Chip BGA packaging reinforcing method

A chip and reinforcement glue technology, applied in the field of chip BGA packaging reinforcement, can solve the problems of damage to peripheral components, different heating temperatures, and single glue removal method, and achieve the effect of increasing internal bonding force, improving strength, and ensuring reinforcement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0041] Synthesis Example 1 Synthesis of Monofunctional Acrylic Ester Monomer

[0042] Add 12mL of hydroxyacrylic acid, 5ml of dimethylsilanediol, 100ml of absolute ethanol and 1g of sulfamic acid into the three-necked flask, reflux and stir for 3 hours, cool, and filter to obtain the liquid; then add 2ml of 85% phosphoric acid, 50ml of Dehydrated alcohol, reflux, stirring reaction for 10 hours, through silica gel column chromatography, developing agent is dichloromethane, obtain light yellow liquid, be monofunctional acrylate monomer, 1 HNMR (400MHz, CDCl 3 )δ5.58(s, -C=CH 2 ,1H),6.11(s, -C=CH 2 ,1H),1.85(s, CH 3 ,3H); 31 P-NMR (ppm): 1.11.

Embodiment 1

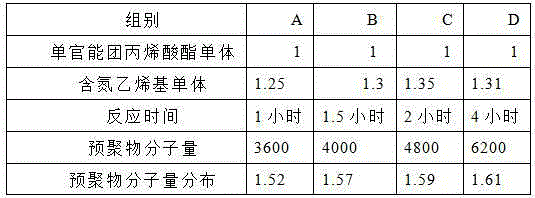

[0043] Example 1: Preparation of thermosetting acrylic resin prepolymer

[0044] According to the composition molar ratio and reaction parameters in Table 1, first add benzoyl peroxide (3% of the mass of acrylic acid monomer) and dioxane into the reactor, heat to reflux, and then add monofunctional acrylate monomer , nitrogen-containing vinyl monomer, reflux reaction, then lower the temperature to 60 ° C, remove the solvent in vacuum, and finally add alcohol amine (5% of the mass of the acrylic acid monomer), and obtain a thermosetting acrylic resin prepolymer by column chromatography, which is a water-soluble Properties, molecular weight and molecular weight distribution are shown in Table 1.

[0045] Table 1 Acrylic acid monomer composition and product molecular weight

[0046]

[0047] The structural formulas of monofunctional acrylate monomer and nitrogen-containing vinyl monomer are respectively: , .

Embodiment 2

[0048] Embodiment two: the preparation of reinforcing glue

[0049] According to the mass parts in Table 2, pour the silica sol into container A, and keep the temperature at 25°C; put the thermosetting acrylic resin prepolymer into container B, stir at 80°C for 1h, then add the thermosetting acrylic resin prepolymer In the silica sol, stir for 0.5h; then add the water-based polyurethane compound into container A, and continue stirring for 2h; finally, add paraffin wax into container A, stir for 0.5h to obtain a BGA packaging reinforcement that can be cured at room temperature; out of the container for packaging.

[0050] Table 2 Reinforcing glue composition (mass parts)

[0051] group Silica sol Thermosetting Acrylic Prepolymers Water-Based Polyurethane Compounds paraffin 1 50 30(A) 1 1 2 55 40(B) 1 3 3 56 35(C) 2 4 4 60 40(A) 3 5 5 58 38(B) 2 2 6 52 40(D) 2 3

[0052] Among them, 30(A) represents 30 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com