Wet lead wire preparing and drying integrated machine and wet lead wire preparing and drying integrated method

An all-in-one and drying technology, applied in the field of integrated wet manufacturing and drying equipment, can solve the problems of unstable product performance, large drug storage in the workshop, long production cycle, etc., so as to improve the intrinsic safety, save engineering investment and production. Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

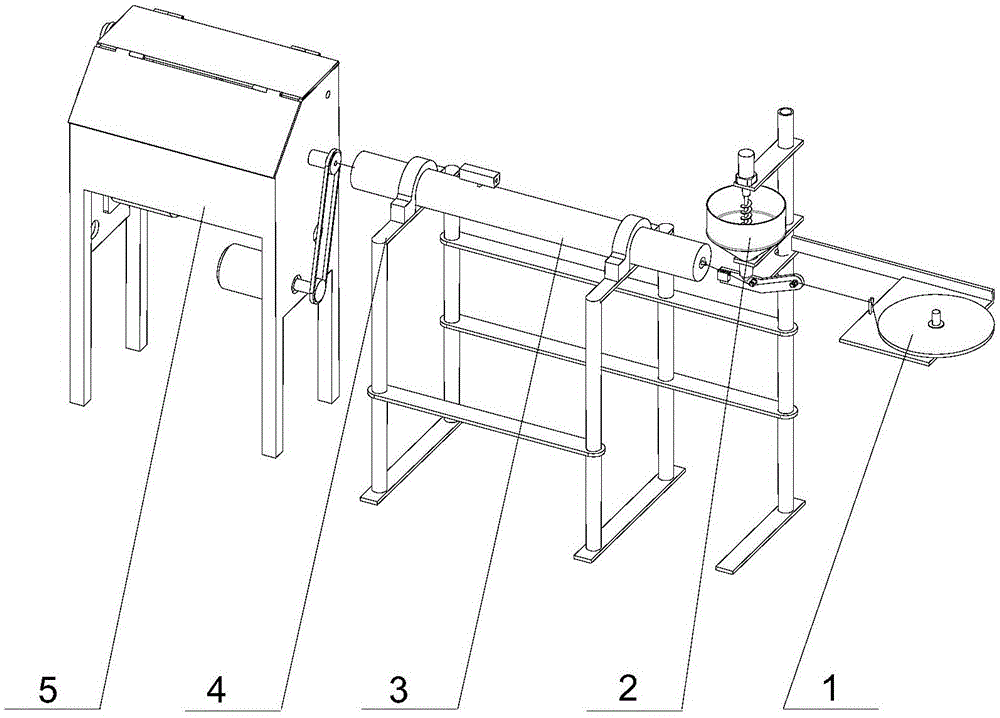

[0018] An integrated method of wet manufacturing, drawing and drying, which is characterized in that: firstly, the lead paper tray 1 is placed on the frame, and then the lead paper is manually passed through the dosing part of the dosing device 2, passes through the drying device 3, and then enters the After rubbing the drawing and taking-up device 5, fix it; secondly, manually add the mixed wet medicine into the medicine hopper in the quantitative dosing device 2; then first let the drying device work, and automatically start the rubbing and taking-up after reaching the set temperature Line device for lead production.

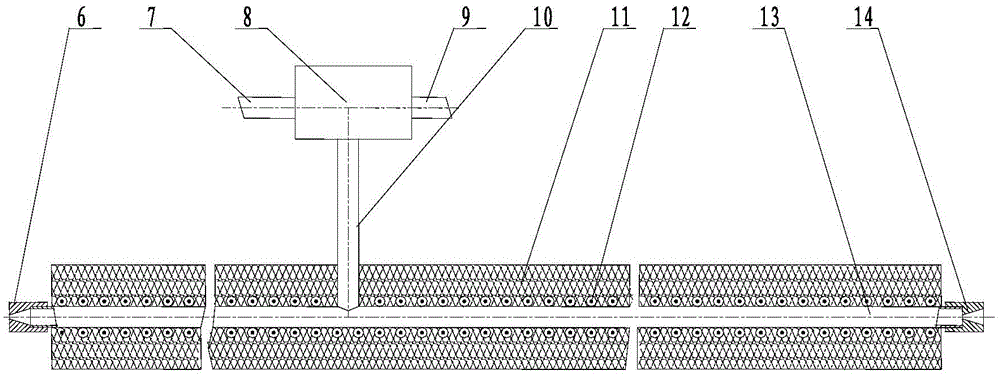

[0019] Such as figure 1 Shown is a wet-process lead-drying integrated machine, which is mainly com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com