Manufacturing method for R-Fe-N permanent magnet material granules

A permanent magnetic material, r-fe-n technology, applied in the field of preparation of R-Fe-N permanent magnetic material particles, can solve the problems of difficult to remove, easy to decompose, difficult surfactants, etc., to expand the practical application field, Effect of suppressing the degree of amorphization and reducing the oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

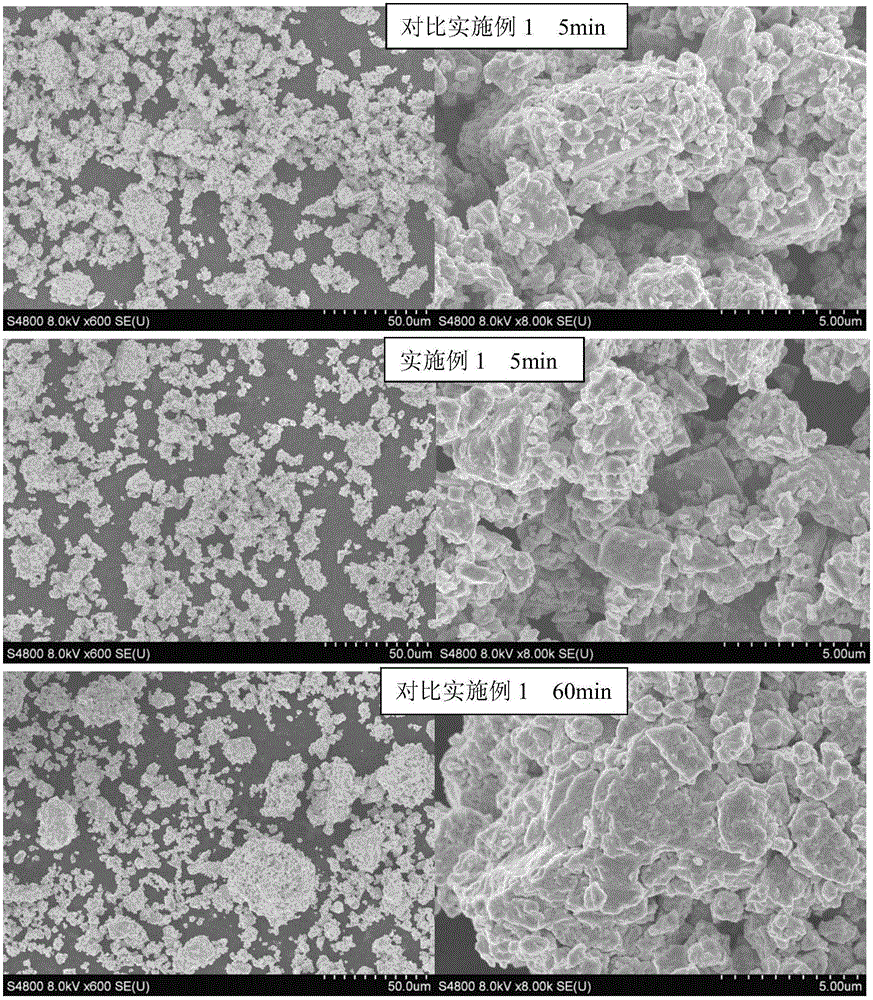

Embodiment 1

[0038] In this embodiment, the raw materials used, the grinding balls and the ratio of the material to the ball are exactly the same as those of Comparative Example 1, the difference is that the present embodiment is different for Sm 2 Fe 17 N x Powder raw materials are subjected to low-temperature dry grinding treatment, the process is as follows:

[0039] (1) The above Sm 2 Fe 17 N x Put the powder raw material into a stainless steel ball mill tank, add stainless steel grinding balls with a diameter of 6.5 mm and 9.5 mm, and the ball-to-material ratio is 10:1. Seal the ball mill tank with raw materials and balls in a glove box, and the protective gas is high-purity Ar gas;

[0040] (2) Place the ball mill tank in liquid nitrogen for low temperature treatment, and take it out after the temperature of the ball mill tank is kept below -150°C;

[0041] (3) Install the ball mill jar on the ball mill and ball mill for 3 minutes under normal temperature environment;

[0042]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com