Carbon-silicon composite lithium ion battery cathode material and preparation method thereof

A lithium-ion battery, carbon-silicon composite technology, applied in battery electrodes, circuits, electrical components, etc., to achieve the effects of environmental friendliness, long service life, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

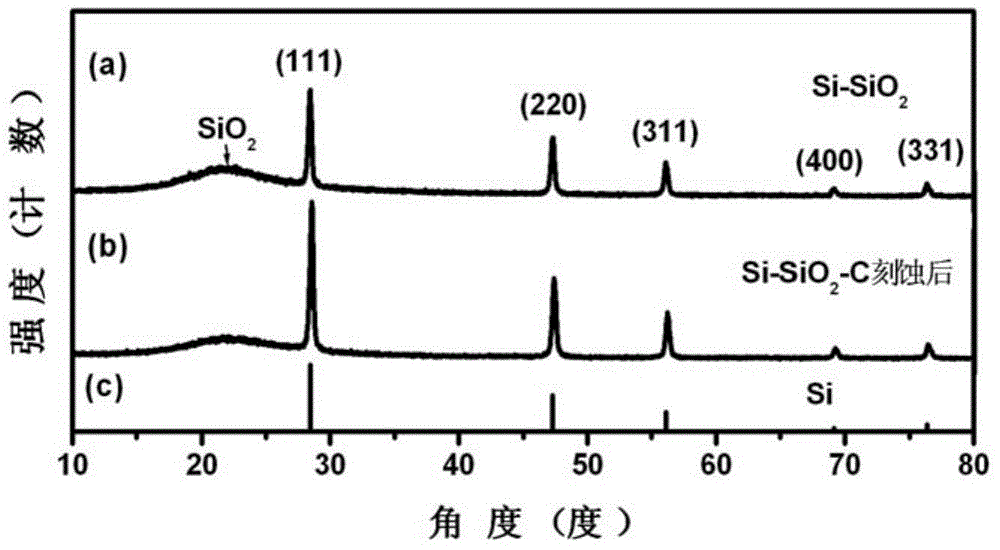

[0027] Si / SiO of the present invention 2 Preparation of / C semi-hollow composite structure

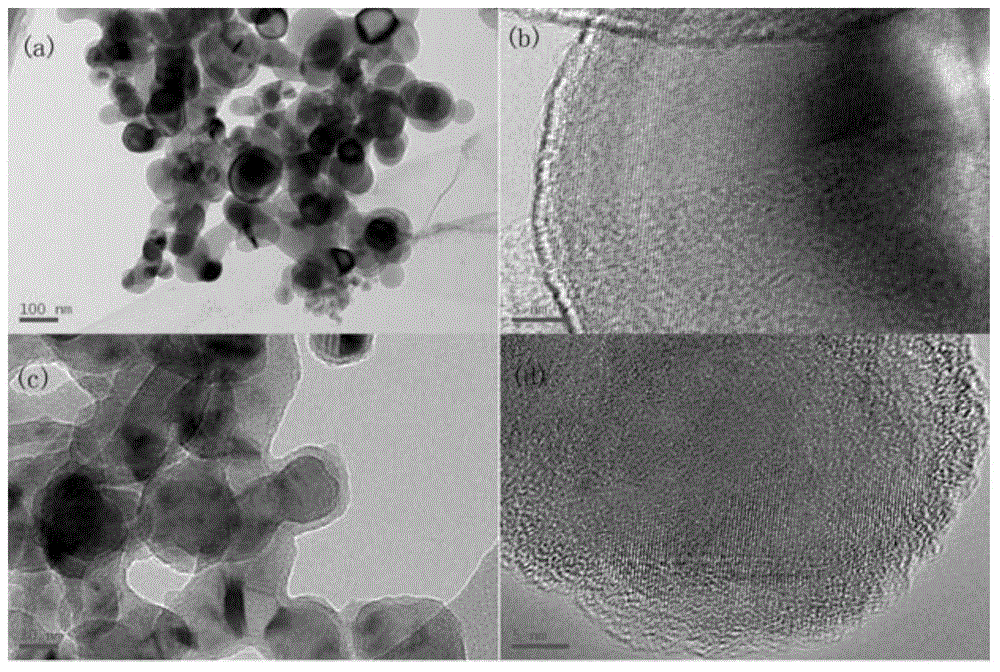

[0028] Add commercial Si to the mixed solution of ammonia water, deionized water and absolute ethanol with a volume ratio of 1:5:50, and add PVP (polyvinylpyrrolidone) with Si mass 1 / 10 for 10 minutes, and then add the volume of deionized water 5:1 ratio of TEOS (tetraethyl silicate). Stir for 1 h, wash with deionized water and absolute ethanol three times by centrifugation, and then dry in a drying oven at 60 ° C to obtain Si / SiO 2 composite structure product, figure 2 (c), (d) is the Si / SiO prepared by this embodiment 2 Sample transmission electron micrographs and high magnification transmission electron micrographs. Si / SiO 2 After the sample was mixed with PVDF (polyvinylidene fluoride) at a mass ratio of 10:1, NMP 20 times the mass of PVDF (N-methylpyrrolidone) was added, stirred, and then carbonized at 850 °C for 2 h under Ar atmosphere. Put the obtained product into 0.5Mol...

Embodiment 2

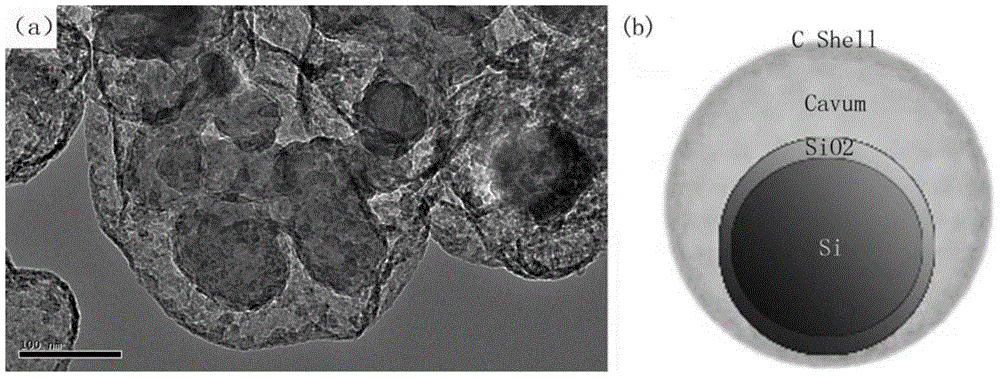

[0030] Add commercial Si to the mixed solution of ammonia water, deionized water and absolute ethanol with a volume ratio of 1:3.18:23.56, and add PVP with Si mass 1 / 5 for ultrasonication for 10 minutes, and then add deionized water with a volume ratio of 2:1 TEOS. Stir for 1 h, wash with deionized water and absolute ethanol three times by centrifugation, and then dry in a drying oven at 60 ° C to obtain Si / SiO 2 Composite structure product, the Si / SiO 2 After the sample was mixed with PVDF with a mass ratio of 6:1, NMP 20 times the mass of PVDF was added, stirred, and then carbonized at 650 °C for 2 h under Ar atmosphere. Put the obtained product into 0.5Mol / L HF and etch it for 1h, wash it with deionized water and absolute ethanol for five times, and dry it at 60°C. The obtained product is Si / SiO 2 / C semi-hollow composite structure. Si accounted for Si / SiO 2 The mass percent range of the / C part hollow composite structure is 63%. image 3 (a) Si / SiO prepared for this e...

Embodiment 3

[0032] Add commercial Si to ammonia water, put it into a mixed solution of deionized water and absolute ethanol with a volume ratio of 3:10:50, add PVP with Si mass 1 / 5 for ultrasonication for 10 minutes, and then add deionized water with a volume ratio of 1:1 TEOS. Stir for 1 h, wash with deionized water and absolute ethanol three times by centrifugation, and then dry in a drying oven at 60 ° C to obtain Si / SiO 2 Composite structure product, the Si / SiO 2 After the sample was mixed with PVDF with a mass ratio of 4:1, NMP with 10 times the mass of PVDF was added, stirred, and then carbonized at 700 °C for 2 h under Ar atmosphere. Put the obtained product into 0.5Mol / L HF and etch it for 1h, wash it with deionized water and absolute ethanol for five times, and dry it at 60°C. The obtained product is Si / SiO 2 / C semi-hollow composite structure. Si accounted for Si / SiO 2 The mass percent range of the / C part hollow composite structure is 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com