Multi-layer oil-water separator and working method therefor

An oil-water separator and layer separation technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of complex separation process, large floor space, high operating intensity, and achieve high integration, extended life, The effect of a compact body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

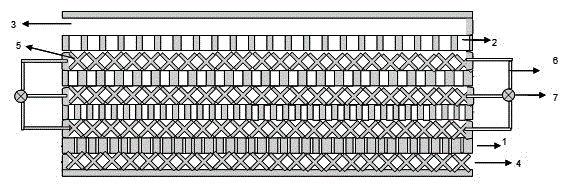

[0037] Use polypropylene filter as the first layer of separation material with a separation pore size of 70-100 μm, polyester non-woven fabric as the second layer of separation material with a separation pore size of 5-10 μm, and polypropylene microporous membrane as the third layer The separation material has a separation pore size of 0.1-0.5 μm, and the polysulfone ultrafiltration membrane is used as the fourth separation material with a separation pore size of 0.01-0.05 μm. Each layer of separation material is separated by a polyester grid with a thickness of 5 mm, and the grid is encapsulated with epoxy resin, and PVC pipelines are embedded in the epoxy resin, and the pipelines of each layer are connected to the four-channel valve On, the cleaning sequence is controlled by adjusting the valve. The whole separation device is a flat plate frame type.

[0038] The oil content in the influent water is 1000mg / L, the oil removal operation is carried out at 0.2MPa, and the flux ...

Embodiment 2

[0042] Use polypropylene filter as the first layer of separation material with a separation pore size of 60-80 μm, use polypropylene non-woven fabric as the second layer of separation material with a separation pore size of 5-10 μm, and use polyvinylidene fluoride microporous filter membrane as the second layer The three-pole separation material has a separation pore size of 0.1-0.5 μm, and the polyethersulfone ultrafiltration membrane is used as the fourth separation material with a separation pore size of 0.02-0.1 μm. Each layer of separation material is separated by a polyester grid with a thickness of 5 mm, and the grid is encapsulated with epoxy resin, and PVC pipelines are embedded in the epoxy resin, and the pipelines of each layer are connected to the four-channel valve On, the cleaning sequence is controlled by adjusting the valve. The entire separation device is a roll separator, the first layer of separation material is aligned with the central tube, and the water i...

Embodiment 3

[0047] Use polypropylene filter as the first layer of separation material with a separation pore size of 60-80 μm, use polypropylene non-woven fabric as the second layer of separation material with a separation pore size of 3-5 μm, and use polyvinylidene fluoride microporous filter membrane as the second layer The three-pole separation material has a separation pore size of 0.1-0.5 μm, and the polyethersulfone ultrafiltration membrane is used as the fourth separation material with a separation pore size of 0.02-0.08 μm. Each layer of separation material is separated by a polyester grid with a thickness of 5 mm, and the grid is encapsulated with epoxy resin, and PVC pipelines are embedded in the epoxy resin, and the pipelines of each layer are connected to the four-channel valve On, the cleaning sequence is controlled by adjusting the valve. The entire separation device is a roll separator, the first layer of separation material is opposite to the membrane shell, and the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Separation aperture | aaaaa | aaaaa |

| Separation aperture | aaaaa | aaaaa |

| Separation aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com