A kind of coating sealing material, its preparation method and its application

A coating and sealing agent technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of reducing costs, reducing process steps, not indicating whether the surface antifouling layer has a sealing effect, whether the coating is wear-resistant, etc., to achieve excellent Corrosion resistance, long-term protection effect, excellent anti-water biosorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

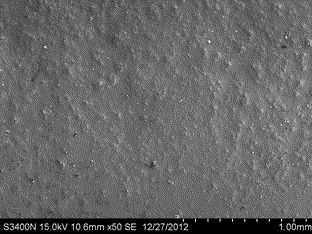

Image

Examples

Embodiment 1

[0023] One for plasma spraying Al 2 o 3 -13wt.%TiO 2 The sealing material of the ceramic coating, the composition of the sealing material mainly includes silicone resin sealing agent A, micron-sized talc powder B, mixture C, auxiliary agent and absolute ethanol solvent, and the described silicone resin sealing agent A, micron-sized The mass proportion of talcum powder B and mixture C is 100:60:120, and the additives include surface additive BYK-3700, dispersant BYK-161, defoamer BYK-066N, and leveling agent BYK-306. The auxiliary agent accounts for 6% of the total mass, the mass ratio of the silicone resin sealing agent A and the absolute ethanol solvent is 1:1.2, and the mixture C includes modified nano-scale silicon dioxide and micron-scale titanium dioxide, wherein The nanometer silicon dioxide is modified by pickling and drying, wherein the content of the modified nanometer silicon dioxide accounts for 75% of the total mass of the mixture C.

[0024] The preparation met...

Embodiment 2

[0035] One for plasma spraying Cr 2 o 3 -8wt.%TiO 2 The sealing material of the ceramic coating, the composition of the sealing material mainly includes silicone resin sealing agent A, micron-sized talc powder B, mixture C, auxiliary agent and absolute ethanol solvent, and the described silicone resin sealing agent A, micron-sized The mass ratio of talc powder B and mixture C is 100:50:100, and the additives include surface additive BYK-3700, dispersant BYK-161, defoamer BYK-066N, and leveling agent BYK-306. The auxiliary agent accounts for 7% of the total mass, the mass ratio of the silicone resin sealing agent A and the absolute ethanol solvent is 1:1.3, and the mixture C includes modified nano-scale silicon dioxide and micron-scale titanium dioxide, and the nano-scale The grade silicon dioxide is modified by pickling and drying, wherein the content of the modified nanometer grade silicon dioxide accounts for 100% of the total mass of the mixture C.

[0036] The preparati...

Embodiment 3

[0047] A kind of ZrO for plasma spraying 2 The sealing material of the ceramic coating, the composition of the sealing material mainly includes silicone resin sealing agent A, micron-sized talc powder B, mixture C, auxiliary agent and absolute ethanol solvent, and the described silicone resin sealing agent A, micron-sized The mass ratio of talc powder B and mixture C is 100:40:60, and the additives include surface additive BYK-3700, dispersant BYK-161, defoamer BYK-066N, and leveling agent BYK-306. The auxiliary agent accounts for 5% of the total mass, the mass ratio of the silicone resin sealing agent A and the absolute ethanol solvent is 1:1.1, and the mixture C includes modified nano-scale silicon dioxide and micron-scale titanium dioxide, and the nano-scale The grade silicon dioxide is modified by pickling and drying, wherein the content of the modified nanometer grade silicon dioxide accounts for 50% of the total mass of the mixture C.

[0048] The preparation method of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com