Electro hydraulic actuator for butterfly valve

A technology of electro-hydraulic actuators and butterfly valves, applied in valve details, valve devices, valve operation/release devices, etc., can solve the problems of increasing system volume and complexity, large load utilization pressure loss, throttling and heating of valve control systems Large and other problems, to achieve the effect of meeting the on-site control function, fast driving response, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

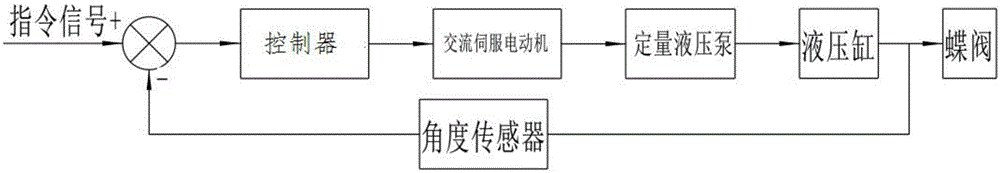

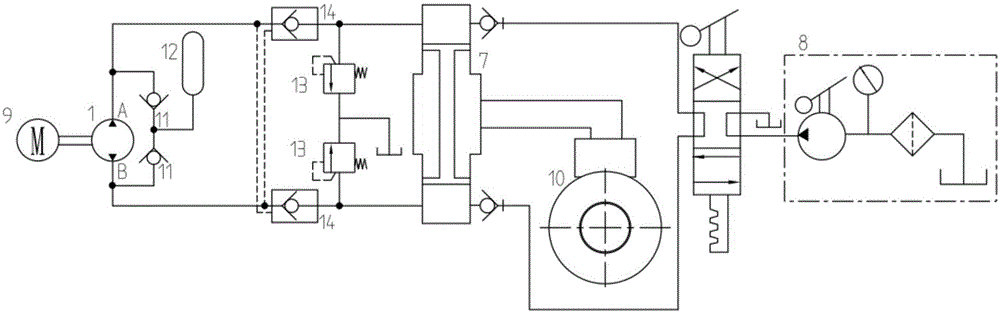

[0030] Such as figure 1 As shown, the electro-hydraulic actuator for the butterfly valve of the present invention includes a housing 2, an electric control part and a hydraulic system. The electric control part includes a controller 5 , a display 4 , a control switch 3 , an angle sensor 6 , the control switch 3 , and the angle sensor 6 are all connected to the controller 5 . The controller 5 can be controlled by operating the control switch 3 . Both the display 4 and the control switch 3 are fixed on the outer surface of one side of the casing 2 . The controller 5 is used to receive the control electric signal, drive the AC servo motor 9 to control the flow rate of the hydraulic circuit to drive the rack and pinion hydraulic cylinder 7 to operate to realize the opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com