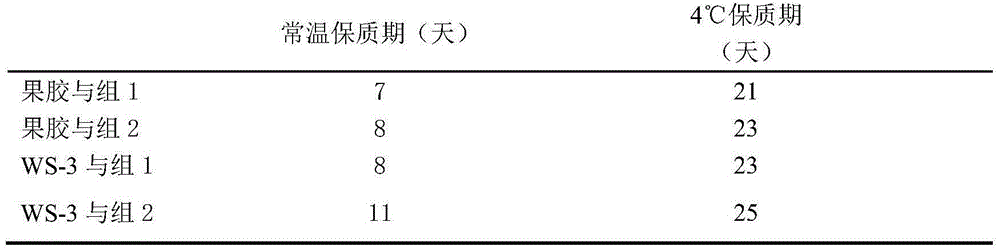

[0075] Embodiment 2: A method for preparing high-quality yogurt, characterized in that it is prepared according to the following steps;

[0076] Fresh milk→sterilization (90°C, 5min)→cooling (to 43°C)→inoculate the starter with 2% of the inoculum amount, and then add the stabilizer according to claim 3 or embodiment 1, and the amount is calculated by mass percentage 0.5-0.7% of fresh milk → two-stage fermentation: first incubate at 40-41°C for 4 hours, then at 35-37°C for 4 hours → 4°C storage → post-ripening for 12 hours or 24 hours; the starter is preferably Bulgaria Lactobacillus, Bifidobacterium, Lactobacillus plantarum and Streptococcus thermophilus are combined, and based on the number of viable bacteria, Lactobacillus bulgaricus, Bifidobacterium, Lactobacillus plantarum, and Streptococcus thermophilus=1:2:2 : Mix in the ratio of 2. The yogurt still has 1.0×10 after being stored at 4℃ for 21 days 9 CFU / mL of Bifidobacterium.

Embodiment 3

[0078] A culture medium, characterized in that the culture medium is a special culture medium for the starter mixed bacteria of the present invention, which is prepared by the following components and dosages: 75g skimmed milk powder, 20g lactose, 5g inulin, 50g glucose Syrup, 4g xylo-oligosaccharides, 4g soy peptone, 4g tryptone, 4g tomato juice, 1mg uracil, 1mg proline and cysteine, 0.005mg vitamin C, 1mg calcium gluconate and calcium carbonate, 1g Tomato juice, 0.5mg riboflavin, 0.005mg manganese sulfate, 0.005mg ferric chloride, 0.01g formic acid, add distilled water and dilute to 1000mL; the ratio of proline and cysteine is 1:2, glucose The ratio of calcium acid to calcium carbonate is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com