Oblique block elevating mechanism for wafer test

A technology of wafer testing and lifting mechanism, which is applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc. It can solve problems such as poor jacking stability, high manufacturing cost, and small jacking force, and achieve The effect of large jacking force, low manufacturing cost and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

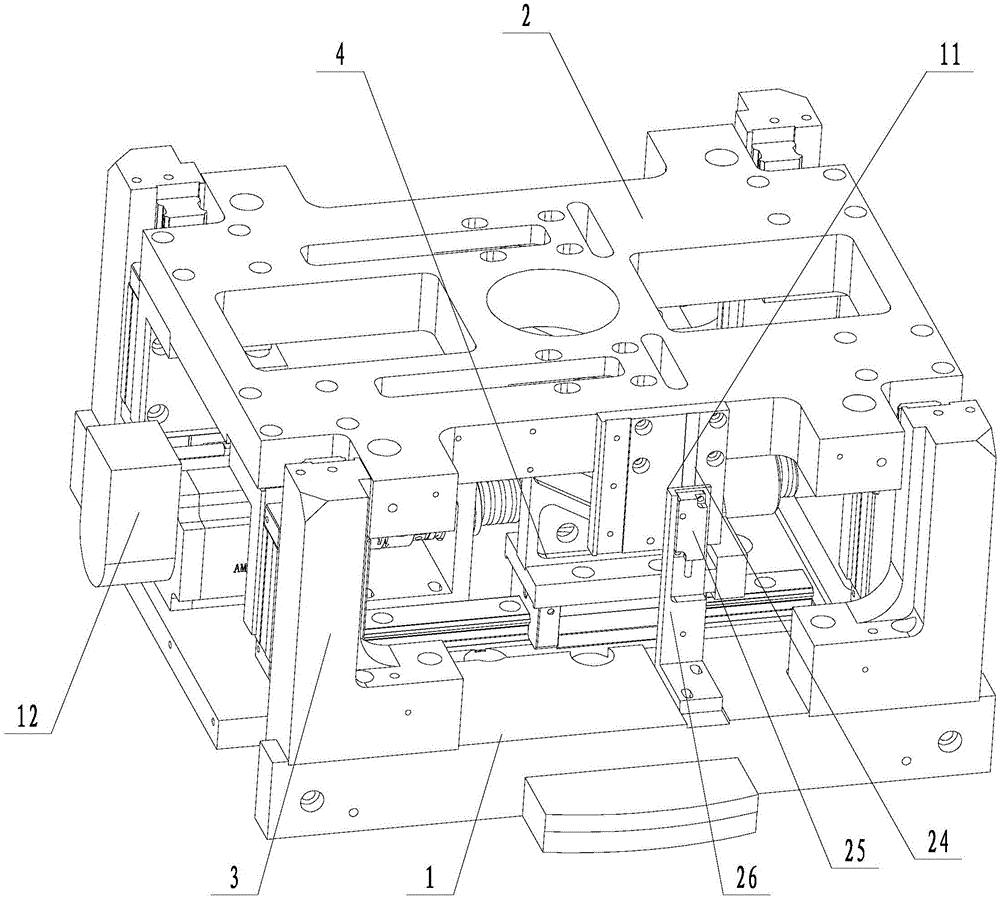

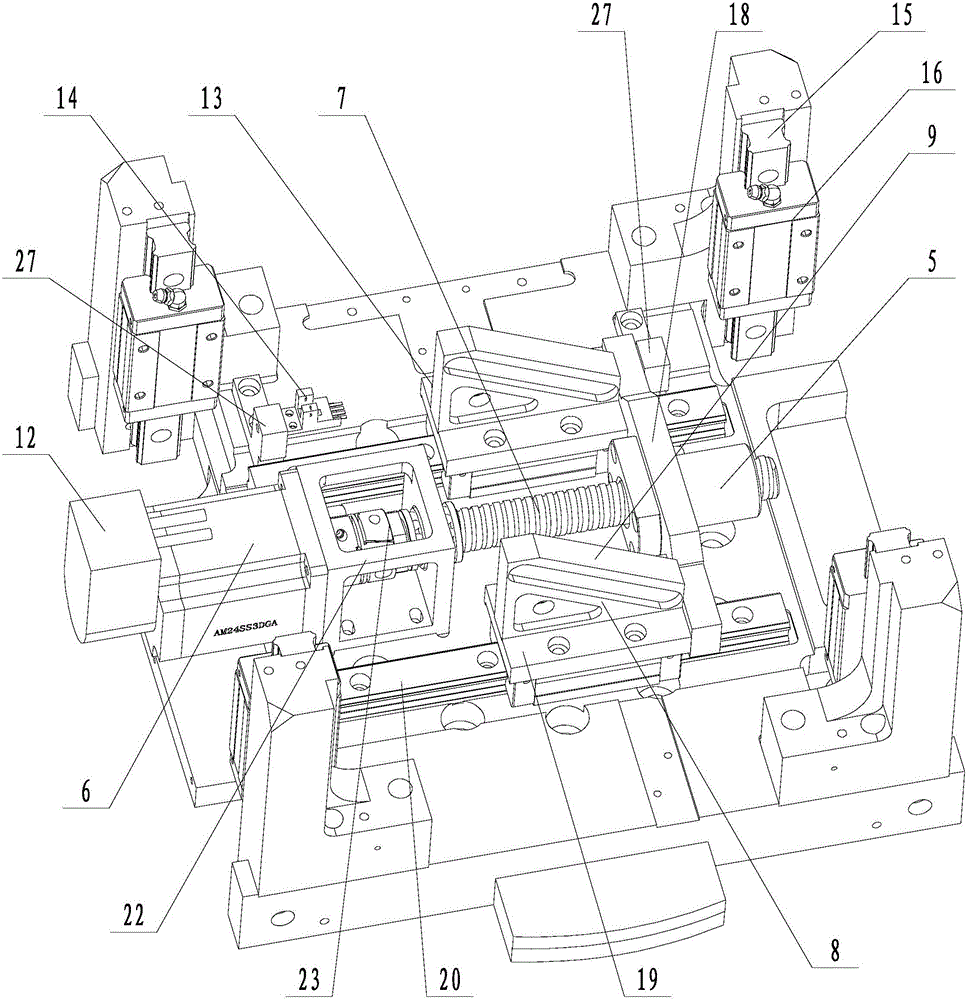

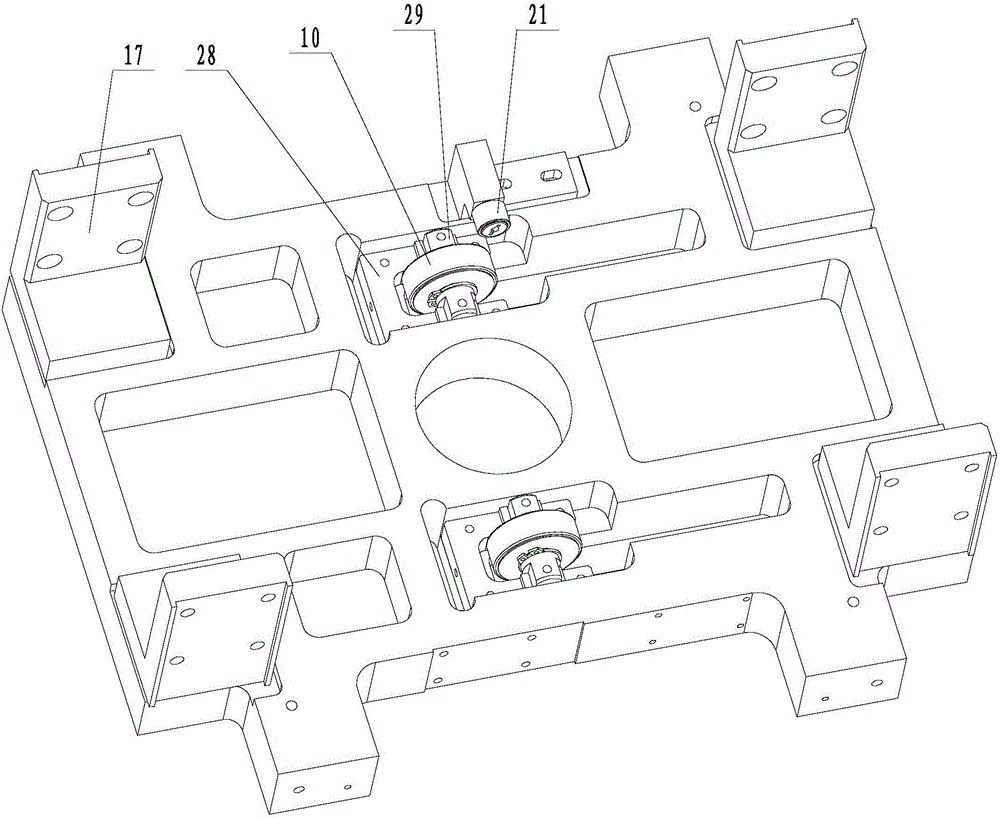

[0023] Embodiment: a kind of inclined block lifting mechanism of wafer test (see attached figure 1 , attached figure 2 , attached image 3 ), including a base 1 and a supporting plate 2, the base and the supporting plate are in a rectangular structure, the base is fixedly connected with four lifting slide rail seats 3, and the lifting slide rail seat is vertical to the base. The four lifting slide rail seats are respectively arranged at four corner positions of the base. Supporting plate can be lifted and connected on the lifting slide rail seat, and the lifting slide rail seat is all provided with linear guide rail 15, and slide block 16 is slidably connected on the linear guide rail, and slide block is all fixedly connected with supporting plate lower surface. The four corner positions of the supporting plate are all fixedly connected with L-shaped connecting blocks 17, and the lifting slide rail seat and the connecting blocks are correspondingly provided with four, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com