Preparation method and preparation device for CIGS-based thin-film solar cell

A technology for solar cells and preparation devices, which is applied in the manufacture of circuits, electrical components, and final products, etc., can solve the problems of uneven composition of the film layer, affect the performance of the light absorbing layer, and reduce the performance of thin-film solar cells, and improve the composition of the solar cell. Uniformity, reduced production cost, simple effect of preparation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

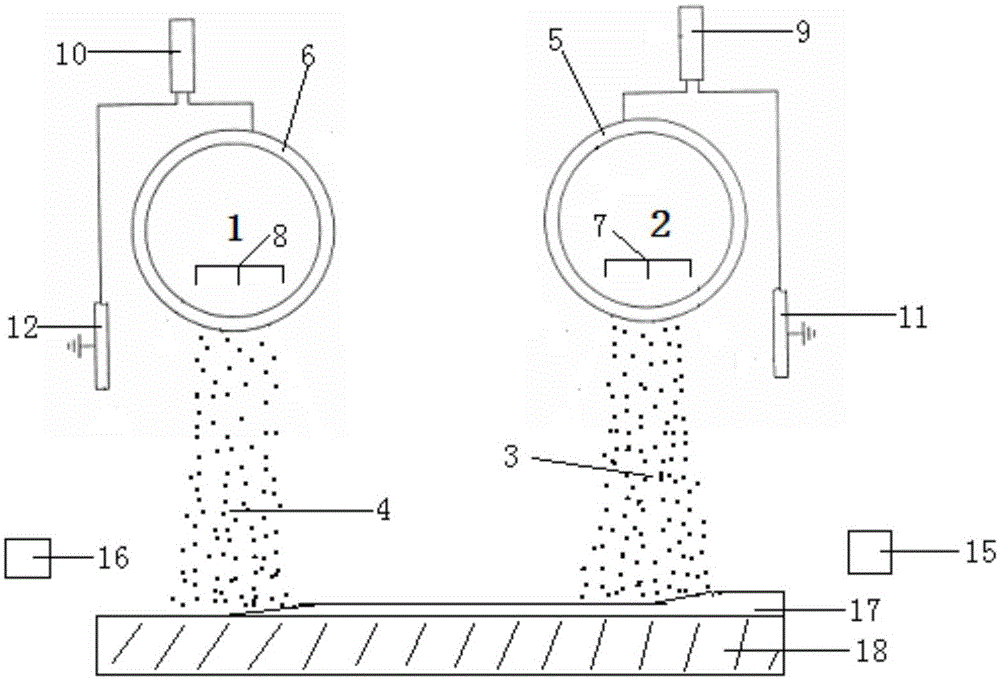

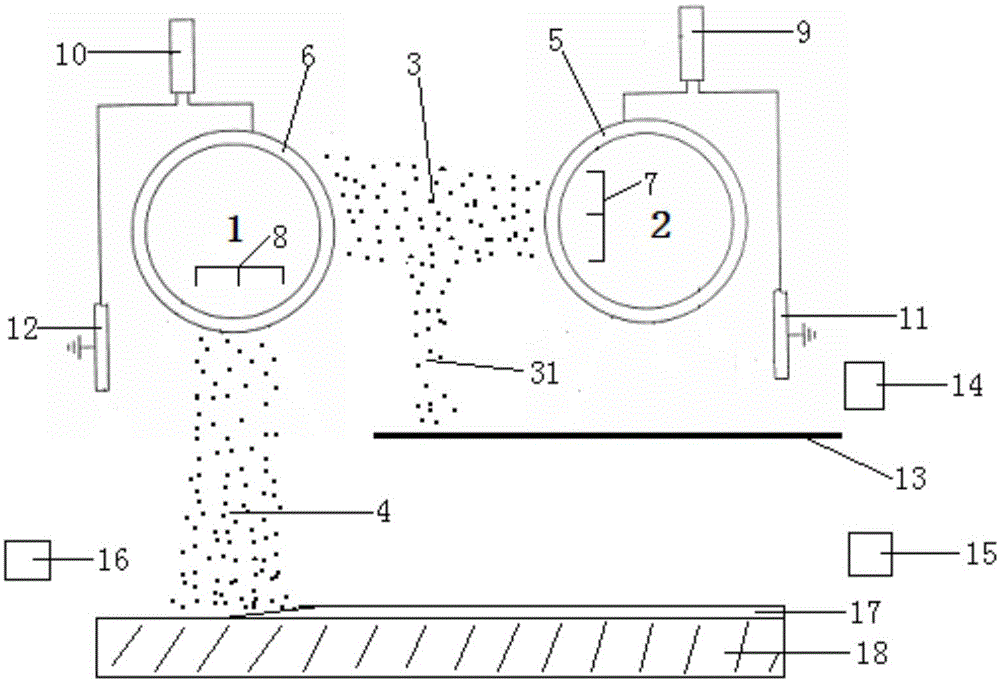

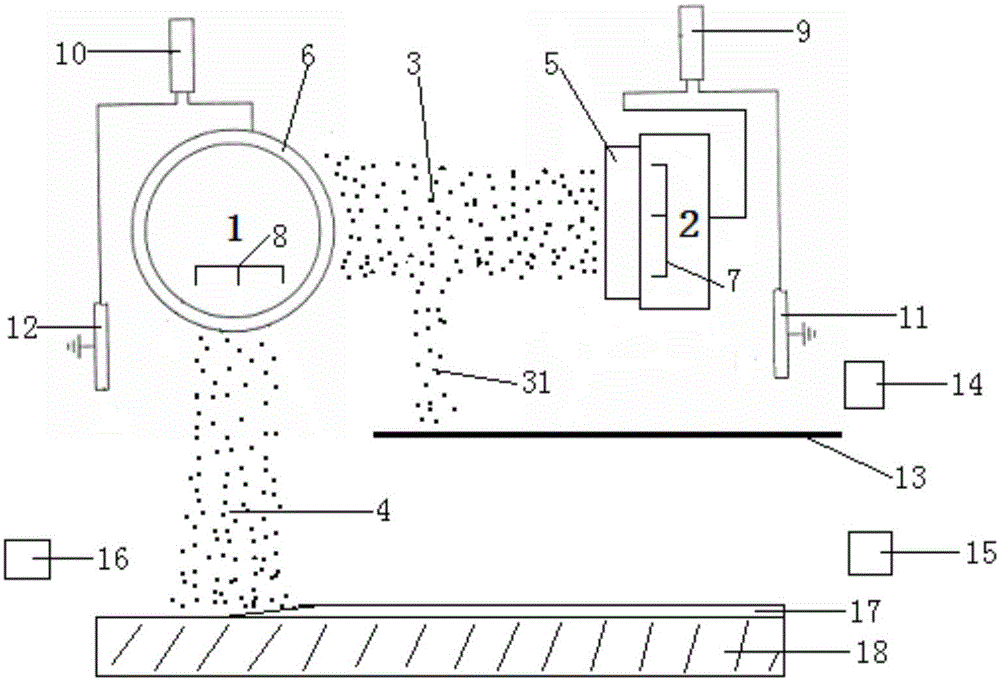

[0034] The internal structure of the vacuum chamber of the preparation device of the thin film solar cell of the present invention is as figure 2As shown, the No. 1 target 1 includes the No. 1 target material 6 and the No. 1 target magnet 8 , and the No. 2 target 2 includes the No. 2 target material 5 and the No. 2 target magnet 7 . The No. 1 target 1 and the No. 2 target 2 are both rotating cylindrical targets, wherein the No. 2 target plasma 3 faces the surface of the No. 1 target 1, and the No. 1 target plasma 4 faces the surface of the substrate 18; the No. 1 target power supply 10 and No. 2 target power supply 9 preferably uses DC power supply or AC power supply. No. 1 target 1 and No. 2 target 2 can be connected to a power supply respectively, or they can share the same power supply; wherein No. It is conductive or non-conductive. Preferably, the No. 1 target 6 and the No. 2 target 8 have certain conductivity, and the composition of the light-absorbing layer to be depos...

Embodiment 1

[0039] In the sputtering device, the No. 1 target is an InGaSe target, the No. 2 target is a CuSe target, and both No. 1 and No. 2 targets are rotating cylindrical targets. Turn on the heating element in the sputtering device to stabilize the temperature of the substrate At 350°C, an appropriate amount of argon gas was introduced, and the DC power supply connected to the target was turned on to pre-sputter the target. The plasma ablation area of the No. 1 target faces the direction of the substrate, and the plasma ablation area of the No. 2 target faces the The surface of No. 1 target; after the pre-sputtering, the soda-lime glass substrate deposited with the molybdenum electrode layer is transported into the sputtering device, and then the substrate is deposited on the substrate to form four kinds of copper indium gallium selenide on the substrate. The thin film layer of the element, and then send the substrate into the selenization furnace for high-temperature selenizatio...

Embodiment 2

[0041] In the sputtering device, the No. 1 target is an InGaSe target, the No. 2 target is a CuSe target, and both No. 1 and No. 2 targets are rotating cylindrical targets. Turn on the heating element in the sputtering device to stabilize the temperature of the substrate At 500°C, an appropriate amount of argon gas was introduced, and the DC power supply connected to the target was turned on to pre-sputter the target. The plasma ablation area of the No. 1 target faces the direction of the substrate, and the plasma ablation area of the No. 2 target faces the The surface of No. 1 target; after the pre-sputtering, the soda-lime glass substrate deposited with the molybdenum electrode layer is transported into the sputtering device, and then the substrate is deposited with a film layer, thereby directly forming a chalcopyrite structure on the substrate. p-type copper indium gallium diselenide light absorbing layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com