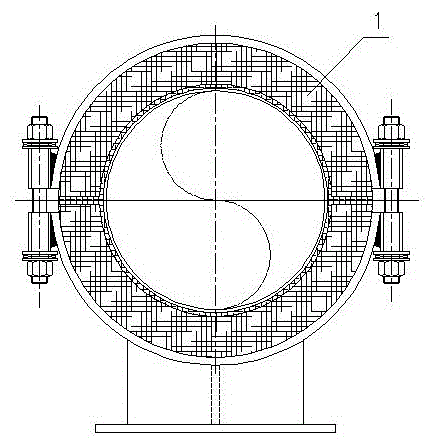

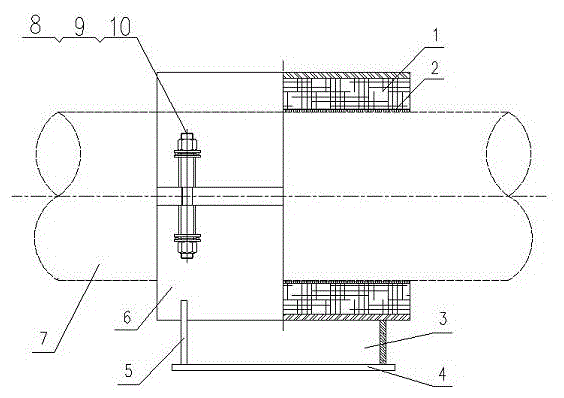

Heat-insulation block for a shock-resistance and heat-insulation pipe bracket and a manufacturing method

A manufacturing method and heat insulation block technology, which is applied in the direction of heat insulation protection pipelines, pipeline protection, heat exchange equipment, etc., can solve the problems of inconvenient installation, low toughness, easy cracking, etc., and achieve improved vibration resistance and heat insulation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for manufacturing a heat insulation block for anti-vibration heat insulation pipe support, which comprises the following steps:

[0056] (1) Preparation before manufacture;

[0057] 1) The ambient temperature for construction should be between 5°C and 35°C. When the ambient temperature is lower than 5°C, antifreeze measures should be taken; when the ambient temperature is higher than 35°C, cooling measures should be taken. The construction process should have good ventilation and Lighting, to prevent exposure to the sun and rain;

[0058] 2.) All equipment must be checked before construction, whether the metal surface has been sandblasted or manually derusted as required, whether all fastenings in the equipment are firm, whether the welding and installation of anchor nails or insulation nails are qualified;

[0059] 3.) Water, rust, oil, slag and other debris on the equipment must be removed before construction, so as not to affect the strength of the material...

Embodiment 2

[0088] A method for manufacturing a heat insulation block for anti-vibration heat insulation pipe support, which comprises the following steps:

[0089] (1) Preparation before manufacture;

[0090] 1) The ambient temperature for construction should be between 5°C and 35°C. When the ambient temperature is lower than 5°C, antifreeze measures should be taken; when the ambient temperature is higher than 35°C, cooling measures should be taken. The construction process should have good ventilation and Lighting, to prevent exposure to the sun and rain;

[0091] 2.) All equipment must be checked before construction, whether the metal surface has been sandblasted or manually derusted as required, whether all fastenings in the equipment are firm, whether the welding and installation of anchor nails or insulation nails are qualified;

[0092] 3.) Water, rust, oil, slag and other debris on the equipment must be removed before construction, so as not to affect the strength of the material...

Embodiment 3

[0121] A method for manufacturing a heat insulation block for anti-vibration heat insulation pipe support, which comprises the following steps:

[0122] (1) Preparation before manufacture;

[0123] 1) The ambient temperature for construction should be between 5°C and 35°C. When the ambient temperature is lower than 5°C, antifreeze measures should be taken; when the ambient temperature is higher than 35°C, cooling measures should be taken. The construction process should have good ventilation and Lighting, to prevent exposure to the sun and rain;

[0124] 2.) All equipment must be checked before construction, whether the metal surface has been sandblasted or manually derusted as required, whether all fastenings in the equipment are firm, whether the welding and installation of anchor nails or insulation nails are qualified;

[0125] 3.) Water, rust, oil, slag and other debris on the equipment must be removed before construction, so as not to affect the strength of the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com