A method for strengthening porous ceramic joints

A porous ceramic and joint connection technology, which is applied in the field of porous ceramic joint connection, can solve the problems of low connection strength of porous ceramic joints, achieve the effects of improving connection strength, controllable metal content, and improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

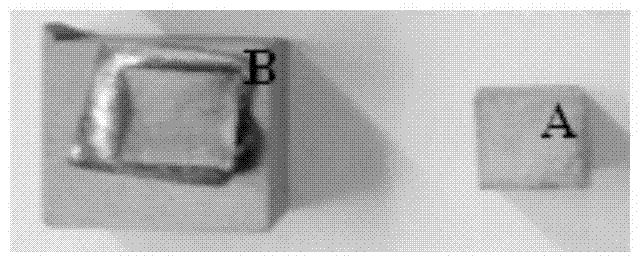

[0025] Specific implementation method: This embodiment is a method for strengthening the connection of porous ceramic joints, which is specifically completed according to the following steps:

[0026] 1. Preparation of silver nitrate aqueous solution: Dissolve silver nitrate in deionized water to obtain silver nitrate aqueous solution with a concentration of 0.1g / mL~2.5g / mL;

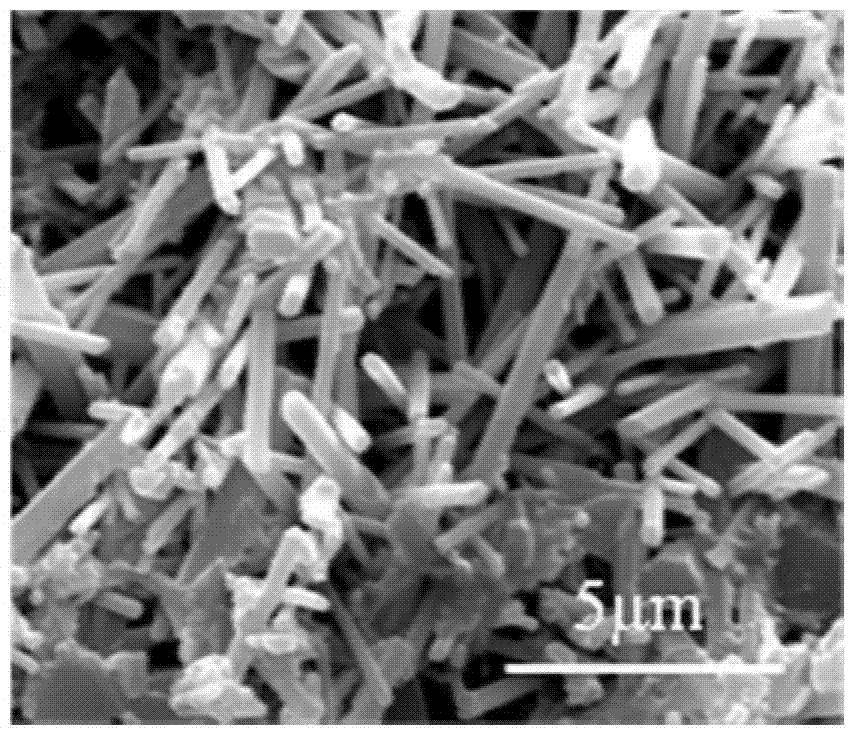

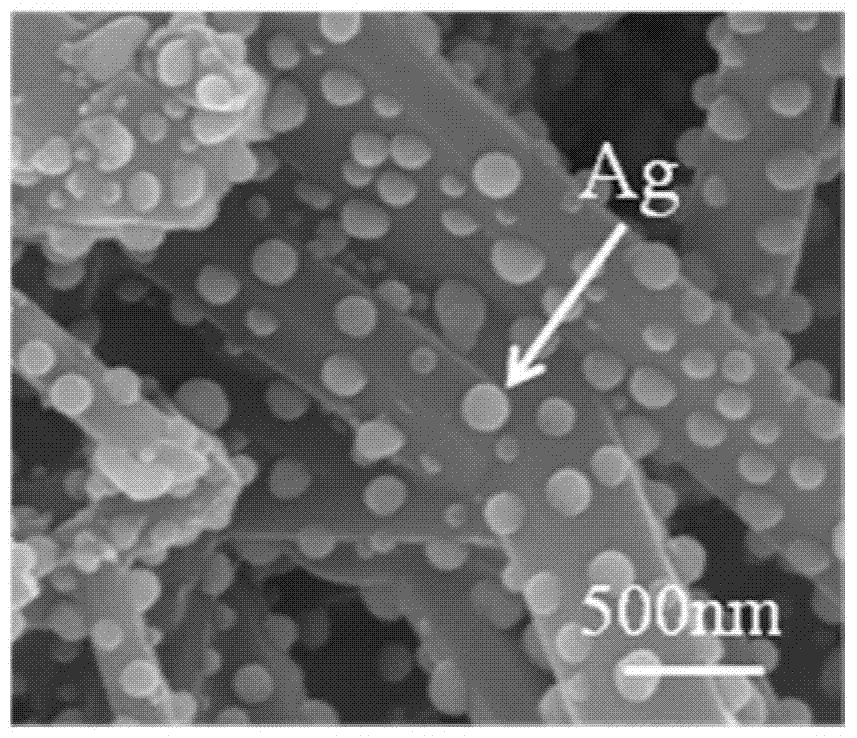

[0027] 2. Ultrasonic impregnation: First, ultrasonically clean the porous ceramics, and then immerse the porous ceramics in silver nitrate aqueous solution with a concentration of 0.1g / mL-2.5g / mL for ultrasonic impregnation. The ultrasonic impregnation time is 1min-10min. Finally, put it into an oven, and dry it at an oven temperature of 40-120°C for 1h-24h to obtain impregnated and dried porous ceramics;

[0028] 3. Vacuum sintering: place the impregnated and dried porous ceramics in a vacuum sintering furnace, and evacuate the vacuum sintering furnace to a vacuum degree of 7.0×10 -2 Pa~1.5×10 -2 Pa, ...

specific Embodiment approach 2

[0033]Embodiment 2: The difference between this embodiment and Embodiment 1 is that the porous ceramics described in step 2 are ceramics with a porosity of 5% to 90%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the porous ceramic described in step two is Si 3 N 4 Ceramics, SiAlON ceramics, Si 2 N 2 O ceramics, AlN ceramics, TiN ceramics, SiC ceramics, SiBCN ceramics, BN ceramics, ZrO 2 Ceramic, Al 2 o 3 Ceramic, TiB 2 Ceramic, B 4 Cceramics, ZrB 2 Ceramic, TaB 2 Ceramics, ZrC Ceramics, MoSi 2 Ceramics, MAX phase ceramics or fused silica ceramics; or porous ceramics are composite ceramics, and the composite ceramics are made of Si 3 N 4 Ceramics, SiAlON ceramics, Si 2 N 2 O ceramics, AlN ceramics, TiN ceramics, SiC ceramics, SiBCN ceramics, BN ceramics, ZrO 2 Ceramic, Al 2 o 3 Ceramic, TiB 2 Ceramic, B 4 Cceramics, ZrB 2 Ceramic, TaB 2 Ceramics, ZrC Ceramics, MoSi 2 Two or more of ceramics, MAX phase ceramics and fused silica ceramics are composited; or porous ceramics are reinforced and toughened composite ceramic materials, and the reinforced and toughe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com