Method for manufacturing high-performance in-situ TiC reinforced titanium-based composite workpiece on basis of CNTs and laser additive manufacturing and processing technology

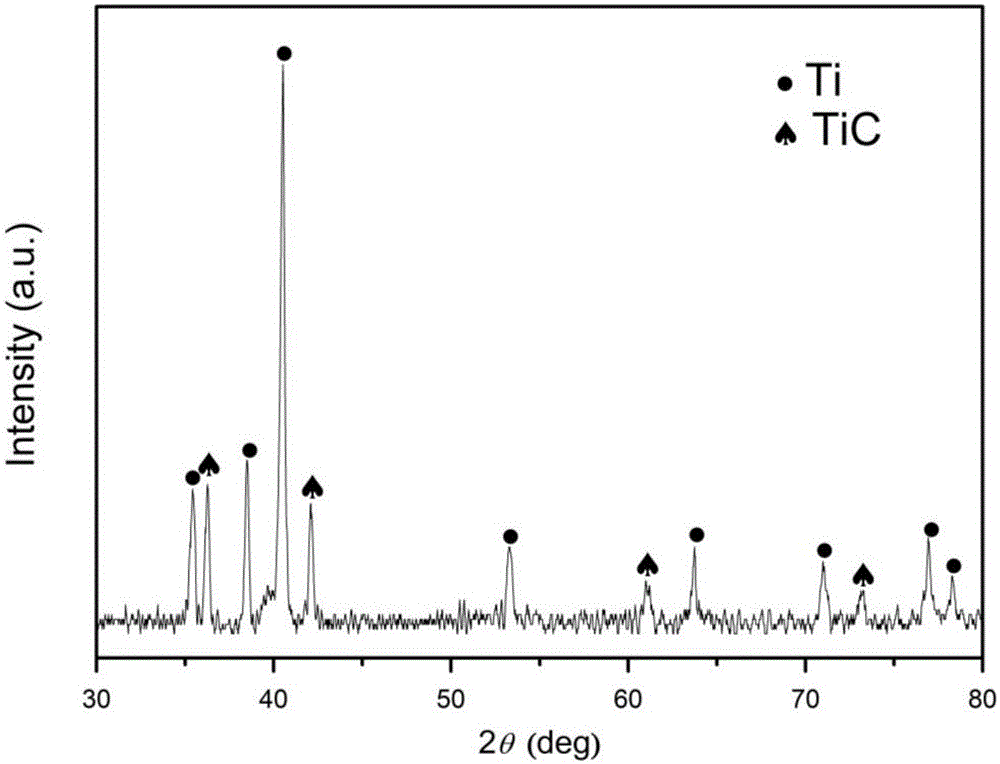

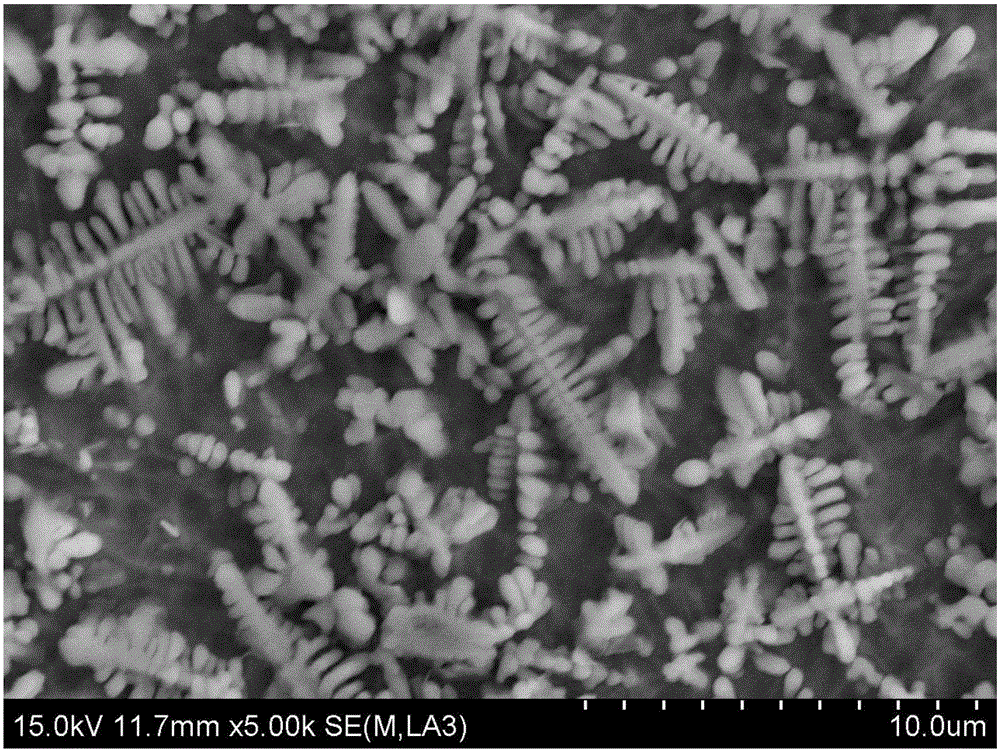

A titanium-based composite material and laser additive technology, applied in the fields of material science and engineering, and mechanical engineering, can solve the problems of weakened reinforcement effect, coarse reinforcement phase particles, and difficult dispersion of CNTs, so as to improve comprehensive mechanical properties and improve laser absorption. rate, the effect of rapid solidification properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

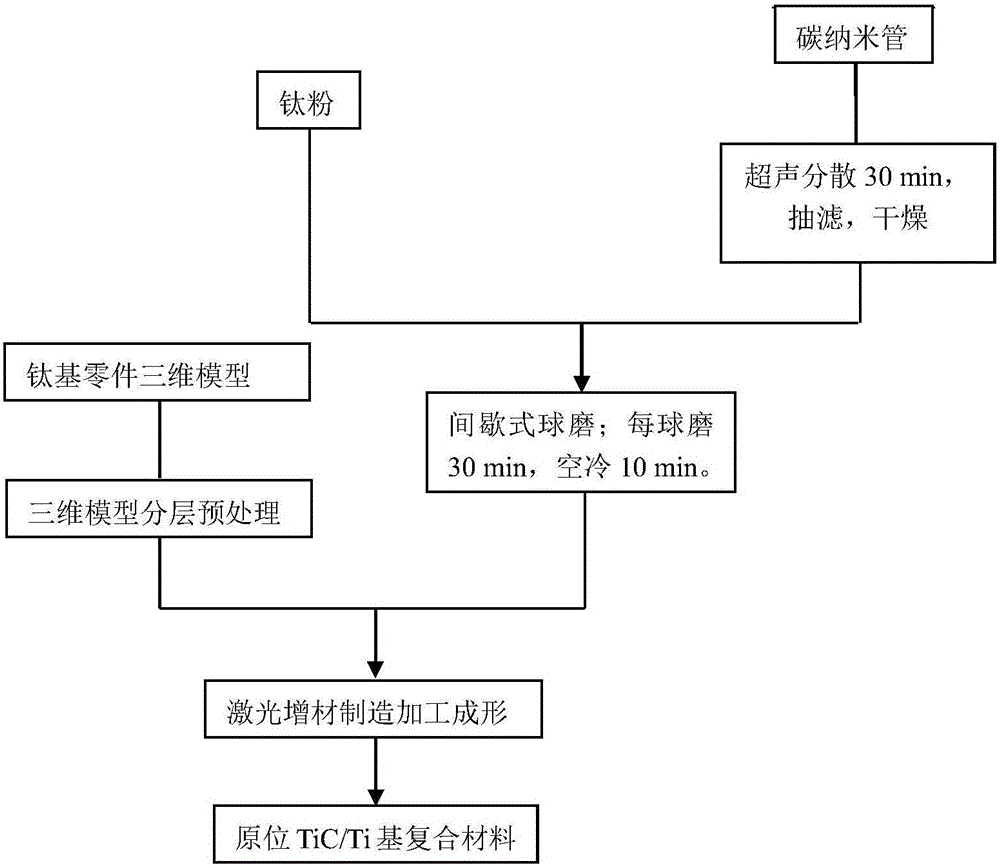

[0038] (1) Carry out pre-ultrasonic dispersion treatment on the carbon nanotubes, add them into ethanol, ultrasonically disperse at room temperature for 30 min, then suction filter and dry.

[0039] (2) Mix pure titanium powder with a purity of more than 99.7% and an average particle size of 45-75 μm with ultrasonically dispersed carbon nanotubes, wherein the carbon nanotubes account for 1 wt.% of the total content of the mixture. The mixture is ball milled in a single-pot star-type high-energy ball mill. The ball milling medium adopts stainless steel balls with a diameter of Φ8-10mm. The ratio of balls to powder is 5:1-10:1, and the speed is 350r / min. 4~8h, each ball milling 30min, air cooling 10min.

[0040] (3) The laser additive manufacturing method is used to form the powder after ball milling, and the argon gas is used for protection during the forming process; the powder is placed in the powder supply device, and the three-dimensional specimen model is layered and sliced ...

Embodiment 2

[0042] The difference between this embodiment and specific embodiment 1 is that when the mixture is proportioned in step (2), the content of carbon nanotubes is controlled at 3wt.%; in step (3), the laser power is set to 90W, and the scanning The speed is set at 100mm / s, and the others are the same as in Embodiment 1.

Embodiment 3

[0044] The difference between this embodiment and Embodiment 2 is that the scanning speed is set to 200 mm / s in step (3), and the others are the same as Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com