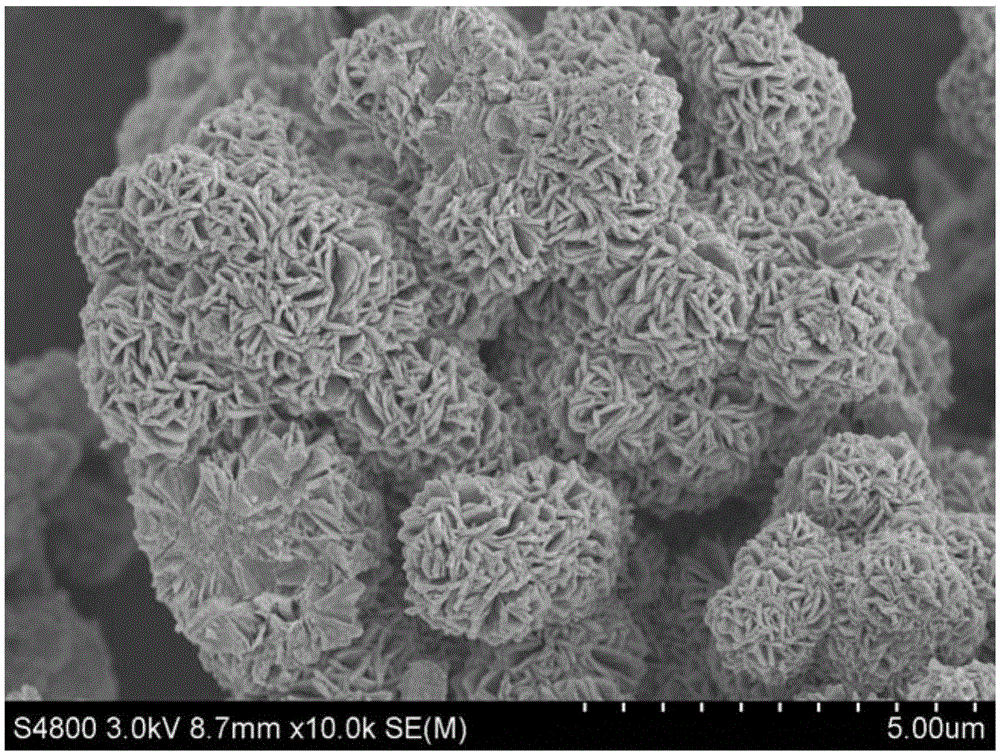

Preparation method of multi-dimensional pure-phase W18O49

A pure-phase, multi-dimensional technology, applied in nanotechnology for materials and surface science, tungsten oxide/tungsten hydroxide, nanotechnology, etc., can solve the problem of material morphology, poor crystallinity, low product purity, sintering High temperature and other problems, to achieve the effect of controllable shape and size, high purity and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) 0.7852g of analytically pure WCl 6 Add it to 40mL of absolute ethanol to prepare a solution, and seal it with plastic wrap in time to avoid contact with air.

[0033] 2) Stir the solution with a magnetic stirrer for 30 minutes. After the solution gradually changes from yellow to blue, perform ultrasonic (60 Hz) treatment for 30 minutes to obtain a uniformly mixed solution;

[0034] 3) Pour the uniformly mixed solution into a 100mL autoclave lined with polytetrafluoroethylene, and the volume filling ratio is controlled at 40%; feed 30min of N into the autoclave 2 To reduce the oxygen in the reactor, then put the sealed reactor into a homogeneous reactor, and react at 160°C for 24 hours.

[0035] 4) After the reaction is completed, cool down to room temperature with the furnace, centrifuge and wash the final reactant with absolute ethanol for 3 times, put the centrifuged material in a vacuum oven and dry at 40°C for 12 hours to obtain a multidimensional pure phase W ...

Embodiment 2

[0039] 1) 0.5968g of analytically pure WCl 6 Add it to 50mL of isopropanol to prepare a solution, and seal it with plastic wrap in time to avoid contact with air.

[0040] 2) Stir the solution with a magnetic stirrer for 20 minutes. After the solution gradually changes from yellow to blue, perform ultrasonic (60 Hz) treatment for 40 minutes to obtain a uniformly mixed solution;

[0041] 3) Pour the homogeneously mixed solution into a 100 mL polytetrafluoroethylene-lined autoclave, keeping the volume filling ratio at 50%. Introduce 20min of N into the reactor 2 To reduce the oxygen in the reactor, then put the sealed reactor into a homogeneous reactor, and react at 170°C for 6h.

[0042] 4) After the reaction is completed, cool down to room temperature with the furnace, and centrifuge and wash the final reactant with absolute ethanol for 5 times. The centrifuged material was dried in a vacuum oven at 60°C for 3 hours to obtain a multidimensional pure phase W 18 o 49 .

[...

Embodiment 3

[0045] 1) 0.8328g of analytically pure WCl 6 Add it to the mixture of absolute ethanol and isopropanol to prepare a solution, and seal it with plastic wrap in time to avoid contact with air. Wherein, in the mixture of absolute ethanol and isopropanol, the volume ratio of absolute ethanol:isopropanol=1:1, and each of absolute ethanol and isopropanol is 20 mL.

[0046] 2) Stir the solution with a magnetic stirrer for 40 minutes. After the solution gradually changes from yellow to blue, perform ultrasonic (60 Hz) treatment for 40 minutes to obtain a uniformly mixed solution;

[0047] 3) Pour the homogeneously mixed solution into a 100 mL polytetrafluoroethylene-lined autoclave, keeping the volume filling ratio at 40%. Introduce 20min of N into the reactor 2 To reduce the oxygen in the reactor, then put the sealed reactor into a homogeneous reactor, and react at 160°C for 18h.

[0048] 4) After the reaction is completed, cool down to room temperature with the furnace, and centr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com