Vacuum arc-extinguishing chamber, coil-type contact element and current coil

A technology of current coil and contact assembly, which is applied in the direction of high-voltage/high-current switches, circuits, electric switches, etc., can solve the problems of large overall resistance, long conductive path of current coil, uneven distribution of the overall magnetic field, etc., and achieve a small overall circuit , Improve the breaking performance and the effect of uniform magnetic field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

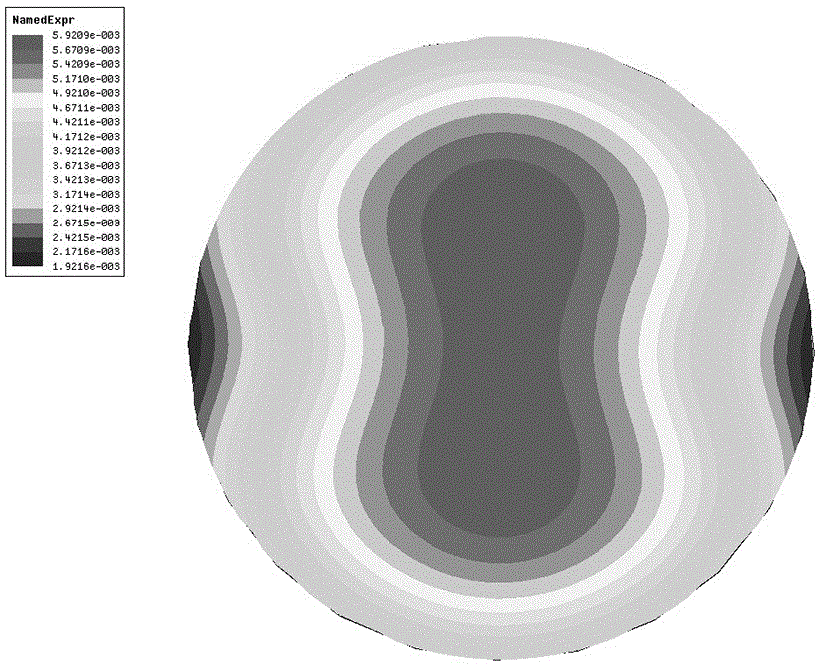

Image

Examples

Embodiment Construction

[0028] Such as figure 1 , figure 2As shown, an embodiment of a current coil for a coiled contact assembly, the current coil in this embodiment includes a first sub-coil 100 and a second sub-coil 200 that extend around the circumferential direction and are arranged in parallel, and each sub-coil includes The upper coil section for conductive connection with the conductive rod of the contact assembly and the lower coil section for conductive connection with the contact blade of the contact assembly that are staggered in the vertical direction and conductively connected in series, the first sub-coil 100 includes The first upper coil segment 101 and the first lower coil segment 102, the second sub-coil 200 includes the second upper coil segment 201 and the second lower coil segment 202, wherein the first upper coil segments 101 of the first sub-coil 100 are arranged at intervals Above the second lower coil segment 202 of the second sub-coil 200, the second upper coil segment 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com