Imidacloprid suspension and preparation method thereof

A technology of imidacloprid and suspending agent, which is applied in the field of pesticides and can solve problems such as drug effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

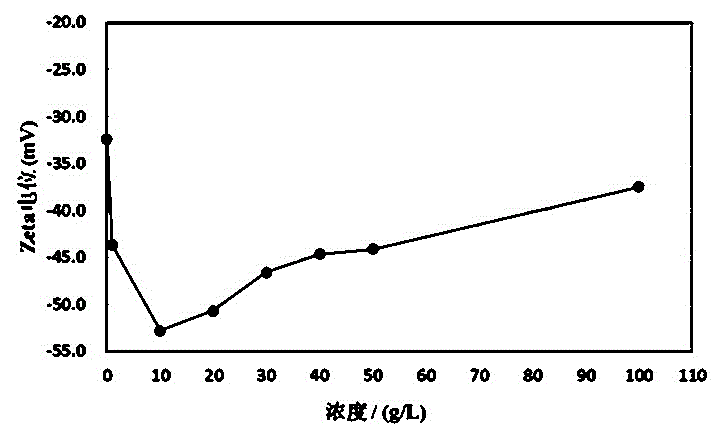

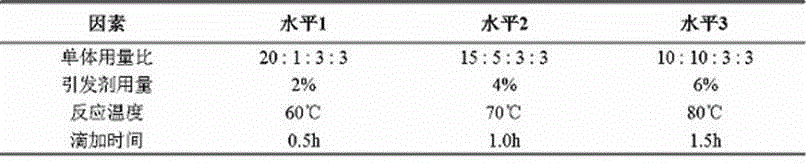

Method used

Image

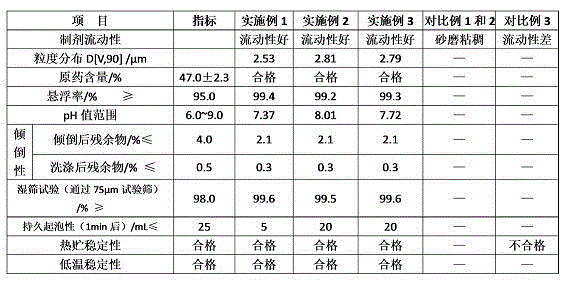

Examples

Embodiment 1600

[0018] Embodiment 1600g / L imidacloprid suspending agent and preparation

[0019] Formula: 97% imidacloprid technical 48.5g, 6g synthetic dispersant JM, 2g penetrant T, 3g4% xanthan gum hydrogel, 1.0g magnesium aluminum silicate, 0.2g defoamer, 3g urea, 36.3g water;

[0020] Preparation process: According to the ratio in the formula, put water, synthetic dispersant JM, penetrant T, magnesium aluminum silicate, and urea into the high-speed shearing kettle in sequence, stir and shear evenly, add imidacloprid original drug and shear evenly, Then suck the material into the sand mill for sand milling until the detected particle size D[V,90] is less than 5 microns, withdraw it into the shear kettle, add 4% xanthan gum hydrogel to shear evenly, and defoamer Add in batches during the process depending on the foaming situation.

Embodiment 2600

[0021] Embodiment 2600g / L imidacloprid suspending agent and preparation

[0022] Formula: 97% imidacloprid technical 48.5g, 4g synthetic dispersant JM, 2.5g sodium dodecylbenzenesulfonate, 2g4% xanthan gum hydrogel, 2.0g magnesium aluminum silicate, 0.2g defoamer, 3g ethyl Glycol, 37.8g water;

[0023] Preparation process: according to the ratio in the formula, put water, synthetic dispersant JM, sodium dodecylbenzenesulfonate, magnesium aluminum silicate, and ethylene glycol into the high-speed shearing kettle in sequence, stir and shear evenly, add The imidacloprid original drug is cut evenly, and then the material is sucked into a sand mill for sand grinding until the detected particle size D[V,90] is less than 5 microns, then withdrawn into the shearing kettle, and added 4% xanthan gum hydrogel to shear Uniformity is enough, and the defoamer is added in batches during the process depending on the foaming situation.

Embodiment 3600

[0024] Embodiment 3600g / L imidacloprid suspending agent and preparation

[0025] Formula: 97% imidacloprid technical 48.5g, 5g synthetic dispersant JM, 0.5g sodium dodecylbenzenesulfonate, 1g penetrant T, 4g4% xanthan gum hydrogel, 0.2g defoamer, 3g urea, 37.8 g water;

[0026] Preparation process: According to the ratio in the formula, put water, synthetic dispersant JM, sodium dodecylbenzenesulfonate, penetrant T, and urea into the high-speed shearing kettle in sequence, stir and shear evenly, and add the original drug of imidacloprid Cut evenly, and then suck the material into the sand mill for sand grinding until the detected particle size D[V,90] is less than 5 microns, then withdraw it into the shear kettle, add 4% xanthan gum hydrogel and cut evenly , The defoamer is added in batches during the process depending on the foaming situation.

[0027] Comparative Test 1600g / L Imidacloprid Suspending Concentrate

[0028] The 2 g of penetrant T in Example 1 was replaced wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com