Method for preparing functional micro-nano structure dendritic alpha-Fe-based material through iron

A micro-nano structure and functional technology, applied in nanotechnology and other directions, can solve the problems of high cost, high waste iron recycling cost, polluting nano-scale iron process, etc., and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0042]Specific embodiment 1: This embodiment is a method for preparing a functional micro-nano structure dendritic α-Fe-based material from iron, which is prepared as follows:

[0043] 1. Take a set of reaction device:

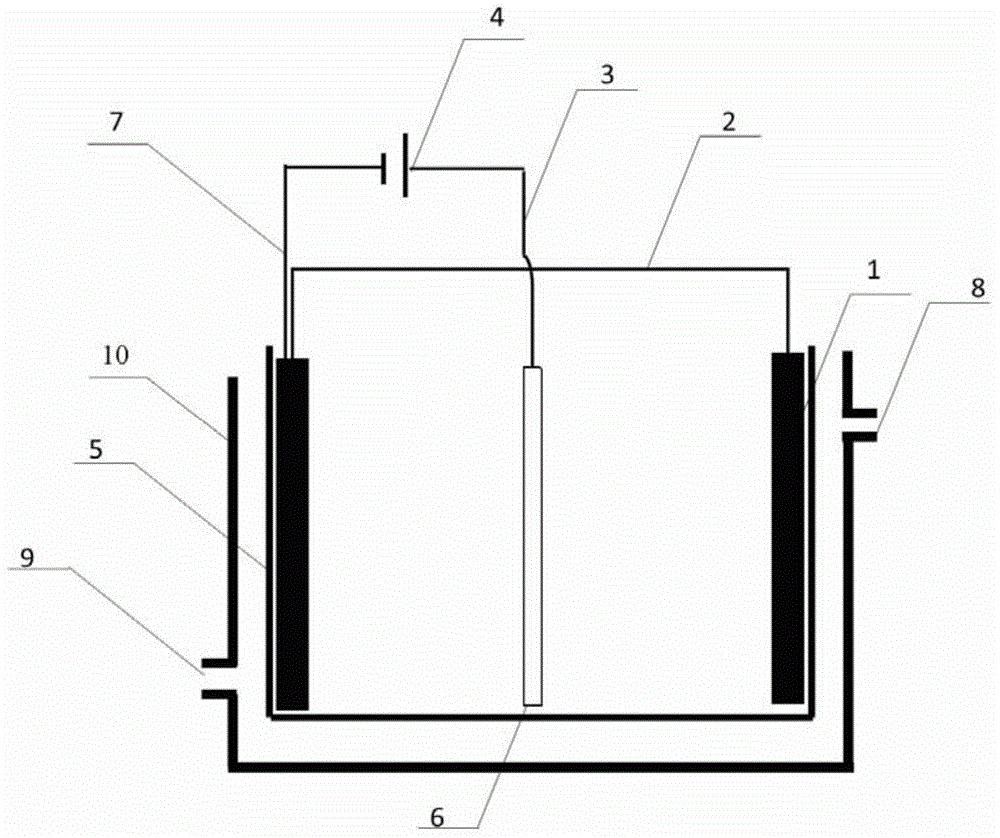

[0044] The reaction device consists of two iron anodes 1, the first wire 2, the second wire 3, a DC power supply 4, an electrolytic tank 5, a copper cathode 6, a third wire 7, a cooling water outlet 8, a cooling water inlet 9 and a cooling tank 10 ;

[0045] The two iron anodes 1 and the copper cathode 6 are all arranged in the electrolytic tank 5, and the copper cathode 6 is arranged in the middle of the two iron anodes 1; the outside of the electrolytic tank 5 is provided with a cooling tank 10, and one side of the cooling tank 10 The lower end is provided with a cooling water inlet 9, and the upper end of the other side of the cooling tank 10 is provided with a cooling water outlet 8; the positive pole of the DC power supply 4 is connected with the copper ...

specific Embodiment approach 2

[0075] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the two iron anodes 1 described in step 1 are pretreated according to the following method: the discarded or used steel is polished to remove the surface rust to obtain steel with a smooth surface; use deionized water to clean the steel with smooth surface for 3 to 5 times, then use a hair dryer to dry it, and then cut it to obtain two iron anodes 1 of the same size. Others are the same as the first embodiment.

specific Embodiment approach 3

[0076] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the iron production rate of the copper cathode 6 in Step 3 is 0.05g / min-0.3g / min. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com