A kind of prefabricated T-beam and its method of building continuous beam bridge

A prestressed and prestressed tendon technology, applied in bridge construction, bridges, buildings, etc., can solve problems such as cracks, and achieve the effects of increasing the compressive area, reducing compressive strain, and facilitating transportation and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

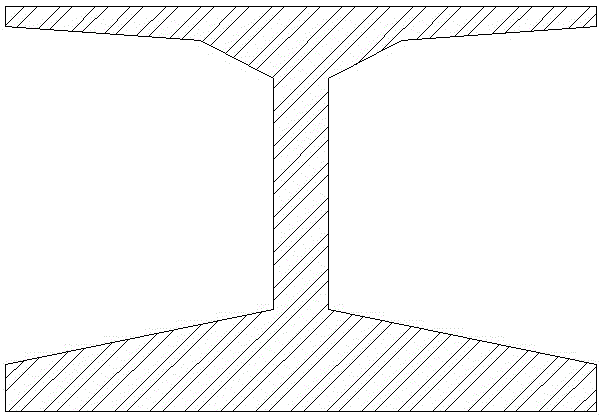

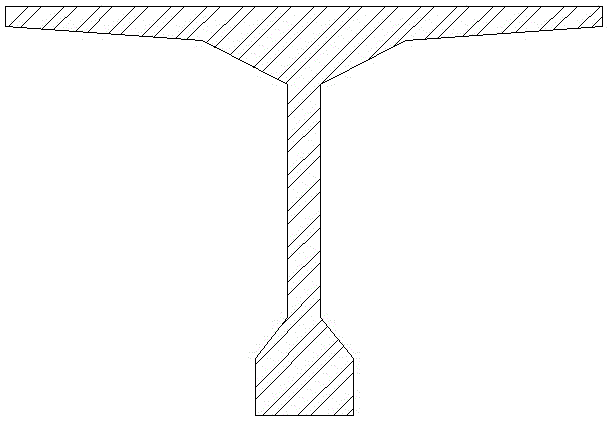

[0016] The first embodiment of the present invention is as figure 1 The prefabricated T-beam shown and the method for constructing continuous beams therefrom. The T-beam is an improved form of a conventional prefabricated T-beam. Within one-eighth of the span at each end, a variable-thickness lower flange 4 is added to the horseshoe 3 under the T-beam web 2 . The thickness of the edge 4 gradually decreases from the end to the mid-span direction. Thus the cross-section of the end is as figure 2 In the I-shape shown, there is a lower flange prestressed tunnel 7 inside the lower flange 4, and the fine-rolled threaded steel bar and the corresponding YGM anchorage are used. There are channels 8 for negative moment tendons in the top plate at the end, flat anchors are used for prestressed tendons, and corresponding tension grooves 6 for negative moment tendons are reserved on the upper surface of the prefabricated beams. On the upper flange, there are protruding steel bars conne...

Embodiment 2

[0028] The second embodiment of the present invention is a modification of the first embodiment, prefabricated T-beams such as Figure 4 shown. There is a longitudinal lower prestressed channel 7 in the lower flange 4, steel strands are used as prestressed tendons, flat anchors are used correspondingly, and corresponding anchoring tooth blocks are provided.

Embodiment 3

[0030] The third embodiment of the present invention is a modification to the first embodiment. The lower flange of the prefabricated T-beam enters the range of the mid-span section in the longitudinal direction. The protruding reinforcement of the edge connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com