Method for preparing ceramic through micro-nano grain-size grading

A technology of micro-nano and ceramics, which is applied in the field of preparation of ceramics by micro-nano powder grading technology, can solve the problems that the comprehensive performance of ceramic materials cannot be effectively improved, and it is difficult to obtain relatively high-density ceramic green bodies and sintered bodies. Uniform and dense stacking, dense stacking, and performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

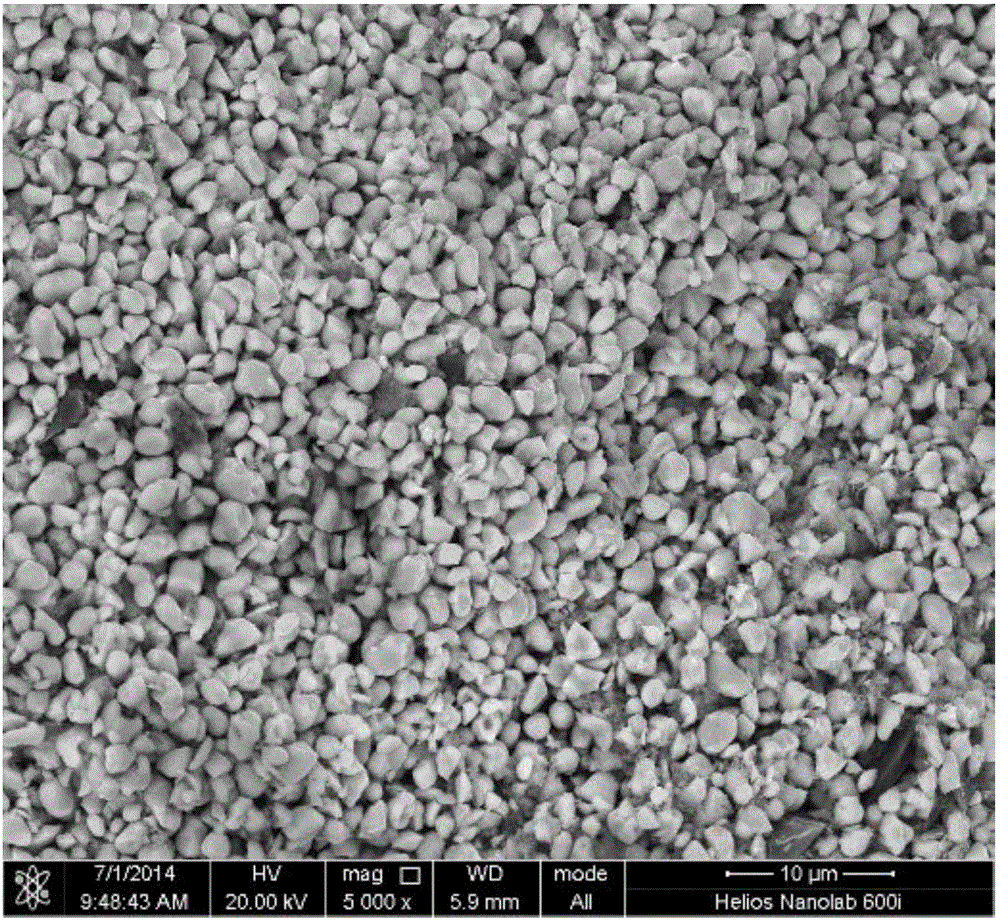

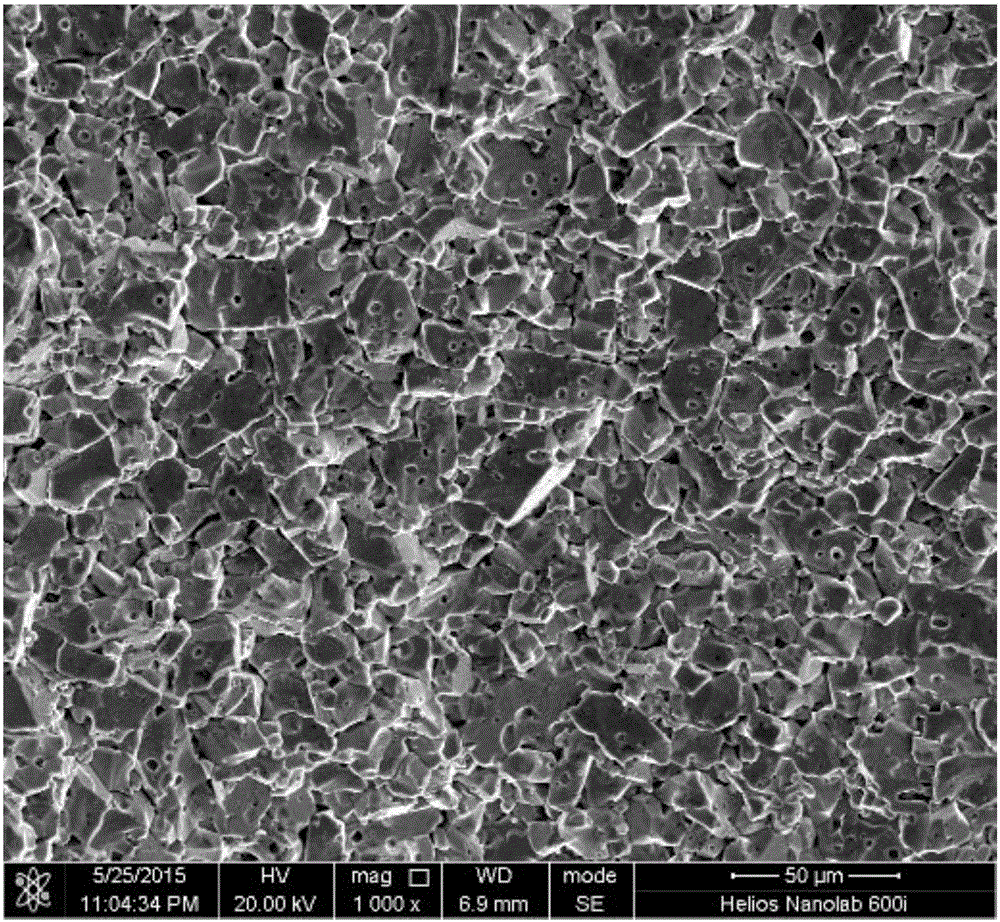

[0034] Specific implementation mode one: a kind of method of adopting micro-nano particle size gradation to prepare ceramics in the present embodiment, it is carried out according to the following steps:

[0035] 1. Prepare a uniform mixed solution: first dissolve the organic monomer and crosslinking agent in deionized water, adjust the pH value of the solution, and then perform ultrasonic treatment to obtain a uniformly mixed colloidal solution;

[0036] The content of the organic monomer accounts for 2% to 10% of the mass of deionized water;

[0037] The mass ratio of the organic monomer to the crosslinking agent is (8~20):1;

[0038] The pH value is adjusted to 5-12;

[0039] 2. Preparation of single-phase or multi-phase ceramic slurry: to the colloidal solution obtained in step 1, add micro-nano ceramic powder to prepare single-phase ceramic slurry or add micro-nano matrix ceramic powder and second phase micron ceramic powder to prepare Multi-phase ceramic slurry, then a...

specific Embodiment approach 2

[0054] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the monomer described in step 1 is acrylamide, polyoxyethylene ether, polyethylene glycol methacrylate or N,N-dimethyl Acetylacetamide. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0055] Embodiment 3: This embodiment is different from Embodiment 1 in that the crosslinking agent described in step 1 is N,N-methylenebisacrylamide, polyacrylate or diisocyanate. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com