Sintering secondary automatic proportioning control system capable of realizing production cost measurement and control

A production cost and control system technology, applied in the direction of various fluid ratio control, etc., to reduce procurement costs, facilitate tracking, and achieve low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following specific examples further describe the present invention in detail.

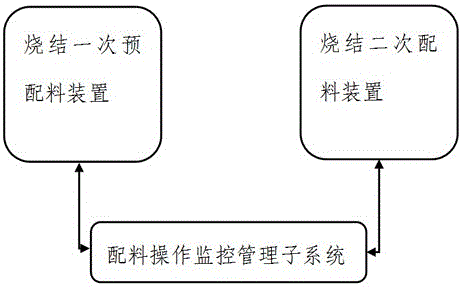

[0057] Such as figure 1 As shown, a sintering secondary automatic batching control system that realizes production cost measurement and control, the control system includes a sintering primary batching device, a sintering secondary batching device and a batching operation monitoring and management subsystem, and the sintering primary batching The device is used to prepare and mix a variety of iron-containing raw materials (including miscellaneous materials) in a certain proportion to obtain iron-containing pre-batching, so as to realize the pre-mixing of iron-containing raw materials and reasonable matching of particle size composition; the sintering secondary batching device realizes the Iron pre-batching, fuel (coke powder, anthracite), flux (quicklime, limestone), cold return ore and other sintered raw materials are accurately batched according to a certain ratio; the batching operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com