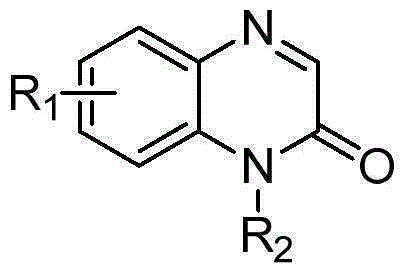

Synthetic method for 2(1H)-quinoxalinone C-3 site phosphate compound

A technology of phosphoric acid compound and synthesis method, applied in the synthesis field of quinoxaline-2-one C-3 phosphoric acid compound, can solve the problems of harsh reaction conditions, complicated reaction steps, long reaction time and the like, and achieves easy post-processing, The effect of green post-treatment and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Example 1

[0022] Preparation of dimethyl (3-oxo-3,4-dihydroquinoxalin-2-yl) phosphate

[0023] Add 0.2 mmol of quinoxaline-2(1H)-one, 0.6 mmol of dimethyl phosphate, 0.6 mmol of potassium persulfate, and 2.0 mL of acetonitrile into a 10 mL reaction tube, and place it in an oil bath at 100°C under air conditions. Reaction for 8h. Stop the reaction and cool to room temperature. The reaction solution was spin-dried with a rotary evaporator, and 46.7 mg of the target product was obtained through column chromatography with a yield of 92%. The characterization of the compound is as follows: 1 HNMR(400MHz,d 6 -DMSO)δ12.79(s,1H),7.89(d,J=8.0Hz,1H), 7.69-7.63(m,1H),7.40-7.33(m,2H), 3.87(d,J=11.1Hz ,6H). 13 CNMR(100MHz,d 6 -DMSO)δ154.5(d,J C-P =31.4Hz),153.8(d,J C-P =223.8Hz), 133.5(s), 133.2(d, J C-P =2.9Hz),132.0(d,J C-P =25.3Hz), 130.3(s), 124.3(s), 116.3(s), 54.5(d, J C-P =6.3Hz). 31 PNMR(162MHz, d 6 -DMSO)δ9.4(s).HRMSm / z(ESI)calculatedforC 10 H 11 N 2 O 4 P(M+H) + 255.0...

Example Embodiment

[0024] Example 2

[0025] Preparation of diethyl (3-oxo-3,4-dihydroquinoxalin-2-yl) phosphate

[0026] Add 0.2mmol of quinoxaline-2(1H)-one, 0.6mmol of diethyl phosphate, 0.6mmol of potassium persulfate, and 2.0mL of acetonitrile into a 10mL reaction tube, and place it in an oil bath at 100°C under air conditions. Reaction for 8h. Stop the reaction and cool to room temperature. The reaction solution was spin-dried with a rotary evaporator, and 47.9 mg of the target product was obtained through column chromatography with a yield of 85%. The characterization of the compound is as follows: 1 HNMR(400MHz,d6-DMSO)δ12.78(s,1H), 7.88(d,J=7.9Hz,1H), 7.70–7.63(m,1H), 7.42–7.31(m,2H), 4.26(dq , J1=14.2Hz, J2=7.1Hz, 4H), 1.32(t, J=7.0Hz, 6H). 13 CNMR(100MHz,d6-DMSO)δ154.4(d,JC-P=31.4Hz), 154.2(d,JC-P=222.9Hz), 133.4(s), 133.2(d,JC-P=2.6Hz) ,131.9(d,JC-P=25.2Hz),130.3(s),124.3(s),116.3(s),63.8(d,JC-P=6.2Hz),16.8(d,JC-P=6.1Hz ). 31 PNMR(162MHz,d6-DMSO)δ7.0(s).HRMSm / z(ESI) calculated for C1...

Example Embodiment

[0027] Example 3

[0028] Preparation of diisopropyl (3-oxo-3,4-dihydroquinoxalin-2-yl) phosphate

[0029] Add 0.2 mmol of quinoxaline-2(1H)-one, 0.6 mmol of diisopropyl phosphate, 0.6 mmol of potassium persulfate, and 2.0 mL of acetonitrile into a 10 mL reaction tube, and place it in an oil bath at 100°C. Under the conditions, the reaction is 8h. Stop the reaction and cool to room temperature. The reaction solution was spin-dried with a rotary evaporator and separated by column chromatography to obtain 41.8 mg of the target product with a yield of 67%. The characterization of the compound is as follows: 1 HNMR(400MHz,d 6 -DMSO)δ12.74(s,1H),7.85(d,J=7.9Hz,1H), 7.69-7.63(m,1H), 7.37(dd,J 1 = 14.1, J 2 =7.4Hz,2H),4.82(dq,J 1 = 12.4, J 2 =6.2Hz,2H),1.35(dd,J=6.0Hz,J 2 =4.7Hz,12H). 13 CNMR(100MHz,d 6 -DMSO)δ154.6(d,J C-P =223.5Hz),154.3(d,J C-P =31.4Hz), 133.2(s), 133.1(d, J C-P =2.6Hz), 130.2(s), 124.3(s), 116.2(s), 72.23(d, J C-P =6.2Hz),24.57(d,J C-P =3.2Hz),23.91(d,J C-P =6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com