Woodware finishing paint and preparation method thereof

A technology for topcoats and woodware, which is applied in the field of woodware topcoats and its preparation, can solve the problems that woodware coatings cannot provide long-lasting antibacterial effects and no fungicides are added, so as to achieve improved sterilization effects, long-term sterilization, and effective use of resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

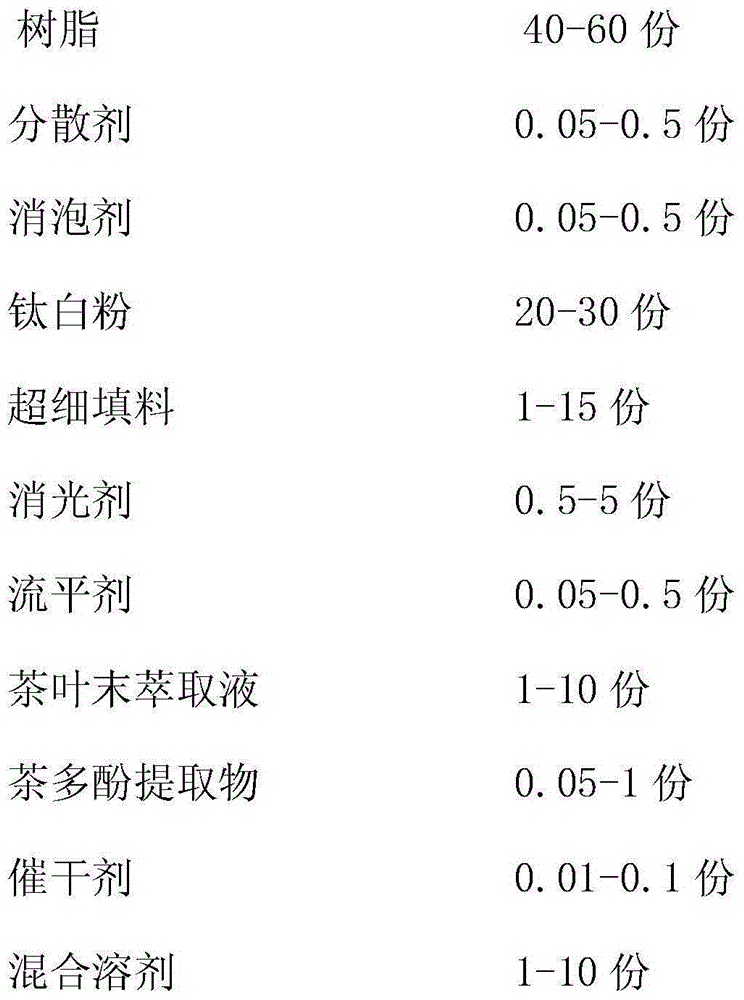

[0046] A wood finish, composed of raw materials with the following weight ratios:

[0047] A component

[0048] Coconut oil modified alkyd resin 55 parts

[0049] High molecular weight wetting and dispersing agent (such as EFKA-4010) 0.3 parts

[0050]

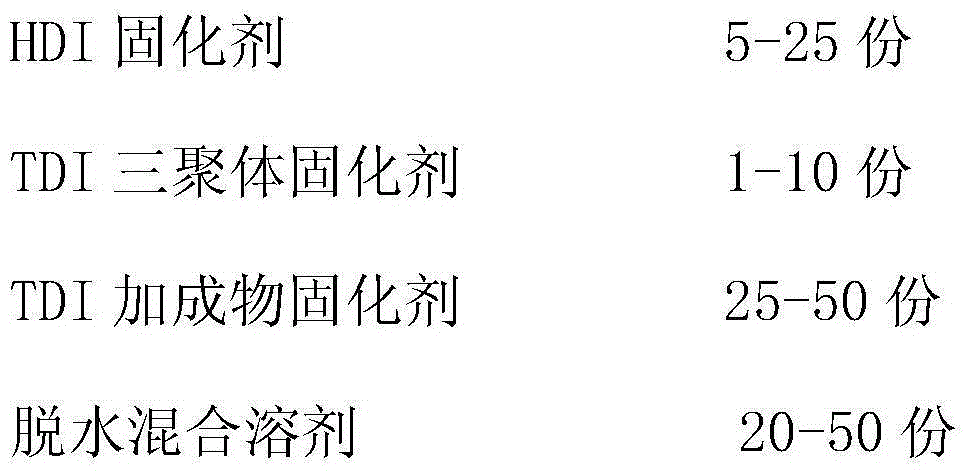

[0051] B component

[0052]

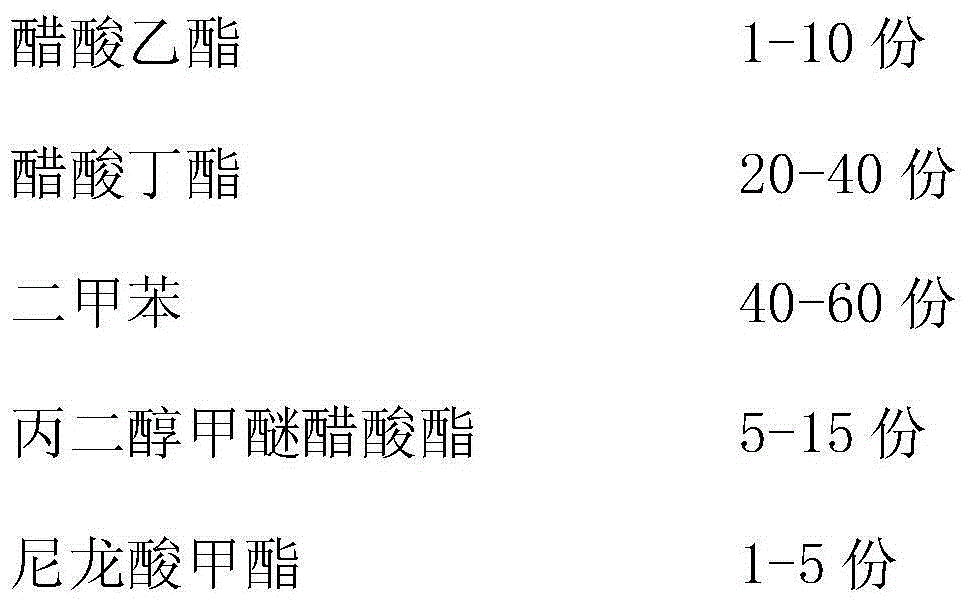

[0053] C component

[0054]

[0055] Wherein, the weight ratio of the A, B, and C components is 100:45:35.

[0056] The tea powder extract is prepared by the following preparation method:

[0057] ① Collect the drunk tea powder and dry it;

[0058] ②Put the dried tea powder and ethanol into the container at a weight ratio of 3:1;

[0059] ③After standing for 24 hours, filter the tea powder extract in the container for use;

[0060] The mixed solvent is any mixture of butyl acetate, xylene, and propylene glycol methyl ether acetate;

[0061] The dehydration mixed solvent is a mixture of dehydrated ethyl acetate and butyl acetate in a weight ratio of 1:1.

[0062] The preparation method of the wood finish includes th...

Embodiment 2

[0071] A wood finish, composed of raw materials with the following weight ratios:

[0072] A component

[0073]

[0074] B component

[0075]

[0076]

[0077] C component

[0078]

[0079] Wherein, the weight ratio of the A, B, and C components is 100:55:25.

[0080] The tea powder extract is prepared by the following preparation method:

[0081] ① Collect the drunk tea powder and dry it;

[0082] ② Put the dried tea powder and ethanol into the container at a weight ratio of 2.5:1;

[0083] ③After standing for 20 hours, filter the tea powder extract in the container for use;

[0084] The mixed solvent is any mixture of butyl acetate, xylene, and propylene glycol methyl ether acetate;

[0085] The dehydration mixed solvent is a mixture of dehydrated ethyl acetate and butyl acetate with a weight ratio of 1.2:1.

[0086] The preparation method of the wood finish includes the following steps:

[0087] ⑴ Preparation of component A:

[0088] Step 1-1: Add the resin, dispersant, and defoamer in the s...

Embodiment 3

[0095] A wood finish, composed of raw materials with the following weight ratios:

[0096] A component

[0097]

[0098] B component

[0099]

[0100]

[0101] C component

[0102]

[0103] Wherein, the weight ratio of the A, B, and C components is 100:50:45.

[0104] The tea powder extract is prepared by the following preparation method:

[0105] ① Collect the drunk tea powder and dry it;

[0106] ②Put the dried tea powder and ethanol into the container at a weight ratio of 3:1;

[0107] ③After standing for 24 hours, filter the tea powder extract in the container for use;

[0108] The resin is any mixture of coconut oil modified alkyd resin and synthetic fatty acid modified alkyd resin.

[0109] The defoamer is any mixture of a silicone defoamer and a polymer defoamer.

[0110] The leveling agent is any mixture of silicone-based leveling agents and acrylate-based leveling agents.

[0111] The mixed solvent is any mixture of butyl acetate, xylene, and propylene glycol methyl ether acetate;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com