Method for crisping eucheuma

An Eucheuma, embrittlement technology, applied in the field of food processing, can solve the problems of food quality and appearance degradation, food quality and appearance quality degradation, colloidal substances are easy to dissolve, etc., to reduce production capacity pollution, reduce energy consumption, reduce The effect of water activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

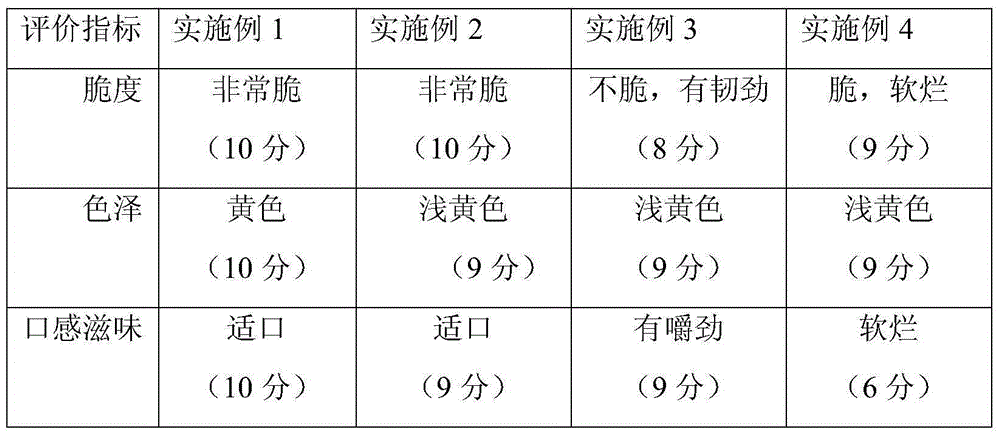

Examples

Embodiment 1

[0024] Wash and soak the unicorn vegetables to remove impurities, until there is no sediment and the water is clear. Dry the washed unicorn vegetables for later use. Weigh 500 g of dried kylin cabbage, add water 35 times its dry weight, stir and let stand. Then 4.5 g of cellulase powder was added, and the water bath was stirred at 50°C for 50 min. After the enzymatic hydrolysis reaction, the temperature of the water bath was increased to 85-90 °C for pasteurization for 10 min. The heat-treated Kirin cabbage was taken out for centrifugal dehydration, and centrifuged at 4000 rpm for 5 min using a centrifuge. After centrifugation, the moisture content of kylin cabbage was 63.7%, and the embrittled kylin cabbage was prepared.

Embodiment 2

[0026] Wash and soak the unicorn vegetables to remove impurities, until there is no sediment and the water is clear. Dry the washed unicorn vegetables for later use. Weigh 500 g of dried and broken Kirin cabbage, add water 30 times its dry weight, stir and let stand. Then 6 g of cellulase powder was added, and the water bath was stirred at 50 °C for 60 min. After the enzymatic hydrolysis reaction, the temperature of the water bath was increased to 85-90 °C for pasteurization for 10 min. The heat-treated Kirin cabbage was taken out for centrifugal dehydration, and centrifuged at 4000 rpm for 5 min using a centrifuge. After centrifugation, the moisture content of kylin cabbage was 65.3%, and the embrittled kylin cabbage was prepared.

Embodiment 3

[0028] Wash and soak the unicorn vegetables to remove impurities, until there is no sediment and the water is clear. Dry the washed unicorn vegetables for later use. Weigh 500 g of dried and broken Kirin cabbage, add water 35 times its dry weight, stir and let stand. Then 3 g of cellulase powder was added, and the water bath was stirred at 50° C. for 30 min. After the enzymatic hydrolysis reaction, the temperature of the water bath was increased to 85-90 °C for pasteurization for 10 min. The heat-treated Kirin cabbage was taken out for centrifugal dehydration, and centrifuged at 4000 rpm for 5 min using a centrifuge. After centrifugation, the moisture content of kylin cabbage was 77.1%, and the embrittled kylin cabbage was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com