Cysteine and citric acid derivative fluorescent powder and preparation method therefor

A cysteine and citric acid technology, applied in the field of fluorescent materials, can solve the problems of low fluorescence quantum yield, troublesome synthesis route, limited raw materials, etc., and achieve the effects of high fluorescence quantum yield, easy amplification, and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 1g of cysteine and 1g of citric acid into a three-necked flask, then add 20ml of oleic acid, stir and heat, and set the temperature to 120°C. When the temperature rises to 80 degrees, the reaction time is 30 minutes, and the color gradually changes from colorless to yellow, and the color deepens as the reaction progresses. After 30 minutes, the reaction was stopped, and the reaction solution was poured out while it was hot. The product was fully washed with n-hexane, and dried in vacuum at 50°C to obtain a cysteine-citric acid composite fluorescent polymer.

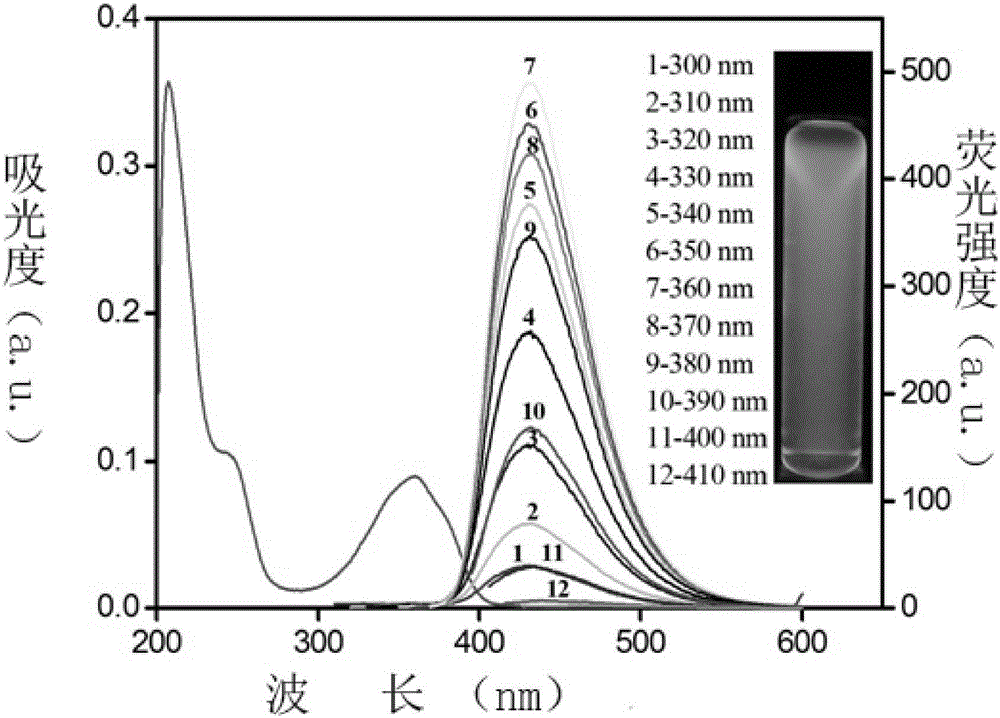

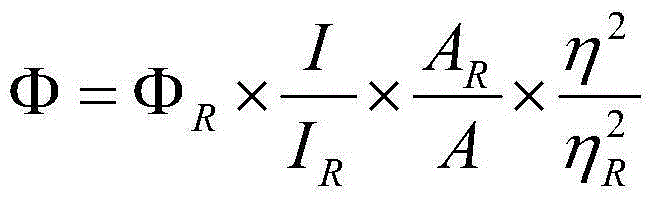

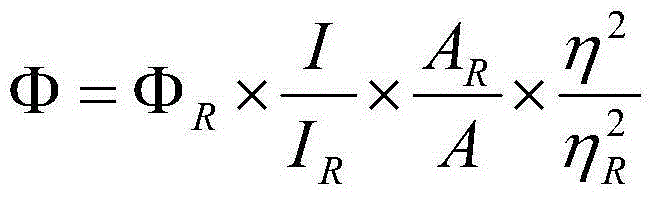

[0036] The fluorescent quantum yield of cysteine and citric acid composite fluorescent polymer in embodiment 1 is measured at room temperature, with quinine sulfate (solvent is the H of 0.1M 2 SO 4 , the quantum yield is 0.56) as a reference, by measuring the fluorescence integral intensity obtained under the same excitation conditions and the ultraviolet absorption value under the excitation wavelength ...

Embodiment 2

[0040] Weigh 1g of cysteine and 1g of citric acid into a three-necked flask, then add 20ml of oleic acid, stir and heat, and set the temperature to 160°C. When the temperature rose to 110°C, the solid dissolved, and the reaction timed for 30 minutes, the color gradually changed from colorless to yellow, and the color deepened as the reaction progressed. After 30 minutes, the reaction was stopped, and the reaction solution was poured out while it was hot. The product was fully washed with n-hexane, and dried in vacuum at 50°C to obtain a cysteine-citric acid composite fluorescent polymer.

[0041] The fluorescent quantum yield of cysteine and citric acid composite fluorescent polymer in embodiment 2 is measured at room temperature, with quinine sulfate (solvent is the H of 0.1M 2 SO 4 , the quantum yield is 0.56) as a reference, by measuring the fluorescence integral intensity obtained under the same excitation conditions and the ultraviolet absorption value under the exci...

Embodiment 3

[0045] The products obtained in Examples 1 and 2 are dissolved in ethanol or acetone, and then coated on a silica gel carrier. The mass ratio of the fluorescent polymer to the mass of the silica gel powder is 0.1-20%, to obtain a luminescent phosphor, which emits light under the irradiation of 365nm ultraviolet light. Bright blue light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com