Ethane dehydrogenation method

A technology for ethane and dehydrogenation, applied in chemical instruments and methods, chlorine/hydrogen chloride, hydrocarbons, etc., can solve problems such as separation, poor mass transfer and heat transfer performance, and improve mass transfer and heat transfer performance, production operations , the effect of easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

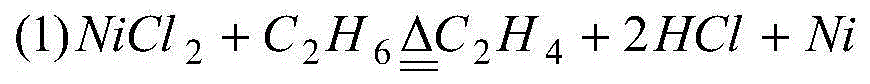

Method used

Image

Examples

Embodiment 1

[0049] (1) NiCl 2 powder suspended on nickel-bismuth alloy melt to obtain NiCl 2 and nickel-bismuth alloy suspension;

[0050] (2) Pass ethane into NiCl 2 In the suspension of nickel-bismuth alloy, the reaction temperature is controlled to be 550°C, and the flow rate of ethane is controlled so that the conversion rate of ethane is 76%. 2 h 4 Mixed gas with HCl, solid NiCl 2 It is reduced to Ni and melted in nickel-bismuth alloy melt;

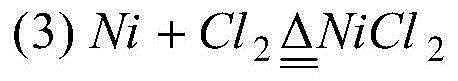

[0051] (3) chlorine gas is passed into step 2) in the nickel-bismuth alloy melt that obtains, and the temperature of control chlorination is 550 ℃, makes Ni and Cl 2 The reaction produces NiCl 2 Suspended on nickel-bismuth alloy, controlled Cl 2 The molar ratio with Ni is 1:1, NiCl 2 continue to react with ethane;

[0052] (4) the obtained step 2) containing C 2 h 4 The mixed gas with HCl absorbs HCl with water to obtain ethylene and hydrochloric acid as a by-product; see Table 1 for the main components of the ethane dehydrogenation t...

Embodiment 2

[0056] (1) NiCl 2 powder suspended on nickel-bismuth alloy melt to obtain NiCl 2 and nickel-bismuth alloy suspension;

[0057] (2) Pass ethane into NiCl 2 In the suspension of nickel-bismuth alloy, the reaction temperature is controlled at 650°C, and the flow rate of ethane is controlled so that the conversion rate of ethane is 86%. 2 h 4 Mixed gas with HCl, solid NiCl 2 It is reduced to Ni and melted in nickel-bismuth alloy melt;

[0058] (3) Chlorine is fed into the nickel-bismuth alloy melt that step 2) obtains, and the temperature of control chlorination is 650 ℃, makes Ni and Cl 2 The reaction produces NiCl 2 Suspended on nickel-bismuth alloy, controlled Cl 2 The molar ratio with Ni is 0.9:1, NiCl 2 continue to react with ethane;

[0059] (4) the obtained step 2) containing C 2 h 4 The mixed gas with HCl absorbs HCl with water to obtain ethylene and hydrochloric acid as a by-product; see Table 2 for the main components of the ethane dehydrogenation tail gas aft...

Embodiment 3

[0063] (1) NiCl 2 powder suspended on nickel-bismuth-lead alloy melt to obtain NiCl 2 and nickel-bismuth-lead alloy suspension;

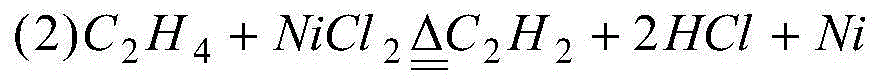

[0064] (2) Pass ethane into NiCl 2 In the suspension of nickel-bismuth-lead alloy, the reaction temperature is controlled at 700°C, and the flow rate of ethane is controlled so that the conversion rate of ethane is 96%. 2 h 4 、C 2 h 2 Mixed gas with HCl, solid NiCl 2 It is reduced to Ni and melted in nickel-bismuth-lead alloy melt;

[0065] (3) chlorine gas is passed into step 2) in the nickel-bismuth-lead alloy melt that obtains, and the temperature of control chlorination is 700 ℃, makes Ni and Cl 2 The reaction produces NiCl 2 Suspended on nickel-bismuth-lead alloy, controlling Cl 2 The molar ratio with Ni is 0.7:1, NiCl 2 continue to react with ethane;

[0066] (4) the obtained step 2) containing C 2 h 4 、C 2 h 2 The mixed gas with HCl absorbs HCl with water to obtain ethylene and acetylene and hydrochloric acid as by-products; se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com