Method for extracting cellulose from sugarcane bagasse

A technology of bagasse and cellulose, applied in the direction of fermentation, etc., can solve the problems of hindering large-scale industrial production, increasing the cost of processing lignocellulosic raw materials, and large demand for glycerin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

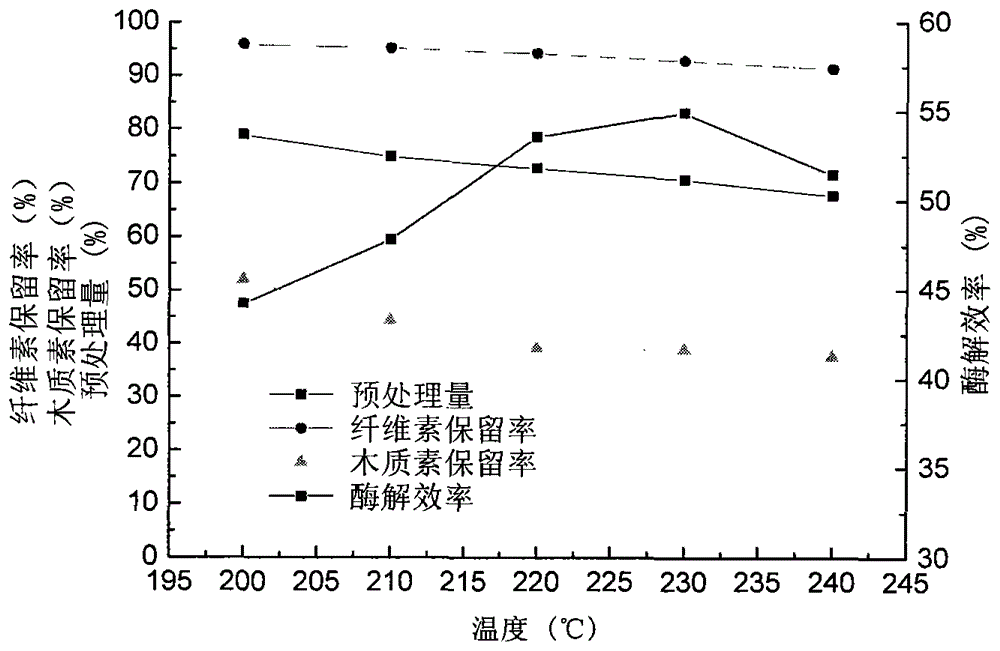

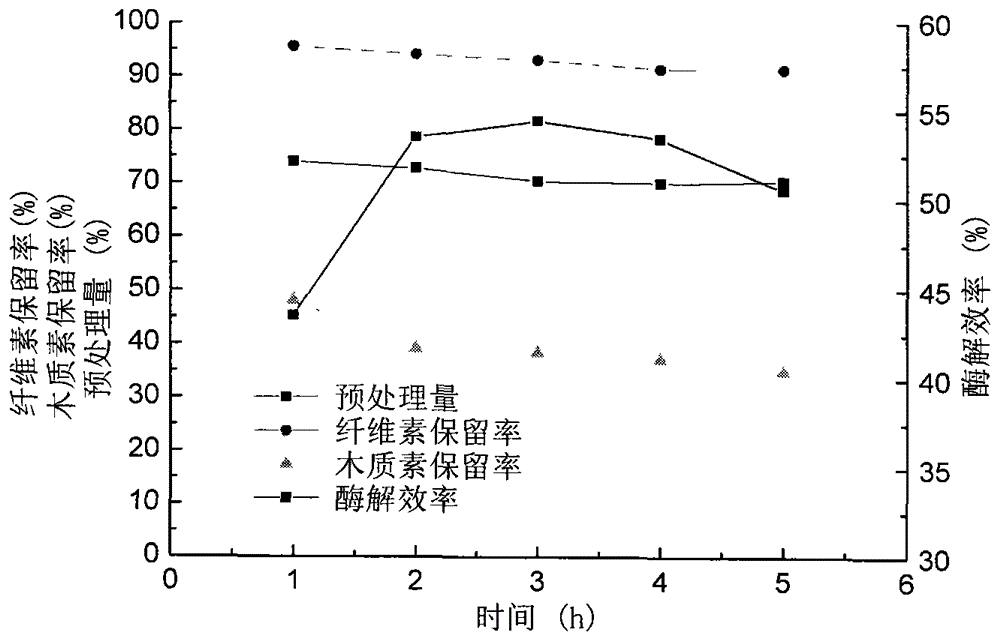

[0028] Example 1: Weigh 10g of bagasse that has passed through a 20-mesh sieve and dried in a 60°C oven to constant weight, and put it into a three-hole flask, add 200g, 70% glycerin aqueous solution, put it into a heating mantle, heat to 220°C, and keep it warm for 2 A temperature probe was placed in the left port of the three-hole flask to control the detection temperature, a mechanical stirring rod was placed in the middle to fully mix the reaction mixture, and a condenser tube was added to the right port to collect condensed water and prevent excessive temperature rise. After the cooking is completed, cool down, and when the temperature drops to about 120°C, slowly add 150g of boiling water, stir rapidly to fully dissolve for about 10min, and start to use G 3 The sand core funnel is suction-filtered, and the temperature is 100 ℃, 500g, 50% glycerin aqueous solution washing, suction-filtration twice, and the temperature is 100 ℃, 400g distilled water washing, suction-filtrat...

example 2

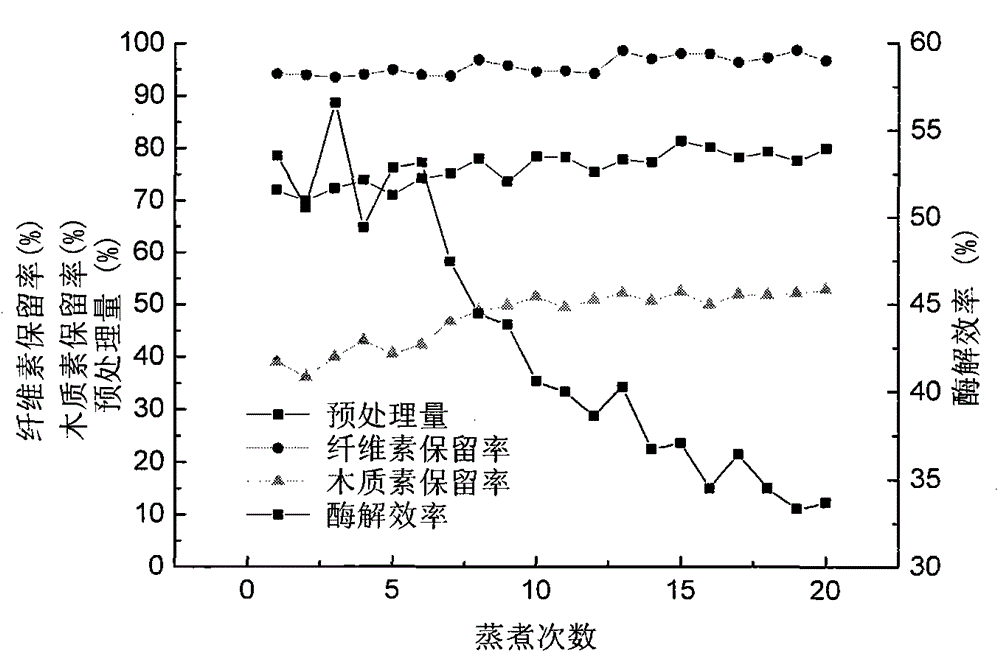

[0029] Example 2: Weigh 10g of bagasse that has passed through a 20-mesh sieve and dried in a 60°C oven to constant weight, and put it into a three-hole flask. Put a temperature probe in the left port of the three-hole flask to control the detection temperature, and put a mechanical stirring rod in the middle. Make the reaction mixture fully mixed, and add a condenser to the right port to collect condensed water and prevent the temperature from rising too high. Set the optimal cooking temperature and time at 220°C for 2 hours. For the 7th time, add 280g of reusable 50% glycerin for washing and suction filtrate to cook, and all the other conditional parameters are the same as example 1. The filter cake obtained is glycerin crude cellulose, and the cellulose component is measured by the NREL method of the American Energy Laboratory. : The cellulose retention rate is 94%, and the lignin retention rate has reached 45%. Take a dry weight of 0.5g wet filter cake and add 25mL, 0.05M,...

example 3

[0030] Example 3: Improve the existing cooking device, add a condenser tube during the cooking process, recover the water evaporated during the heating process and the water obtained by washing with 400g of water and suction filtration, and use it as water for precipitating lignin. According to calculations, about 80% can be recovered- 90% water is used to achieve the purpose of saving water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com