Portable internal irradiation particle device and its manufacturing mold and manufacturing method

A technology of manufacturing molds and radiating particles, which is applied in the field of medical stents, can solve the problems that the long-term curative effect of cholangiocarcinoma is not optimistic, and stents can only be used as palliative treatment, so as to achieve the effect of improving efficiency and success rate, good treatment effect and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

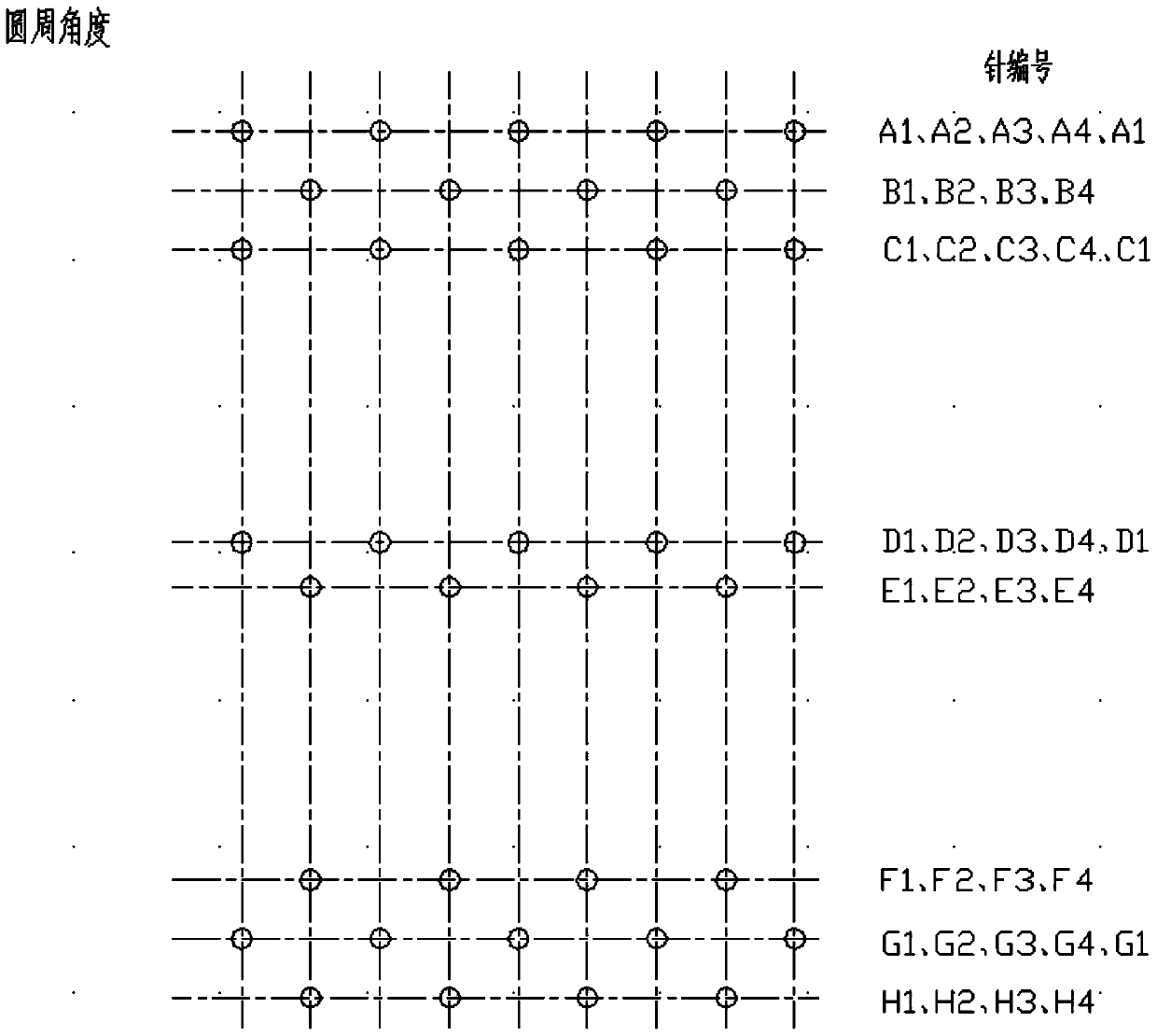

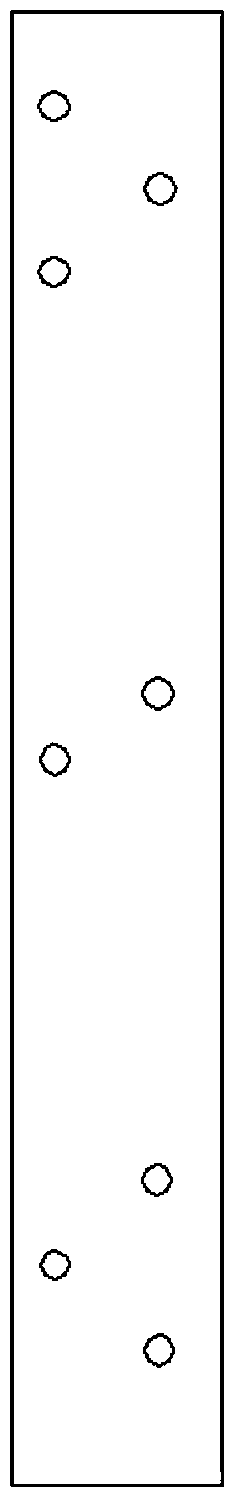

[0044] A manufacturing mold for externally carrying a particle device includes a cylindrical structure of the mold, and four circular holes are distributed in several rows on the circumference of the cylindrical structure of the mold.

Embodiment 3

[0046] A method for manufacturing an external particle device, comprising the steps of:

[0047] Step 1, inserting a fixed needle at each circular hole 9 of the manufacturing mold of the external particle device as claimed in claim 4, for supporting the nickel-titanium alloy wire;

[0048] Step 2. Fix the nickel-titanium alloy wire at one end, and select any fixed needle in the second row as the starting knitting point;

[0049]Step 3. When weaving, the nickel-titanium alloy wire is woven clockwise or counterclockwise, and one device can only weave in one direction all the time;

[0050] Step 4. In the same weaving direction as step 3, weave from top to bottom; when weaving, when encountering the position where nickel-titanium alloy wire has been woven, the newly knitted nickel-titanium alloy wire and the original nickel-titanium alloy wire are interlaced; weave from the top to the bottom, and then weave again from bottom to top;

[0051] Step 5. Repeat the weaving method fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com