Black garlic production technology

A production process and technology for black garlic, applied in the field of black garlic, can solve the problems of long fermentation time and short fermentation time of black garlic, and achieve the effects of good taste, short fermentation time and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

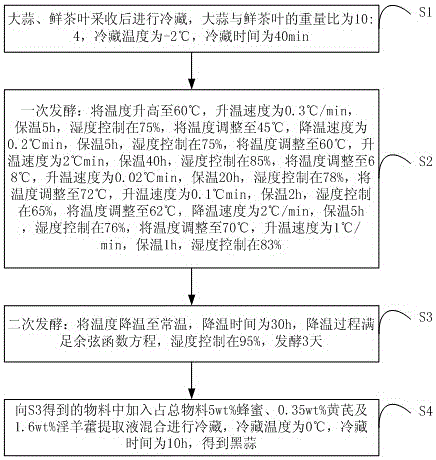

[0023] refer to figure 1 , a kind of manufacture craft of black garlic, comprises the steps:

[0024] S1. Garlic and fresh tea leaves are harvested and refrigerated, the weight ratio of garlic to fresh tea leaves is 10:4, the refrigerated temperature is -2°C, and the refrigerated time is 40 minutes;

[0025] S2. Primary fermentation: raise the temperature to 60°C, the heating rate is 0.3°C / min, keep it warm for 5 hours, control the humidity at 75%, adjust the temperature to 45°C, the cooling rate is 0.2°C / min, keep it warm for 5 hours, and control the humidity At 75%, adjust the temperature to 60°C, the heating rate is 2°C / min, keep warm for 40 hours, control the humidity at 85%, adjust the temperature to 68°C, the heating rate is 0.02°C / min, keep warm for 20h, and control the humidity at 78 %, adjust the temperature to 72°C, the heating rate is 0.1°C / min, keep warm for 2 hours, control the humidity at 65%, adjust the temperature to 62°C, cool down at 2°C / min, keep warm for 5...

Embodiment 2

[0029] A kind of preparation technology of black garlic, comprises the steps:

[0030] S1. Garlic and fresh tea leaves are harvested and refrigerated. The weight ratio of garlic to fresh tea leaves is 10:3.4, the refrigerated temperature is -5°C, and the refrigerated time is 20 minutes;

[0031] S2. Primary fermentation: raise the temperature to 70°C, the heating rate is 0.1°C / min, keep warm for 15 hours, control the humidity at 60%, adjust the temperature to 55°C, cool down at a rate of 0.1°C / min, keep warm for 15 hours, and control the humidity At 60%, adjust the temperature to 67°C, the heating rate is 1°C / min, keep warm for 50h, and control the humidity at 80%, adjust the temperature to 70°C, the heating rate is 0.01°C / min, keep warm for 30h, and control the humidity at 75% %, adjust the temperature to 80°C, the heating rate is 0.05°C / min, keep warm for 4 hours, control the humidity at 60%, adjust the temperature to 65°C, cool down at 1°C / min, keep warm for 20h, and contro...

Embodiment 3

[0035] A kind of preparation technology of black garlic, comprises the steps:

[0036] S1. Garlic and fresh tea leaves are harvested and refrigerated. The weight ratio of garlic to fresh tea leaves is 10:3, the refrigerated temperature is -3°C, and the refrigerated time is 34 minutes;

[0037] S2. Primary fermentation: raise the temperature to 64°C, the heating rate is 0.25°C / min, keep warm for 10 hours, control the humidity at 70%, adjust the temperature to 50°C, cool down at a rate of 0.19°C / min, keep warm for 10 hours, and control the humidity At 72%, adjust the temperature to 62°C, the heating rate is 1.7°C / min, keep warm for 42h, and control the humidity at 84%, adjust the temperature to 69°C, the heating rate is 0.016°C / min, keep warm for 24h, and control the humidity at 77% %, adjust the temperature to 75°C, the heating rate is 0.08°C / min, keep warm for 3 hours, control the humidity at 64%, adjust the temperature to 63°C, cool down at 1.6°C / min, keep warm for 10 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com