Injection mold and injection molding process of thin-walled backlight box for medical imaging X-ray film

A technology of medical imaging and injection molding, which is applied in the injection molding process of thin-walled injection molding, and in the field of injection molds for thin-walled backlight boxes of medical imaging X-ray films. It can solve the problems of increasing operating costs of enterprises, affecting the quality of finished products, and large internal stress of products , achieve the effect of shortening the injection molding cycle, reducing operating costs, and shortening the process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] S1, raw material drying, drying the raw material in an oven with a drying temperature of 80-90°C for 2-4 hours;

[0029] S2, plastisol, feed the dried raw material into the injection molding machine, and heat it to the plasticizing temperature of 230°C~255°C within 4~5s, and set the operating parameters of the injection molding machine as the first stage sol The speed is 75%, the sol speed of the second stage is 60%, the sol speed of the third stage is 42%, the sol pressure of the three stages is 120 Kg / cm 3 ;

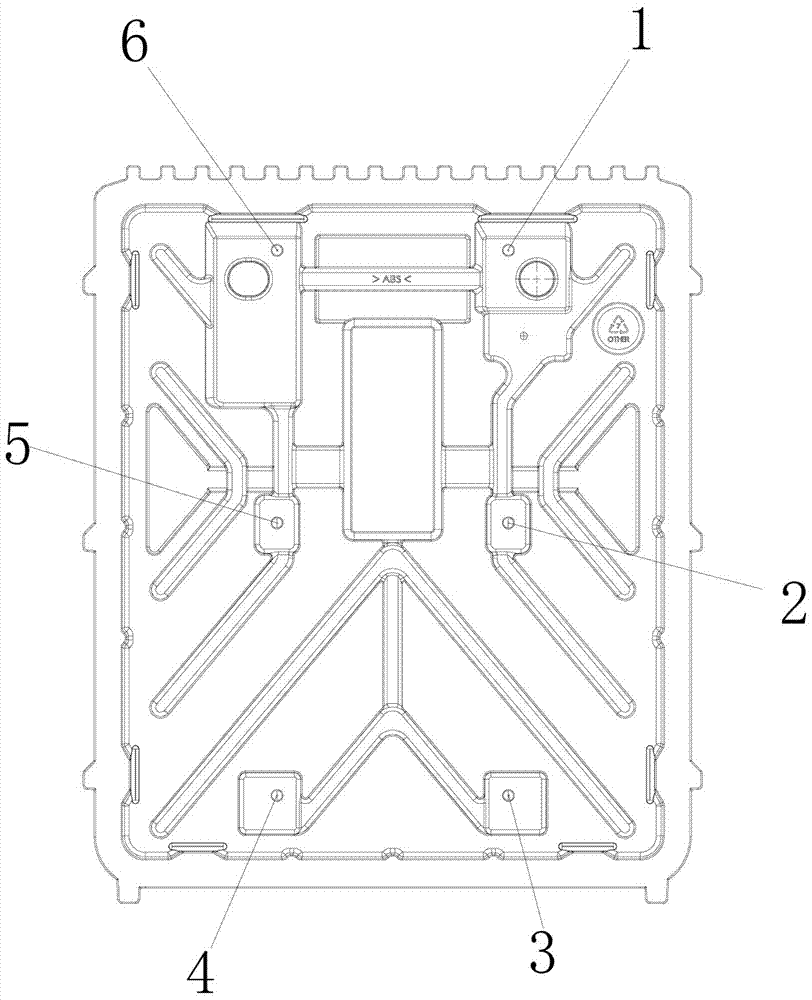

[0030] S3. Injection, the plasticized liquid flow is injected from the injection port of the mold into the cavity through the nozzle of the injection molding machine, and is injected from the first injection port 1 and the second injection port at the same time The injection port 2, the third injection port 3, the fourth injection port 4, and the fifth injection port 5 are injected into the cavity for 1.6~2s, and after an interval of 0.5s, at the same injection...

Embodiment 2

[0040] The difference with embodiment 1 is only that the glue injection process is different:

[0041] S3. Injecting glue, the plasticized liquid flow is injected from the injection port of the mold into the cavity through the nozzle of the injection molding machine, and the glue is injected from the first injection port at 0.8~1.2 under the following injection pressure and injection speed. s, after an interval of 0.1s, inject glue from the second injection port for 0.8~1.2s, after an interval of 0.1s, inject glue from the third injection port for 0.8~1.2s, after an interval of 0.1s, inject glue from the fourth injection port for 0.8~ 1.2s, after an interval of 0.1s, inject glue from the fifth injection port for 0.8~1.2s, after an interval of 0.1s, inject glue from the sixth injection port 6 into the cavity for 1.6~2s.

[0042] Among them, there are four stages of injection pressure and injection speed, the first stage injection pressure is 130~140Kg / cm 3 , the injection spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com