Disassembly-free prefabricated concrete thermal-insulation wall formwork

A prefabricated concrete and thermal insulation wall technology, applied in thermal insulation, walls, building components, etc., can solve the problems of unenvironmental protection and large wood usage, and achieve the effects of reducing consumption, shortening time, and reducing fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

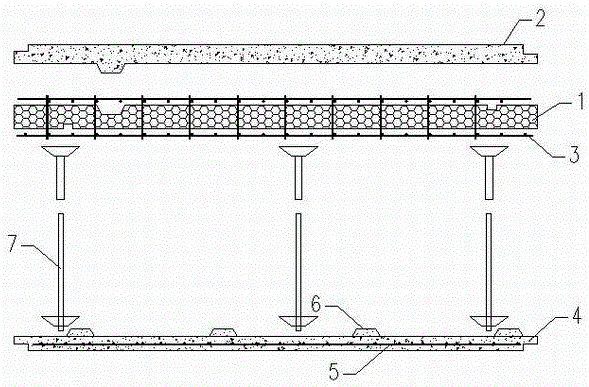

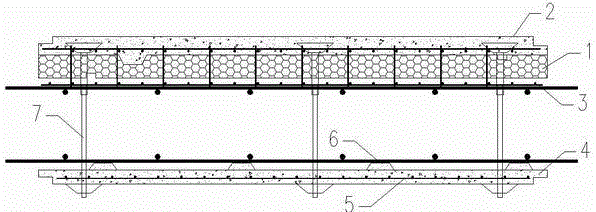

[0027] The following structure is attached figure 1 , 2 , 3, 4 describe the present invention in detail:

[0028] A demolition-free prefabricated concrete thermal insulation wall template, which includes a thermal insulation board body 1, an outer concrete protective layer 2 on the outer side of the thermal insulation board body 1, the thermal insulation board body 1 and the outer concrete protective layer 2 are connected through a steel wire grid 3, three glued together to form a whole;

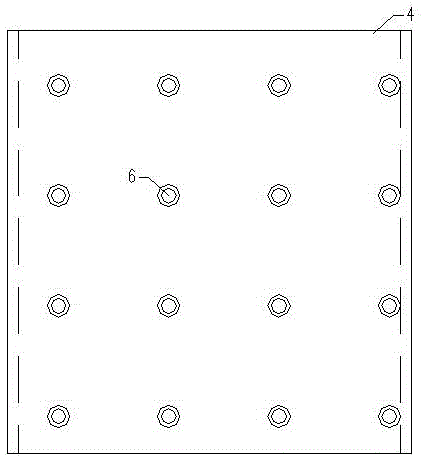

[0029] The other side of the insulation board body 1 is the inner concrete protective layer 4, and the inner concrete protective layer 4 is provided with a steel wire flat mesh 5, and several trapezoidal circular platforms 6 are evenly distributed on one side of the surface;

[0030] The outer concrete protective layer 2 and the inner concrete protective layer 4 are connected as a whole through the pull sleeve screw 7.

[0031] The ends of the outer concrete protection layer 2 and the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com