Light and efficient diamond grinding wheel

A technology of diamond and diamond cutter head, which is applied in the field of light-weight and high-efficiency diamond grinding wheels, which can solve the problems of diamond grinding wheels such as their own weight, time-consuming and energy-consuming use, and high production costs, so as to reduce production costs, reduce post-procedure procedures, and ensure service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

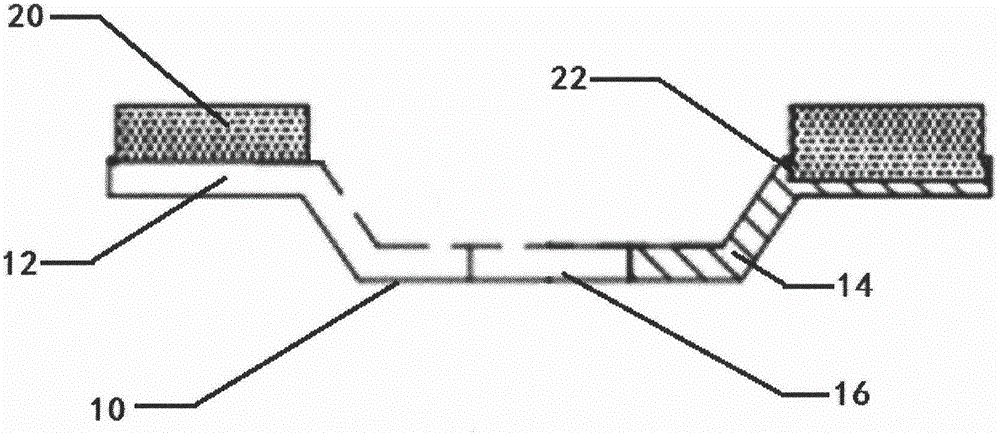

Image

Examples

preparation example Construction

[0021] The preparation method of light weight high-efficiency diamond grinding wheel of the present invention is as follows:

[0022] 1. Mixing: Weigh CuSn alloy powder, FeCoCu alloy powder, Co powder, and diamond according to the ratio and pour them into the mixer for 4 hours to ensure uniform mixing without color difference; among them, the diamond is used with a strength of 25-35 kg , a particle size of 35 / 40, and / or 45 / 50 in a concentration of 20-50%.

[0023] 2. Cutter head sintering: Select the required graphite mold and put it into the sintered iron mold frame. After the graphite mold is assembled as required, add a baffle on the outside, tighten the mold with a wrench, and mix it evenly with a balance with an accuracy of 0.1g. Weigh the metal powder according to the calculated weight and put it into the stone black mold, add the pressure head, tighten it with a wrench, put the assembled graphite mold into a hot press with a power of 80kw for sintering, keep it warm for...

Embodiment 1

[0029] This embodiment relates to a Φ125 lightweight and high-efficiency diamond grinding wheel, which is prepared by the following process:

[0030] (1) prepare mixed powder: choose metal powder by following percentage by weight: CuSn alloy powder 35wt%, FeCoCu alloy powder 40wt%, Co powder 25wt%; Diamond strength 30 kilograms, particle size is 35 / 40, and concentration is 25%, proportioning Then pour it into the mixer and mix it for 4 hours;

[0031] (2) Cutter head sintering: select the cutter head graphite mold, put it into the iron sintering mold frame after assembly, add graphite baffle on the outside, tighten it with a wrench, weigh 21.8 grams of mixed powder with a balance with an accuracy of 0.1 grams, and pour it into In the graphite mold, tighten the mold with a wrench after adding the graphite indenter, put the assembled graphite mold into a hot pressing sintering machine with a power of 80KW, heat to 800°C, and press 250Kg / cm 2 , keep warm for 3 minutes, cool down...

Embodiment 2

[0035] This embodiment relates to a Φ115 lightweight and high-efficiency diamond grinding wheel, which is prepared by the following process:

[0036] (1) prepare mixed powder: choose metal powder by following percentage by weight: CuSn alloy powder 40wt%, FeCoCu alloy powder 45wt%, Co powder 15wt%; Diamond strength 35 kilograms, particle size is 35 / 40, and concentration is 25%, proportioning Then pour it into the mixer and mix it for 4 hours;

[0037] (2) Cutter head sintering: select the cutter head graphite mold, put it into the iron sintering mold frame after assembly, add graphite baffle on the outside, tighten it with a wrench, weigh 21.5 grams of mixed powder with a balance with an accuracy of 0.1 grams, and pour it into In the graphite mold, tighten the mold with a wrench after adding the graphite indenter, put the assembled graphite mold into a hot pressing sintering machine with a power of 80KW, heat to 780°C, and press 250Kg / cm 2 , keep warm for 3 minutes, cool down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com