Test and evaluation method for deep hard roof coal seam bump proneness

A hard roof and tendency technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of underestimation and underestimation of coal seam impact tendency, hidden dangers buried in mine safety mining, etc., to achieve the solution of impact tendency error The effects of misjudgment, accurate evaluation results, and ease of promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]The present invention provides a method for testing and evaluating the impact tendency of deep hard roof coal seams. In order to make the purpose, technical scheme and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0049] In order to illustrate the present invention in more detail, more detailed examples are listed below for illustration.

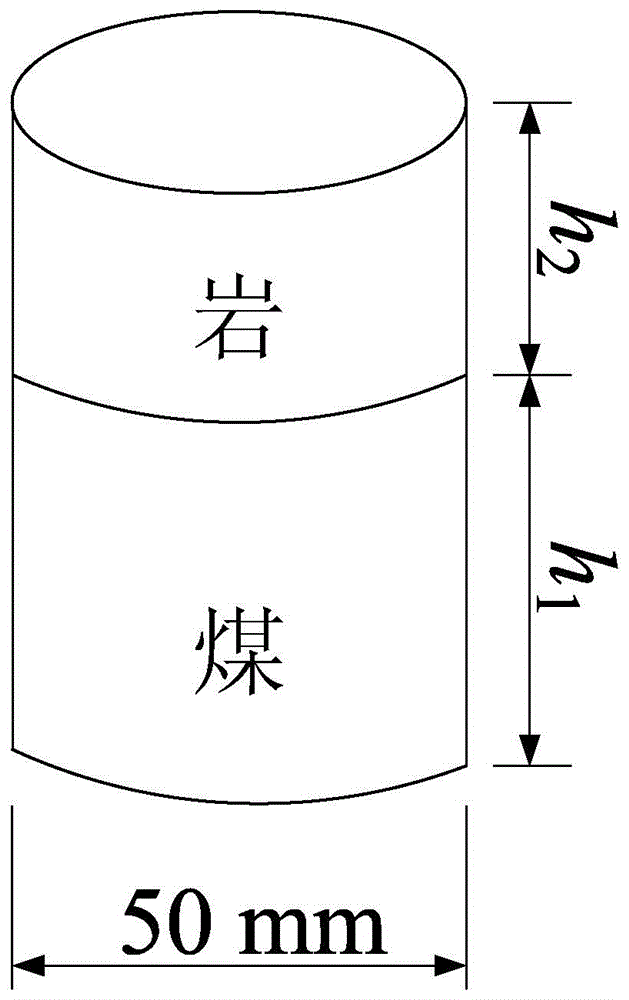

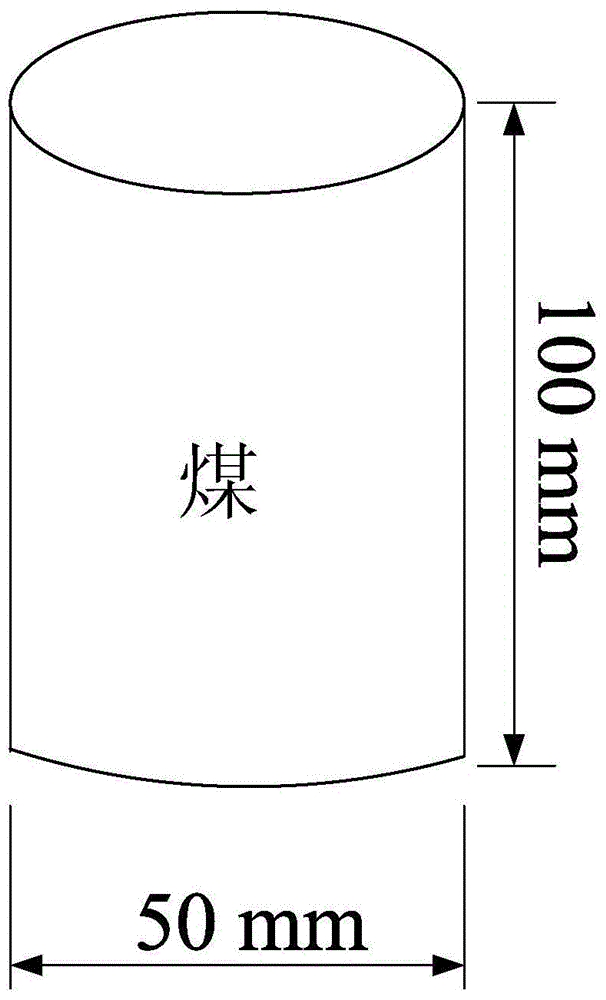

[0050] The depth of the 3# coal seam in a mine is 856-1137m, the development of the coal seam is stable, the structure is simple, the thickness is 5-9m, and the average thickness is H 1 It is 6.8m. The immediate roof above the coal seam is hard and compact siltstone, with a uniaxial compressive strength of about 78.5 MPa and an average thickness of H 2 It is 13.2m.

[0051] Above-mentioned 3# coal seam belongs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com