Prefabricated T-shaped beam and method of building continuous beam bridge by adopting prefabricated T-shaped beams

A prefabricated and prestressed technology, used in bridge construction, construction, bridges, etc., can solve problems such as cracks, and achieve the effect of increasing the compression area, reducing the compressive strain, and facilitating transportation and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

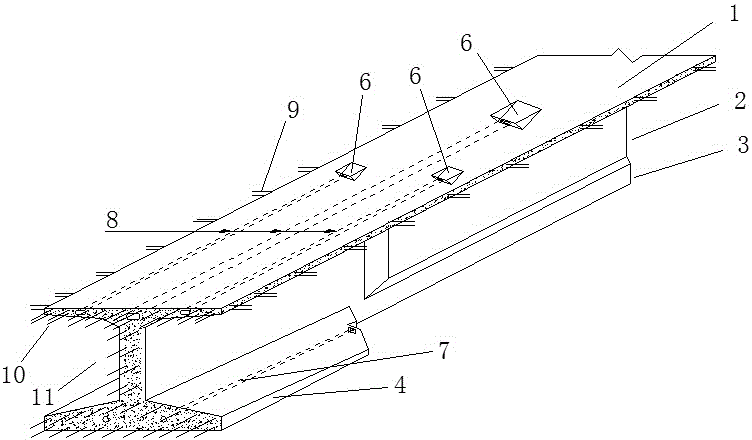

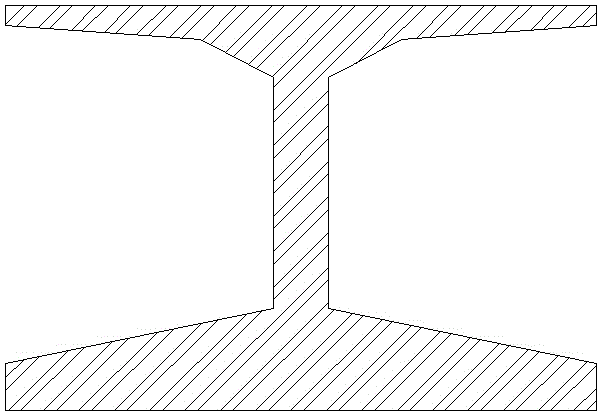

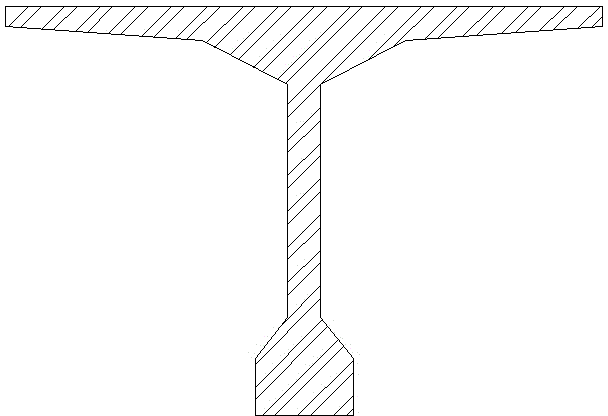

[0015] The first embodiment of the present invention is as figure 1 The prefabricated T-beam shown and the method of using it to construct a continuous beam. The T-beam is an improved form of the conventional prefabricated T-beam. Within one-eighth of the span of each end, a lower flange (4) with variable thickness is added. The thickness of the lower flange (4) is from the end It gradually decreases towards the middle of the span. Thus the cross section of the end is like figure 2 In the I-shape shown, the lower flange (4) has a lower flange pre-stressed channel (7), and it adopts a finish rolled rebar and corresponding YGM anchor. There is a negative moment reinforcement channel (8) in the top plate of the end, the prestressed tendon adopts flat anchors, and the corresponding negative moment reinforcement tension groove (6) is reserved on the upper surface of the precast beam. The upper flange is laterally left with overhanging steel bars connected to the upper flange of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com