Process bamboo rhizome, as well as processing method and use thereof

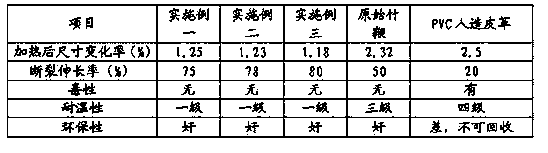

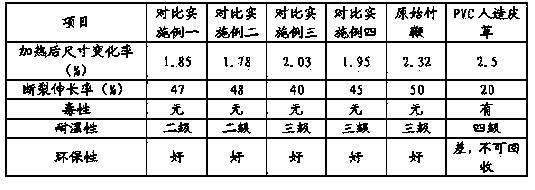

A processing method and technology of bamboo whips, which are applied to wood processing appliances, manufacturing tools, etc., can solve the problems of uneven quality, short service life, easy breakage and deformation of natural bamboo whips, and achieve long service life, beautiful appearance, good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] At the end of the year and in winter in November, cut the bamboo whips with a uniform internode and a diameter of 1.0-2.0cm that grow outside the soil. When harvesting, the length of the bamboo whips is 40-45cm. Trim the roots on the bamboo whip; keep the root length 3-4mm. Put the harvested bamboo whip bundles in a ventilated and dry indoor environment with a temperature of 10-20°C for 60-70 days to dry in the shade; disassemble the dried bamboo whips and arrange them neatly, let the sun dry naturally, and wait for the bamboo whips to dry. The color changes from green to khaki, and it cannot be exposed to rain to produce mildew, and the moisture content is 12-15%; the roots on the khaki-colored bamboo whip nodes are trimmed to keep the root length of 0.9-1.2mm, and the bamboo whip The length sawed is 40-52cm, then the bamboo whip after natural drying is polished for 35-50min; the alkyl acyl quaternary ammonium salt softener, water and hydrogen peroxide are prepared int...

Embodiment 2

[0047] At the end of the year and winter in December, cut the bamboo whips with a uniform internode and a diameter of 1.0-2.0cm that grow outside the soil, and the length of the bamboo whips when harvested is 45-50cm. The bamboo taken from the bamboo whip is high-section bamboo, and then the roots on the bamboo whip nodes are trimmed; the length of the roots is 3-4mm. Put the harvested bamboo whip bundles in a ventilated and dry indoor environment with a temperature of 10-20°C for 70-80 days; disassemble the dried bamboo whips and arrange them neatly, let the sun dry naturally, and wait for the bamboo whips The color changes from green to khaki, and it cannot be exposed to rain to produce mildew, and the moisture content is 9-12%; the roots on the khaki-colored bamboo whip nodes are trimmed to keep the root length of 0.9-1.2mm, and the bamboo whip The length is sawed to be 40-52cm, and then the bamboo whip after natural drying is polished for 50 minutes; water and hydrogen per...

Embodiment 3

[0049] In January of early winter, cut the bamboo whips with a uniform internode and a diameter of 1.0-2.0cm growing outside the soil, and the length of the bamboo whips when harvested is 50-55cm. The bamboo that the bamboo whip is taken from is golden moso bamboo, and then the roots on the bamboo whip joints are trimmed; the length of the roots is 3-4mm. Put the harvested bamboo whip bundles in an indoor environment with a temperature of 10-20°C for 80-90 days; disassemble and arrange the bamboo whips after drying in the shade, let the sun dry naturally, and wait until the color of the bamboo whips changes from green to green. Turn into khaki, can not be exposed to rain to produce mildew, and the moisture content is 8-11%; the roots on the khaki-colored bamboo whip joints are trimmed to keep the root length 1.0-1.1mm, and the length of the bamboo whip is sawed as 48-50cm, put the bamboo whip after natural drying into the water shower polishing machine to polish for 40-45min; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com