A Torque Adjustable Handwheel Mechanism

An adjustable, handwheel technology, applied in the connection/disconnection of connection devices, electrical components, coupling devices, etc., can solve the problems of inability to adjust, reduce equipment use efficiency, waste of resources, etc., to achieve convenient and simple installation and improve maintenance. , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

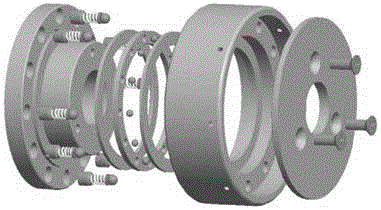

[0016] Below in conjunction with accompanying drawing, structure of the present invention and installation are described as follows:

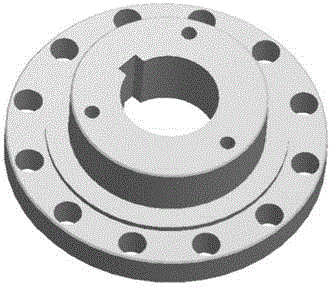

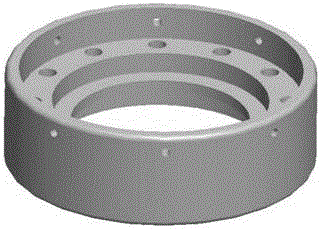

[0017] Such as figure 1 As shown, the small steel ball 5 is installed in the small hole of the steel ball holding piece 3, and the lower steel ball supporting piece 4 and the upper steel ball supporting piece 2 sandwich the small steel ball 5 and the steel ball holding piece 3, forming a similar plane The steel ball-steel ball supporting piece-steel ball holding piece structure of the thrust bearing. The lower steel ball support piece 4 is in contact with the outer circular step of the handwheel body 8, and the upper steel ball support piece 2 is in contact with the inner hole step of the handwheel rim, which can realize the downward axial limit of the handwheel rim 1 and realize the handwheel rim at the same time. 1 relative to the free rotation of the handwheel body 8.

[0018] The top of the handwheel body 8 is provided with 3 or more even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com