Terminals for circuit board connection

A circuit substrate and terminal technology, which is applied in the direction of circuits, connections, fixed connections, etc., can solve the problems of increased projected area of circuit substrates, high-density installation obstacles of circuit substrates, and the formation of non-plane adsorption areas near the center of gravity, etc., to achieve high-density installation , the effect of high connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

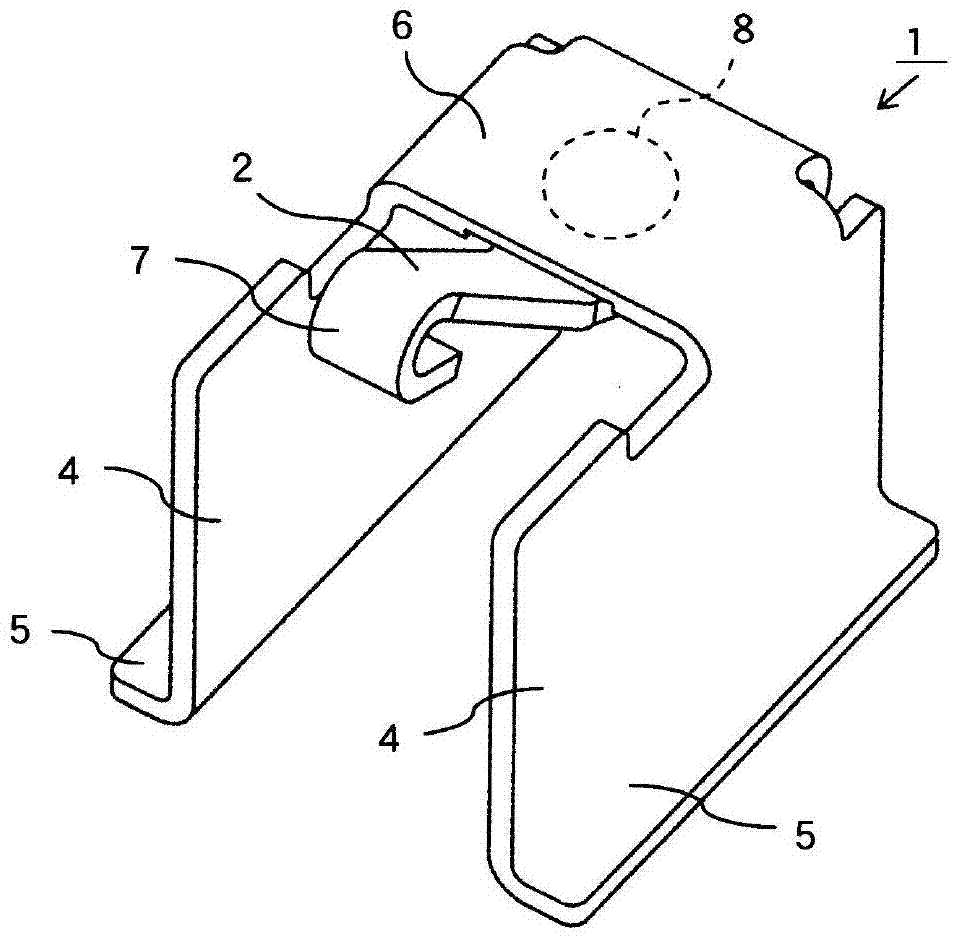

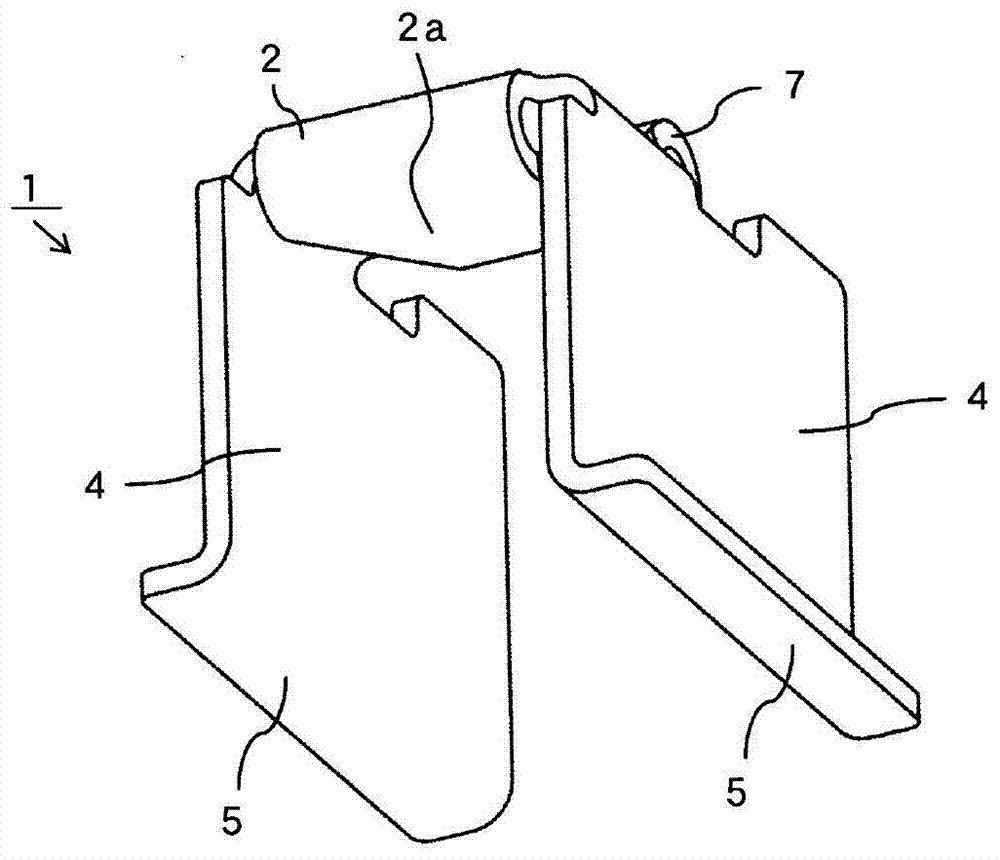

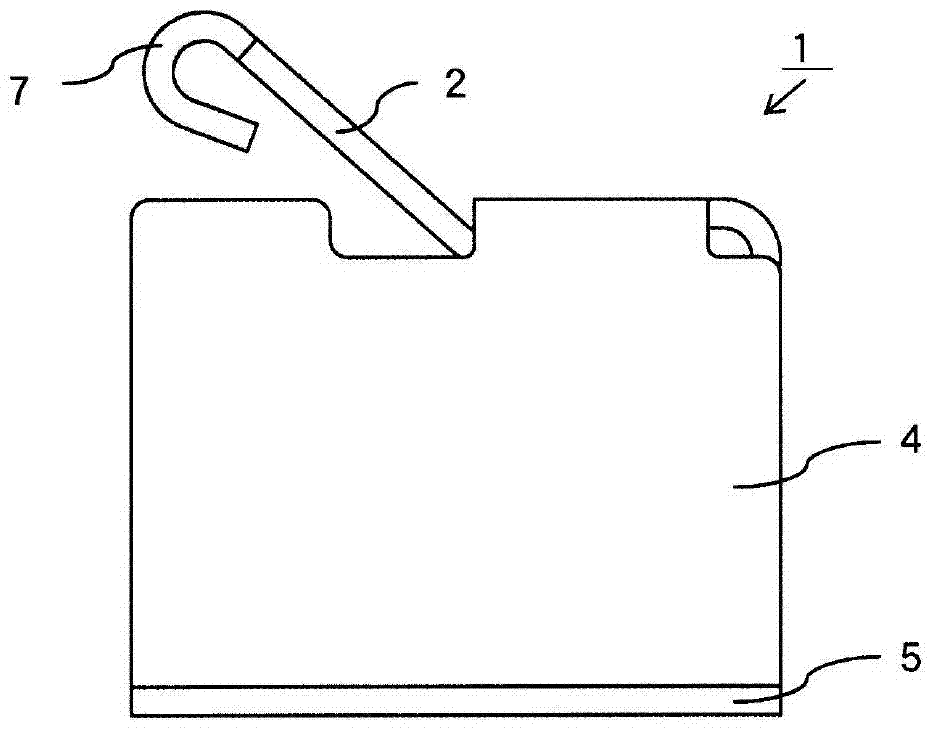

[0071] Below, use Figure 1 ~ Figure 5 as well as Figure 8 (a) The circuit board connection terminal 1 according to an embodiment of the present invention will be described. The circuit board connection terminal 1 is as Figure 5 As shown, the shielding case 10 of the electronic device is electrically connected to the unillustrated grounding pattern of the printed wiring board 11, and the terminal is mounted on the printed wiring board 11 for the purpose of grounding. Therefore, hereinafter referred to as It is the ground terminal 1. Also, in the following description, image 3 The left side is the front, the right side is the rear, and the vertical direction is the same as the vertical direction. Explain the position of each part.

[0072] Terminal 1 for circuit board connection Figure 1 ~ Figure 4 As shown, it is integrally formed of a conductive metal plate with elasticity such as phosphor bronze, titanium copper, etc.: a pair of rectangular plate-shaped legs 4, 4 standing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com