Underwater tunnel construction method suitable for ultra-shallow soil covering conditions

A technology for underwater tunnels and construction methods, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve the problems of large occupied water area, the thickness of the pipe curtain method covering soil should not be less than 4m, and the impact of navigation, etc., and achieve shallow excavation depth , Navigation and flood control and little impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

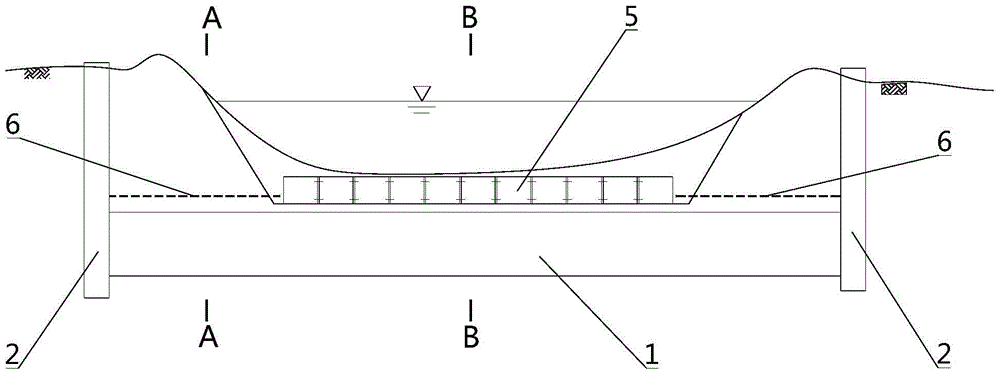

[0032] pass below Figure 1 to Figure 7 And the way of enumerating some optional embodiments of the present invention, the technical solution of the present invention (including the preferred technical solution) is described in further detail, and any technical feature and any technical solution in this embodiment do not limit the protection scope of the present invention .

[0033] Such as figure 1 As shown, the underwater tunnel construction method applicable to the ultra-shallow covering soil condition designed by the present invention comprises the following steps:

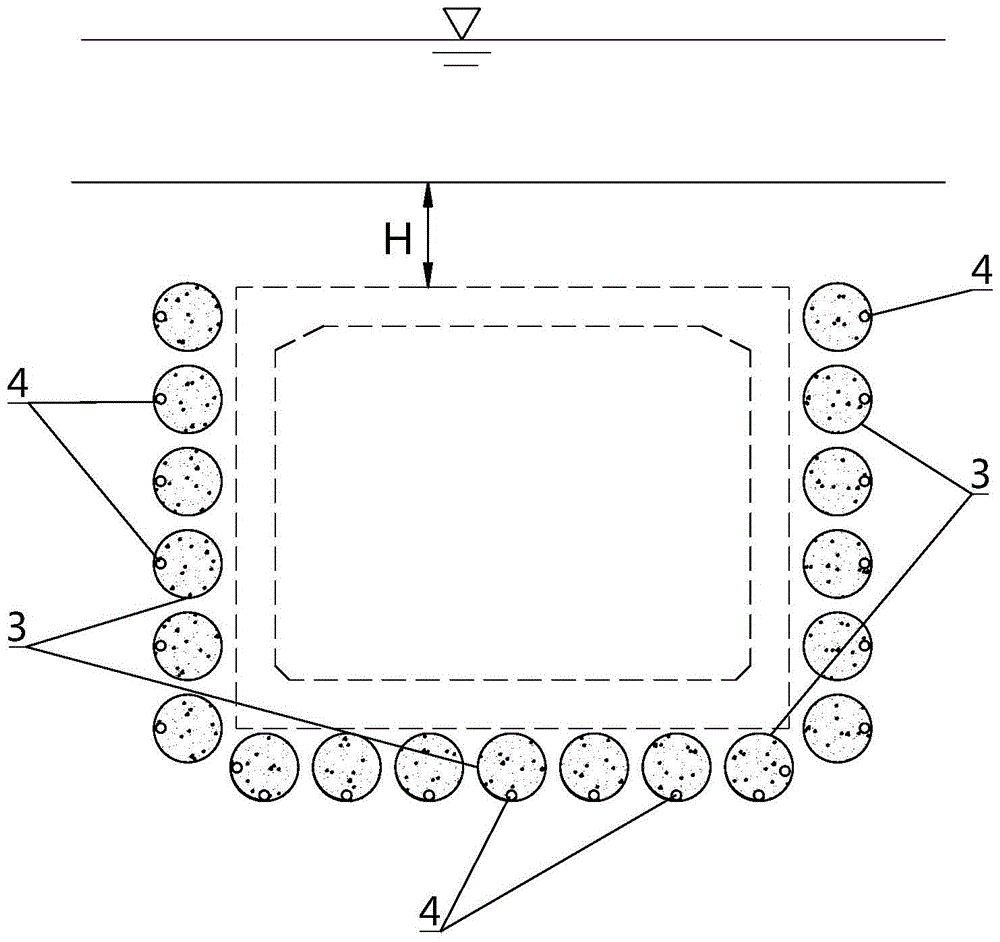

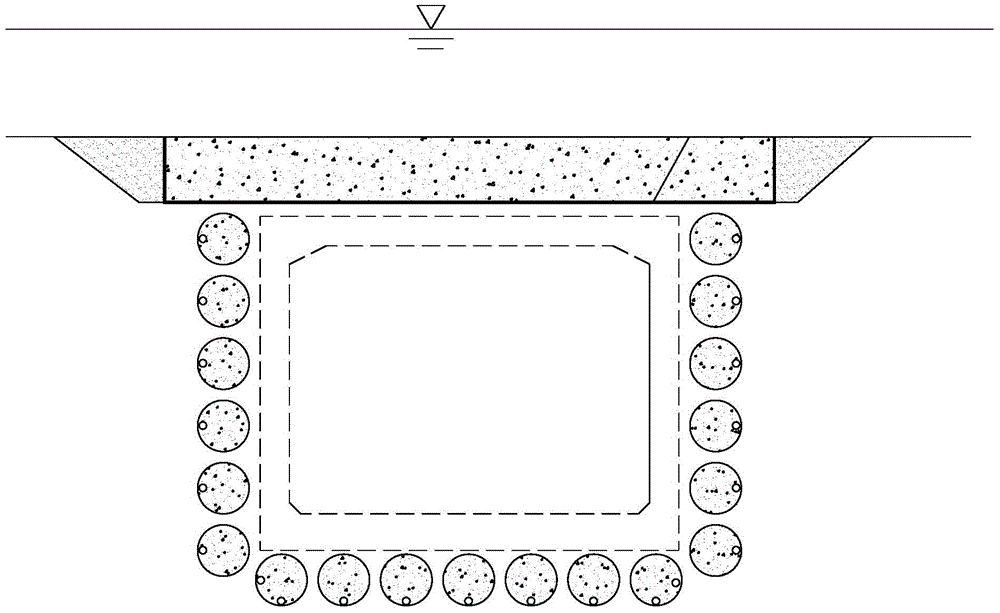

[0034] 1) Construct a working shaft 2 at the axis of the proposed tunnel 1 outside the water area; the size of the working shaft 2 must meet the space required for subsequent pipe jacking construction;

[0035] 2) In one of the working shafts 2, use a pipe jacking machine to jack a plurality of steel pipes 3 along the direction of the tunnel on the outer walls on both sides and the outer wall of the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com