Forming method of bent/torsional component based on BIM technology

A technology of bending and torsion components and forming method, applied in the field of construction, can solve problems such as high control requirements, assembly errors, inapplicability, etc., and achieve the effects of reducing manufacturing costs, improving top bending accuracy, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

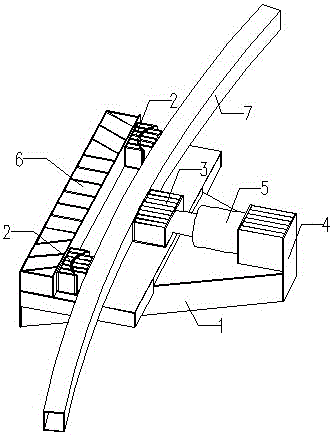

[0030] The present invention will be further described below in conjunction with accompanying drawing.

[0031] Building Information Modeling (Building Information Modeling, referred to as BIM) is a new tool for architecture, engineering, and civil engineering. It is used to describe those computer-aided designs that are mainly based on three-dimensional graphics, object-oriented, and related to architecture. The bending and torsion component forming method of the present invention is designed based on BIM technology, and its specific forming steps are as follows,

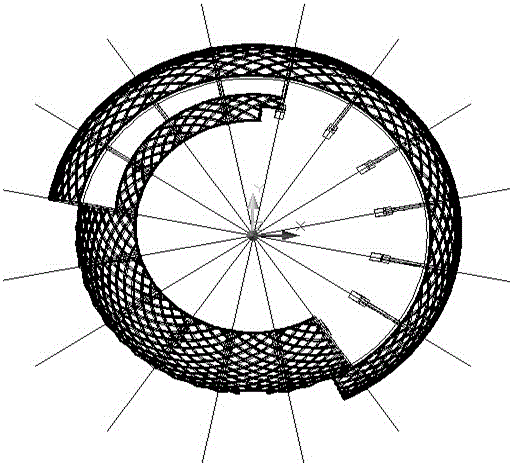

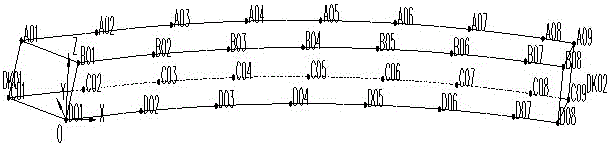

[0032] (1) Establish the BIM model after bending and torsion of the torsion member, import the BIM model into the steel structure-spatial structure design software 3D3S, and use the central point of the building venue where the torsion member is applied ±0.000 elevation as the measurement control point to establish a world coordinate system to generate The absolute coordinates of the bending and torsion members r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com