Propolis wine preparing technology

A preparation process, a technology of propolis, applied in the field of wine processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

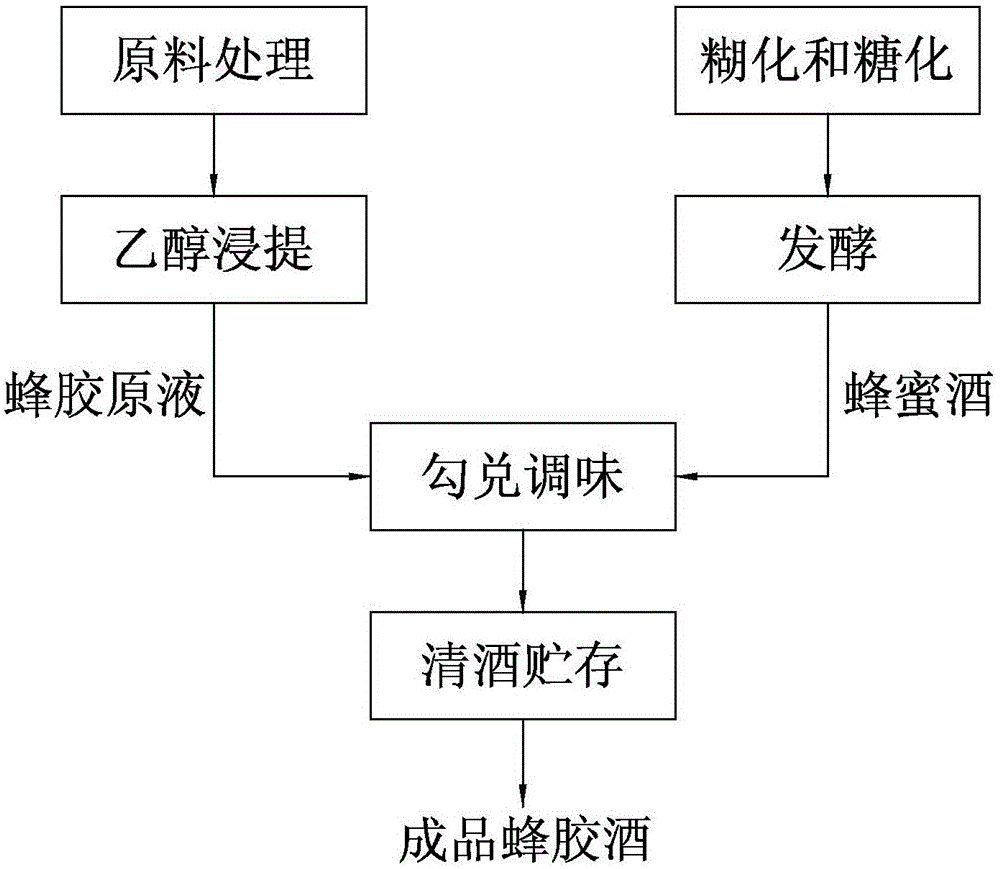

[0061] A kind of propolis wine preparation technology is characterized in that finishing according to the following steps:

[0062] a. Raw material processing: After washing and removing impurities, propolis is frozen at 0°C for 12 hours, sampled during low-temperature drying, crushed in 10 seconds, and the crushed particle size is ≤4mm, collected and sealed, and stored in a -18°C refrigerator for later use.

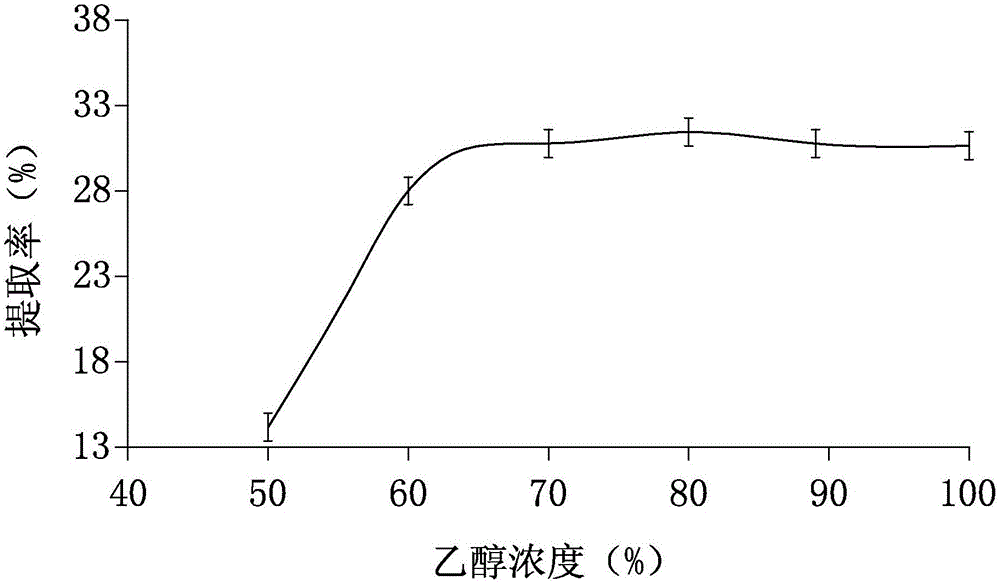

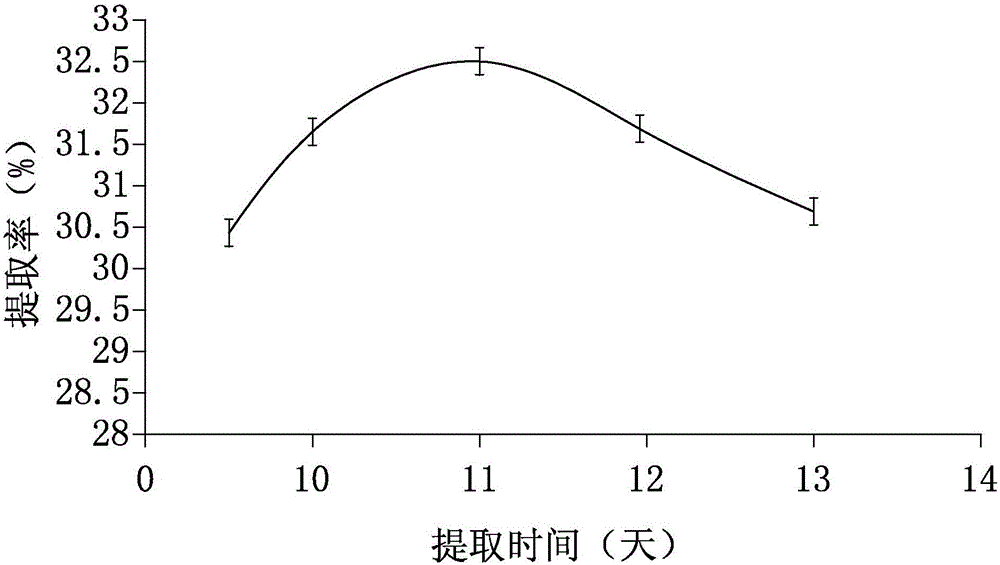

[0063] B, ethanol leaching: in 70% ethanol solution by volume fraction, slowly, evenly add the propolis raw material that pulverizes, and the liquid-to-solid ratio of ethanol solution and propolis raw material is 10mL / g, stir while adding propolis raw material, wait until fully After mixing and dissolving, stop stirring, extract at an extraction temperature of 55°C for 10 days, then separate the material and liquid, the filtrate is the propolis solution, and collect the filter residue for secondary ethanol extraction.

[0064] Secondary ethanol leaching: slowly and evenl...

Embodiment 2

[0072] A kind of propolis wine preparation technology is characterized in that finishing according to the following steps:

[0073] a. Raw material processing: After washing and removing impurities, propolis is frozen at 0°C for 12 hours, sampled during low-temperature drying, crushed in 10 seconds, and the crushed particle size is ≤4mm, collected and sealed, and stored in a -18°C refrigerator for later use.

[0074] B, ethanol leaching: in 90% ethanol solution by volume fraction, slowly, evenly add the propolis raw material that pulverizes, and the liquid-to-solid ratio of ethanol solution and propolis raw material is 20mL / g, stir while adding propolis raw material, wait until fully After mixing and dissolving, stop stirring, extract at 75°C for 12 days, then separate the material and liquid, the filtrate is the propolis solution, and collect the filter residue for secondary ethanol extraction.

[0075] Secondary ethanol leaching: slowly and evenly add the filter residue desc...

Embodiment 3

[0083] A kind of propolis wine preparation technology is characterized in that finishing according to the following steps:

[0084] a. Raw material processing: After washing and removing impurities, propolis is frozen at 0°C for 12 hours, sampled during low-temperature drying, crushed in 10 seconds, and the crushed particle size is ≤4mm, collected and sealed, and stored in a -18°C refrigerator for later use.

[0085] B, ethanol leaching: in the volume fraction is 80% ethanol solution, slowly, evenly add the propolis raw material that pulverizes, and the liquid material ratio that ethanol solution and propolis raw material add is 15mL / g, stir while adding propolis raw material, wait until fully After mixing and dissolving, stop stirring, extract at 65°C for 11 days, then separate the material and liquid, the filtrate is the propolis solution, and collect the filter residue for secondary ethanol extraction.

[0086] Secondary ethanol leaching: slowly and evenly add the filter re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com