Special sealing performance test bag for hydrogen peroxide plasma sterilization

A plasma and hydrogen peroxide technology, applied in the field of medical supplies, can solve the problems of cumbersome operation steps, reduced verification accuracy, etc., and achieve the effects of uniform size, clear instructions and easy interpretation, and reduced use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

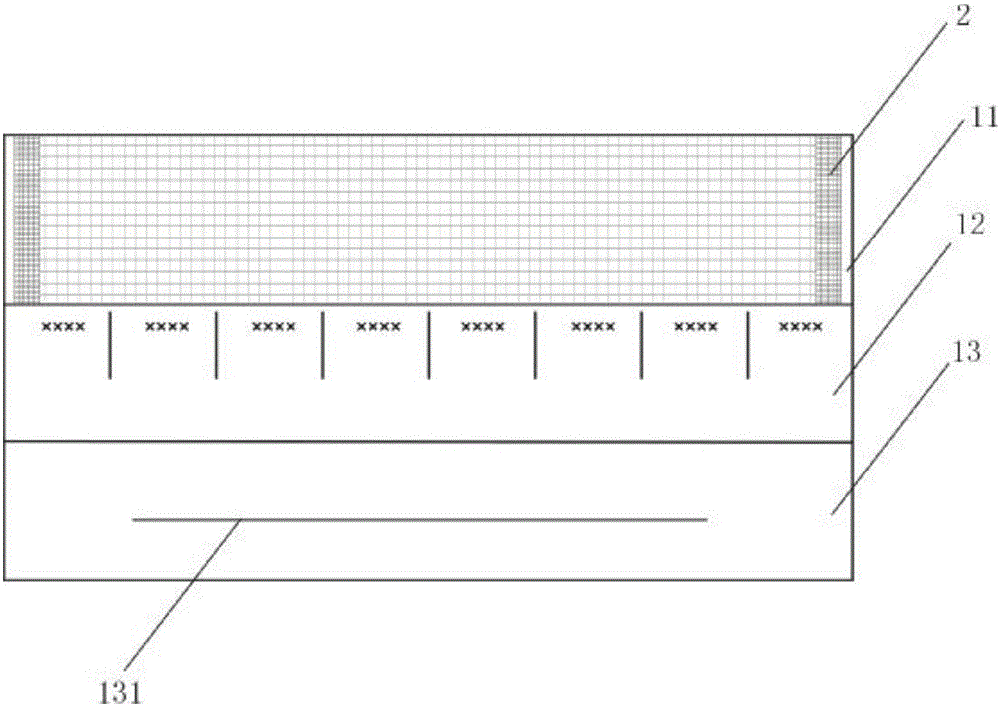

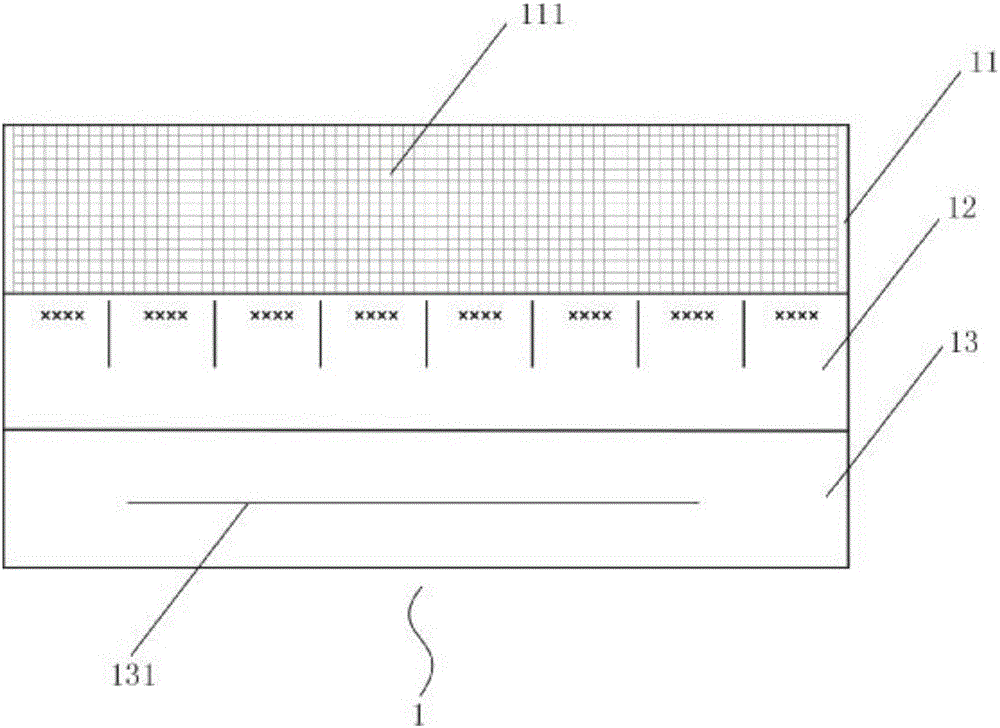

[0020] A special sealing performance test bag for hydrogen peroxide plasma sterilization, made of rectangular high-density polyethylene non-woven fabric 1 and transparent PET / PE composite film 2, heat-pressed and edge-sealed on both sides, high-density polyethylene non-woven fabric 1 The length is 200mm and the width is 105mm. It is divided into three adjacent rectangular areas from top to bottom, which are test area 11, test parameter recording area 12 and blank binding area 13. For the white exterior, a printing grid 111 with 80 lines is printed with environmentally friendly water-based common ink, and the width of the printing grid area is 40 mm. The transparent PET / PE composite film 2 is the same size as the printing grid 111. Grid 111 area above.

[0021] The test parameter recording area 12 is horizontally arranged with a date information colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com