Support body and method for inspecting magnetic component therewith

A technology of magnetic components and support bodies, applied in the direction of support head, head hydrodynamic spacing, configuration/installation of recording head, etc., can solve problems such as long working time, high-efficiency manufacturing restrictions, complicated fixing operations, etc., to achieve Maintain an easy, less misplaced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

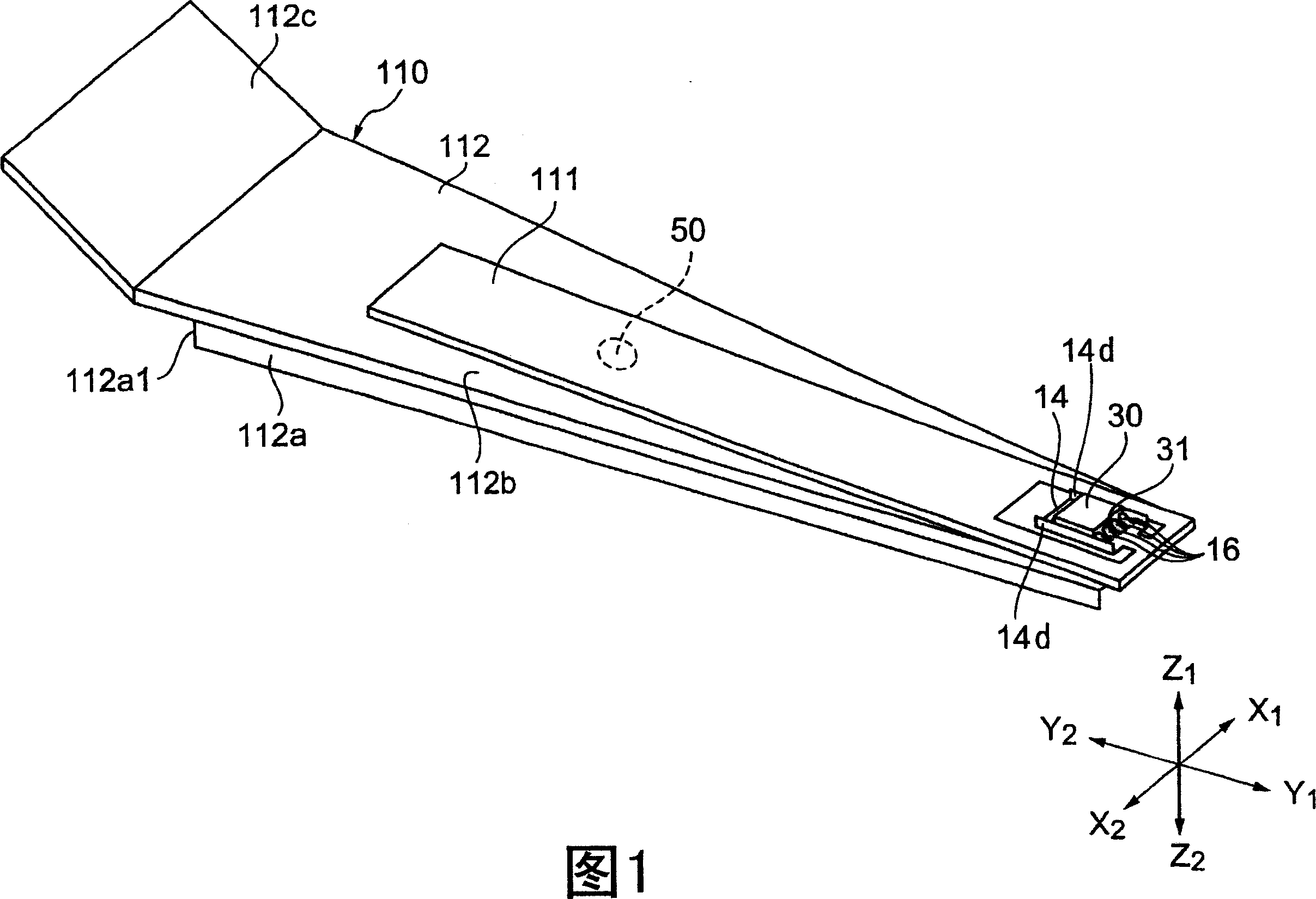

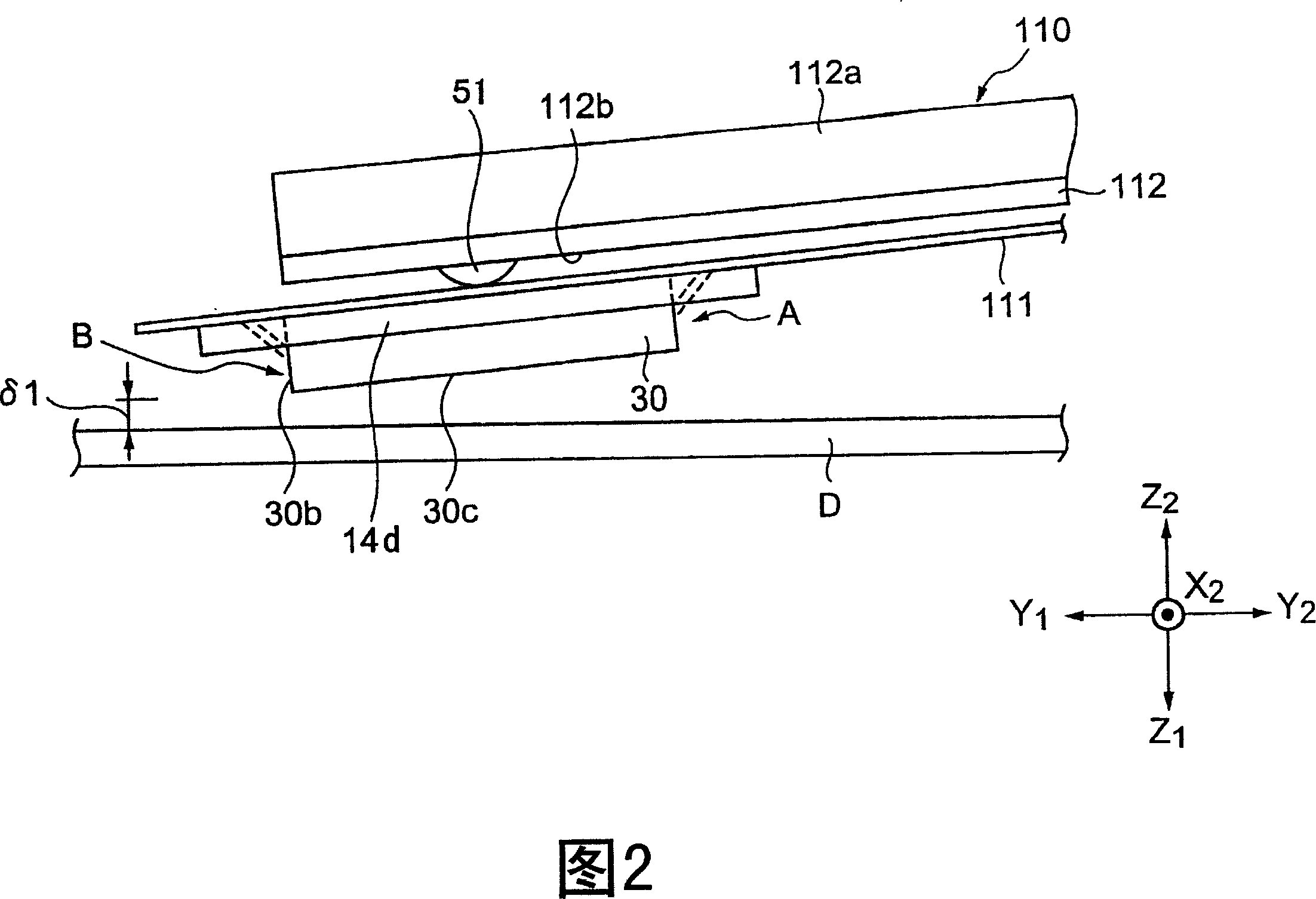

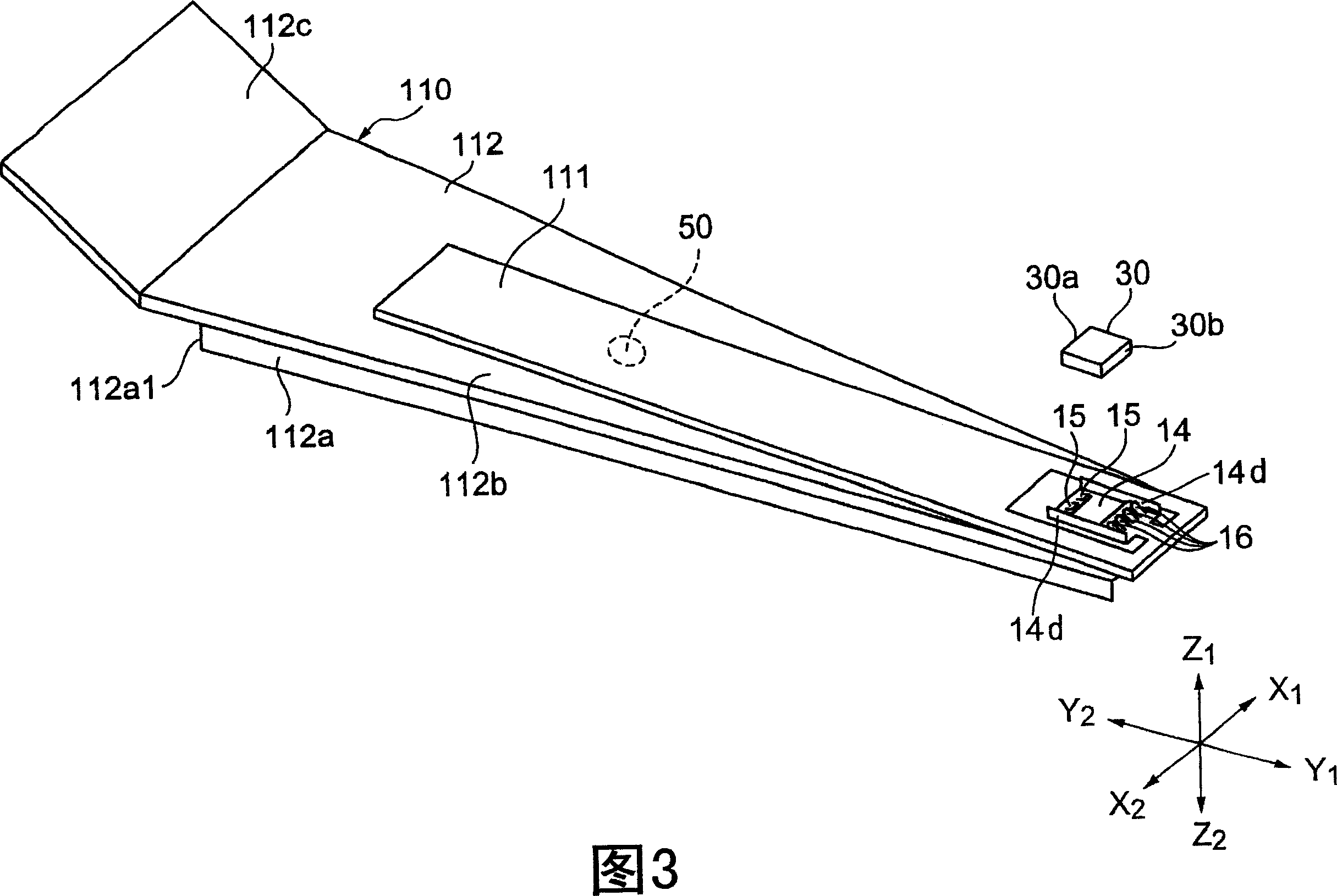

[0054] Fig. 1 is a partial perspective view showing a support body and a sliding body supported on the support body according to an embodiment of the present invention on the side opposite to the recording medium, and Fig. 2 is a diagram showing the side opposite to the recording medium. A partial side view of the supporting body and the sliding body shown in FIG. 1 is shown together with the recording medium in the state of the lower side, and FIG. 3 is an exploded perspective view showing the surface of the supporting body and the sliding body shown in FIG. 1 facing the recording medium. , FIG. 4 is a perspective view of the sliding body held on the support shown in FIG. 1 . In addition, in each figure, the Z1 direction shown is the surface facing a recording medium.

[0055] As shown in FIG. 1 , the support body 110 is composed of a load beam 112 as a first support portion and a flexible plate 111 as a second support portion fixed to the load beam 112 . The flexible plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com