Internal-circulation type iron-carbon micro-electrolysis reactor

An iron-carbon micro-electrolysis and internal circulation technology, applied in the direction of sterilization/microdynamic water/sewage treatment, etc., can solve the problems of easy passivation and hardening of iron filings, low treatment efficiency, high energy consumption, etc., and achieve continuous and efficient treatment and operation Simple, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

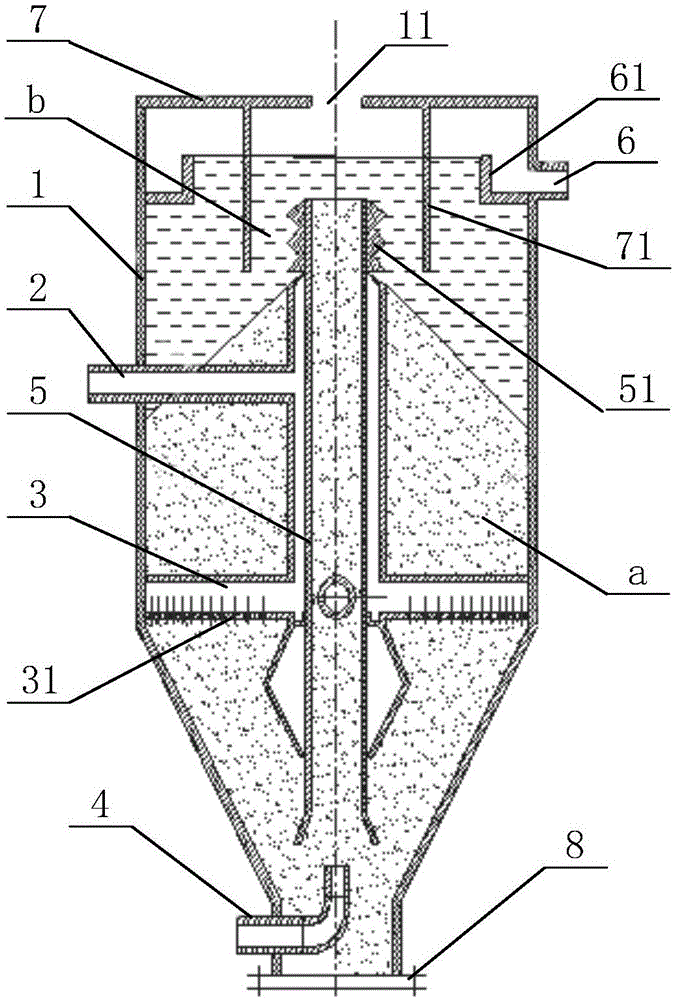

[0027] (1) The top of the cylindrical body 1 is preferably provided with a steady flow cover 7; the cylinder air outlet 11 is vertically located in the middle of the steady flow cover 7; the bottom of the steady flow cover 7 is vertically provided with an annular partition 71; The partition 71 separates the top opening of the internal circulation pipe 5 from the cylinder water outlet 6 , and the bottom end of the annular partition 71 is lower than the top opening of the internal circulation pipe 5 . When the aeration bubbles drive the iron-carbon filler a to be discharged from the top opening of the internal circulation pipe 5, the purified water at the top opening of the internal circulation pipe 5 will have large fluctuations, and the annular partition 71 can play a good role in stabilizing the flow function, and can effectively prevent the iron-carbon filler a from splashing out of the water outlet 6 of the cylinder.

[0028] (2) The part of the cylinder body water outlet 6...

Embodiment 1

[0038] The internal circulation iron-carbon micro-electrolysis reactor described in the above technical scheme is used to carry out pre-purification treatment on the simulated dye sewage and the actual dye sewage respectively. The specific treatment process is as follows: first use sulfuric acid to reduce the pH value of the dye sewage to 2.0~4.0, then pass in the internal circulation type iron-carbon micro-electrolysis reactor provided by the present invention; The dye sewage is evenly dispersed to the iron-carbon filler a (the volume ratio of iron and carbon in the cylinder body 1 bottom) through the water distributor 3 1:1), and move upward through the gap of iron-carbon filler a; iron-carbon filler a is aerated and circulated in the internal circulation type iron-carbon micro-electrolysis reactor, and can be completed after 1-2 hours of treatment Pre-purification treatment of dye wastewater. Furthermore, alkali can be added to the pre-purified dye sewage, and then the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com