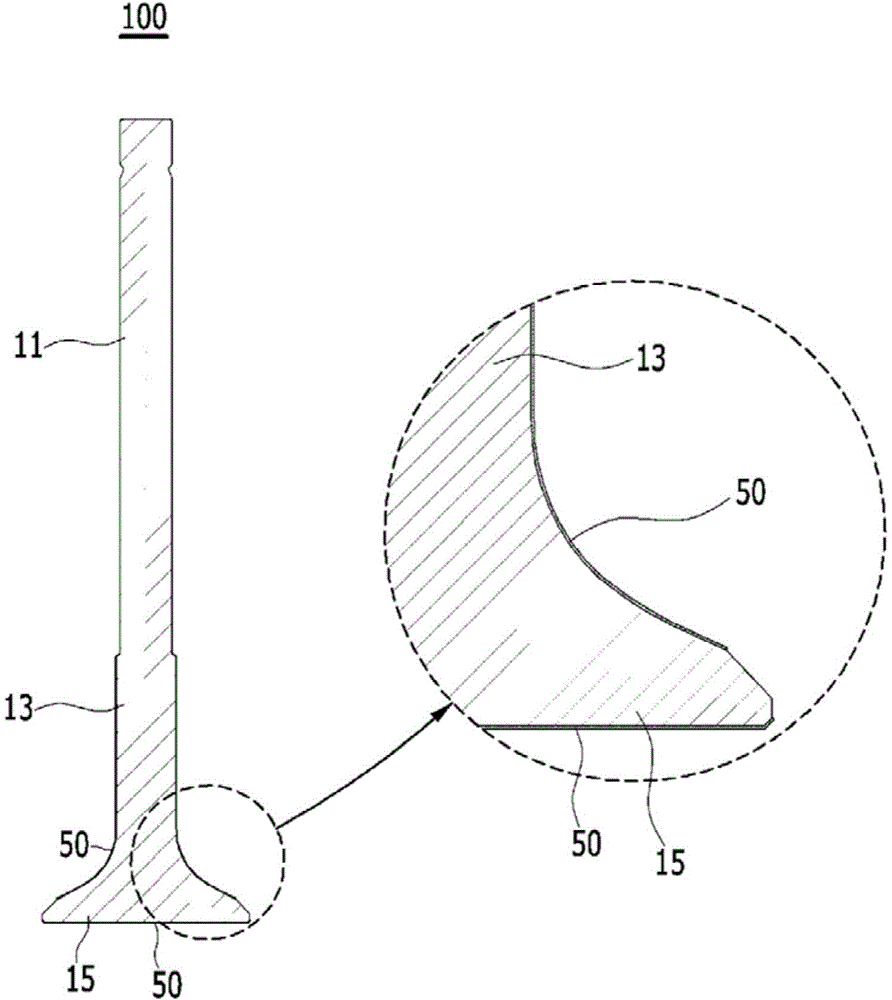

Exhaust valve for engine

A technology for engines and discharge valves, which is applied in the direction of engine components, machines/engines, lift valves, etc., can solve the problems of slow progress in the research of heat insulation materials and heat insulation structures, and achieve the effects of reducing manufacturing costs, improving efficiency, and reducing heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 3

[0097] (1) Manufacturing of heat-insulating coating composition:

[0098] The porous silica aerogel dispersed in ethanol (specific surface area: about 500cm 3 / g) and polyamide-imide resin (product made by SolvaySA, weight-average molecular weight: about 11,000) dispersed in xylene into a 20g reactor, to which zirconia beads (440g) are added, and heated at room temperature Ball milling is performed at a speed of 150 to 300 rpm under the conditions of temperature and normal pressure to produce a heat-insulating coating composition (coating solution).

[0099] In this case, the weight ratio of the porous silica aerogel based on the polyamideimide resin is the same as that described in Table 1 below.

[0100] (2) Formation of thermal insulation coating layer

[0101] The resulting heat-insulating coating composition is applied to a component for a vehicle engine by a spraying method. In addition, the heat-insulating coating composition is applied to the part, and the first semi-drying i...

experiment Embodiment 1

[0111] Experimental Example 1: Measurement of thermal conductivity

[0112] The thermal conductivity of the coating layer on the components obtained from the Examples and Comparative Examples was measured by the thermal diffusion measurement method using the laser flash method under the conditions of room temperature and normal pressure based on ASTM E1461.

experiment Embodiment 2

[0113] Experimental Example 2: Measurement of heat capacity

[0114] The heat capacity was determined by measuring the specific heat of the coating layer on the parts obtained from the Examples and Comparative Examples using a DSC device based on ASTM E1269 and using sapphire as a control under room temperature conditions.

[0115] (Table 1)

[0116]

[0117] As described in Table 1, it was confirmed that the heat-insulating coating layers obtained in Examples 1 to 3 had 1240 KJ / m in a thickness of 120 to 200 μm 3 Heat capacity of K or less and thermal conductivity of 0.54W / m or less. Therefore, the heat-insulating coating layer obtained in Examples 1 to 3 can be applied to the coating of the components of the internal combustion engine to reduce the thermal energy released to the outside and thereby improve the efficiency of the internal combustion engine and the fuel efficiency of the vehicle.

[0118] In addition, the heat-insulating coating layer obtained from Examples 1 to 3 can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com