Easy-to-clean polypropylene composite material for see-through electric rice cooker and its preparation method and application

A composite material and easy-to-clean technology, which is applied in the field of modified plastics, can solve the problems that it is difficult for users to check the cooking status of food in the pot, affect the appearance characteristics of the external parts of home appliances, and affect the taste of food by nutrients, and achieve excellent physical and mechanical properties. Excellent transparency, best cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

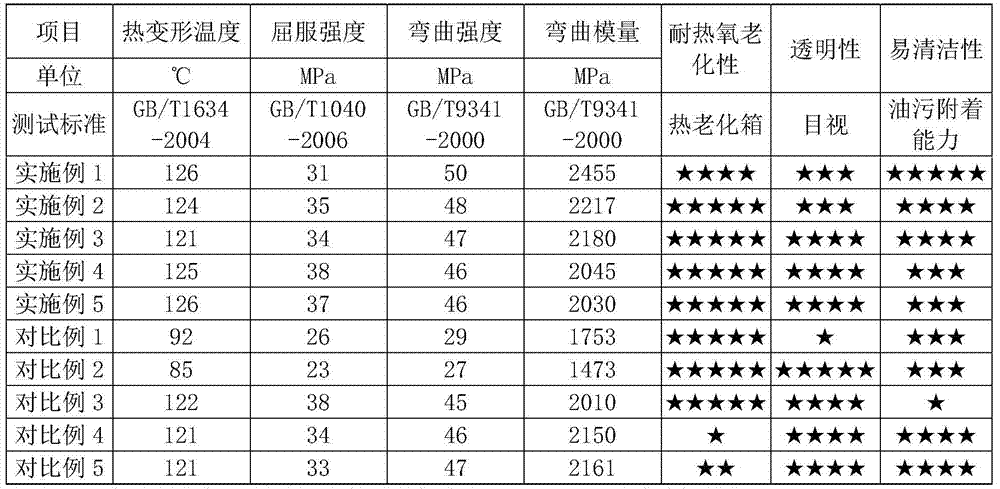

Examples

Embodiment 1

[0053] Proportioning is carried out according to the following mass percentage composition: high crystalline homopolypropylene (brand: PPH-MM20S, China Petroleum & Chemical Corporation Maoming Branch) 30%, transparent filler masterbatch (the used transparent powder grade is: transparent powder T500, Shenzhen Jinhaohui Mining Development Co., Ltd., masterbatch preparation method as above) 20%, polytetrafluoroethylene micropowder (brand: TP200, American 3M company) 8.9%, nano-silica masterbatch (self-made, preparation method as above) 40% %, hindered phenolic antioxidant (model: SONOX 1010, Sanfeng Chemical Co., Ltd., Linyi City, Shandong Province) is 0.2%, phosphorus-containing antioxidant (model: HP-10, Japan Adike Co., Ltd.) is 0.3% , thioester antioxidant (Model: Naugard 412S, American Chemtura Company) is 0.3%, lubricant (calcium stearate 3818, Zhongshan Huamingtai Chemical Co., Ltd.) 0.3%. After weighing the above-mentioned materials, add them into a high-speed mixer (rota...

Embodiment 2

[0056] Proportioning is carried out according to the following mass percentage composition: high crystalline homopolypropylene (brand: PPH-MM20S, China Petroleum & Chemical Corporation Maoming Branch) 60%, transparent filler masterbatch (the used transparent powder grade is: transparent powder T500, Shenzhen Jinhaohui Mining Development Co., Ltd., masterbatch preparation method as above) 14.1%, polytetrafluoroethylene powder (brand: TP200, American 3M company) 10%, nano-silica masterbatch (self-made, preparation method as above) 15% , hindered phenolic antioxidant (model: SONOX1010, Sanfeng Chemical Co., Ltd., Linyi City, Shandong Province) is 0.2%, phosphorus antioxidant (model: SONOX 168, Sanfeng Chemical Co., Ltd., Linyi City, Shandong Province) is 0.2% , thioester antioxidant (Model: Naugard 412S, American Chemtura Company) is 0.2%, lubricant (calcium stearate 3818, Zhongshan Huamingtai Chemical Co., Ltd.) 0.3%.

[0057] After weighing the above-mentioned materials, add th...

Embodiment 3

[0060] Proportioning according to the following mass percentage composition: high crystalline homopolypropylene (brand: PPH8020, Langang Petrochemical Co., Ltd.) 63.8%, transparent filler masterbatch (transparent powder used: transparent powder 1250 mesh, Guangzhou Yongjiu Fine Chemical Co., Ltd., masterbatch preparation method as above) 10%, polytetrafluoroethylene micropowder (brand: TP200, American 3M Company) 5%, nano-silica masterbatch (self-made, preparation method as above) 20%, hindered phenols Antioxidant (Model: 1790, American Cytec Chemical Co., Ltd.) is 0.3%, phosphorus-containing antioxidant (Model: SONOX 626, Linyi Sanfeng Chemical Co., Ltd., Shandong Province) is 0.3%, and thioester antioxidant The agent (model: Naugard 412S, American Chemtura Company) was 0.3%, and the lubricant (zinc stearate BS-2818, Zhongshan Huamingtai Chemical Co., Ltd.) was 0.3%.

[0061] After weighing the above-mentioned materials, add them into a high-speed mixer (rotating speed 1200rp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com