High-capacity reversible hydrogen storage composite material of LiBH4 doped fluoride, and preparation method thereof

A composite material and fluoride technology, applied in the field of materials, can solve the problems of poor cycle hydrogen discharge performance and high hydrogen discharge temperature, and achieve the effect of simple process and good cycle hydrogen discharge ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] LiBH 4 Doped NbF 5 Preparation of high-capacity reversible hydrogen storage composites

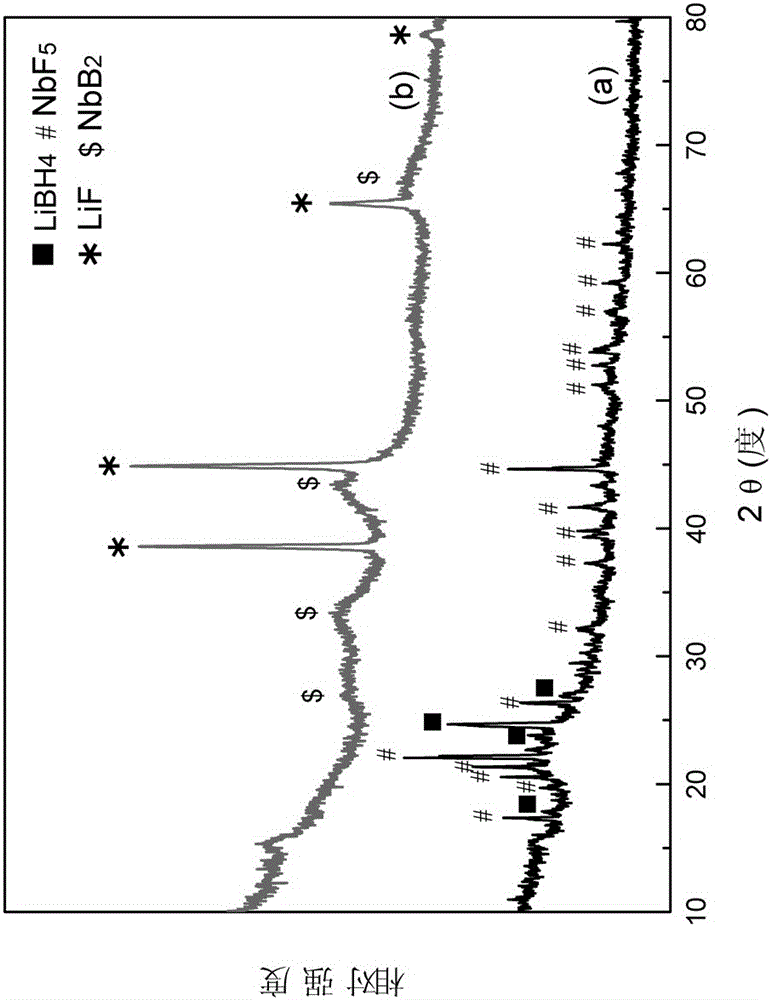

[0032] In a glove box filled with flowing high-purity argon, weigh LiBH at a molar ratio of 5:1 4 and NbF 5The two components are then put into a stainless steel ball mill tank with a volume of 100ml. Under a ball-to-material ratio of 30:1, a rotating speed of 300rpm and an argon atmosphere, use a high-energy planetary ball mill for ball milling for 1min to obtain a ball-milled mixture, namely for LiBH 4 Doped NbF 5 The high-capacity reversible hydrogen storage composite material, its XRD pattern is as follows figure 1 Shown in curve a.

[0033] From figure 1 It can be seen from the XRD figure of a that under the conditions of the present embodiment, LiBH 4 and NbF 5 Only simple uniform mixing occurs, and the phase diffraction peaks of the two are clearly visible.

Embodiment 2

[0035] LiBH 4 Doped NbF 5 Hydrogen desorption of high-capacity reversible hydrogen storage composites

[0036] In a glove box filled with flowing high-purity argon, weigh LiBH at a molar ratio of 5:1 4 and NbF 5 Put the two components into a stainless steel ball mill tank, and use a high-energy planetary ball mill to mill for 1 minute at a ball-to-material ratio of 40:1, a speed of 400 rpm, and an argon atmosphere to obtain a milled mixture, which is 5LiBH 4 -NbF 5 High-capacity reversible hydrogen storage composites.

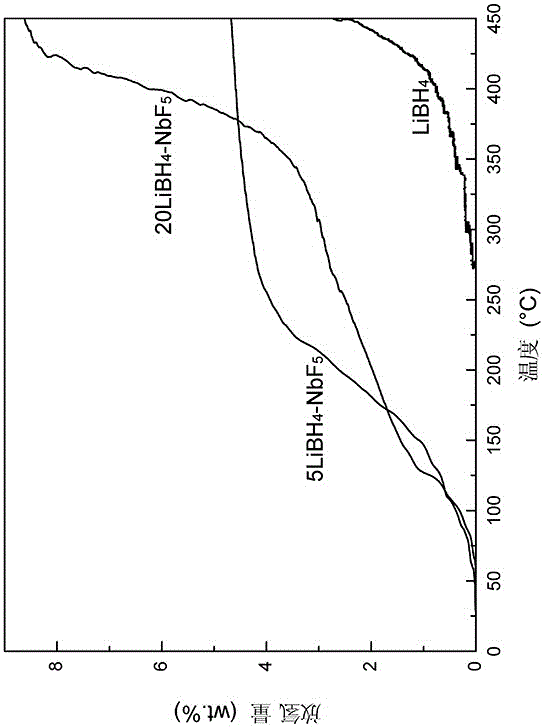

[0037] The 5LiBH prepared in this embodiment 4 -NbF 5 The curve of the hydrogen release capacity of the high-capacity reversible hydrogen storage composite material as a function of temperature is as follows: figure 2 shown, from figure 2 As can be seen in the 5LiBH 4 -NbF 5 The initial hydrogen desorption temperature of the composite is about 60 °C, while the undoped NbF 5 LiBH 4 The initial hydrogen desorption temperature is about 270°C. Through...

Embodiment 3

[0040] LiBH 4 Doped NbF 5 DSC-MS results of high-capacity reversible hydrogen storage composites

[0041] In a glove box filled with flowing high-purity argon, weigh LiBH at a molar ratio of 5:1 4 and NbF 5 The two components are put into a stainless steel ball mill jar with a volume of 100ml, and are ball milled with a high-energy planetary ball mill for 1min at a ball-to-material ratio of 30:1, a rotating speed of 400rpm and an argon atmosphere to obtain a ball-milled mixture, namely 5LiBH 4 -NbF 5 High-capacity reversible hydrogen storage composites.

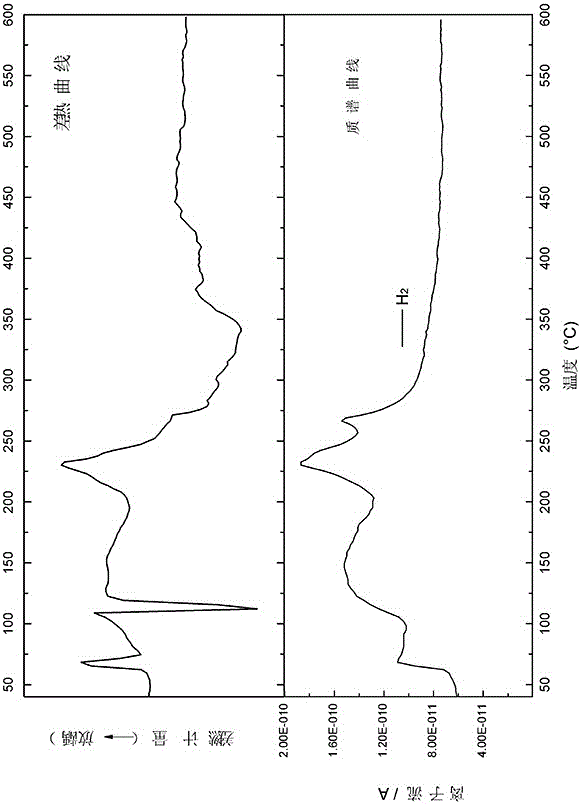

[0042] The 5LiBH prepared in this embodiment 4 -NbF 5 The hydrogen release amount of the complex changes with temperature DSC-MS (ie, differential thermal-mass spectrometry curve) results are as follows image 3 As shown, it can be seen from the MS (mass spectrum) curve that the signal of hydrogen gas can be detected at about 60°C, indicating that 5LiBH 4 -NbF 5 The complex starts to release hydrogen at this tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com