Low-VOC low-odor environmental-friendly flame-resistant glass fiber reinforced PP composite material and preparation method thereof

A composite material and low-odor technology, which is applied in the field of polymer composite materials and its preparation, can solve problems such as health hazards and changes in polymer properties, and achieve the effects of non-flame retardant, simple preparation process, and reasonable product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

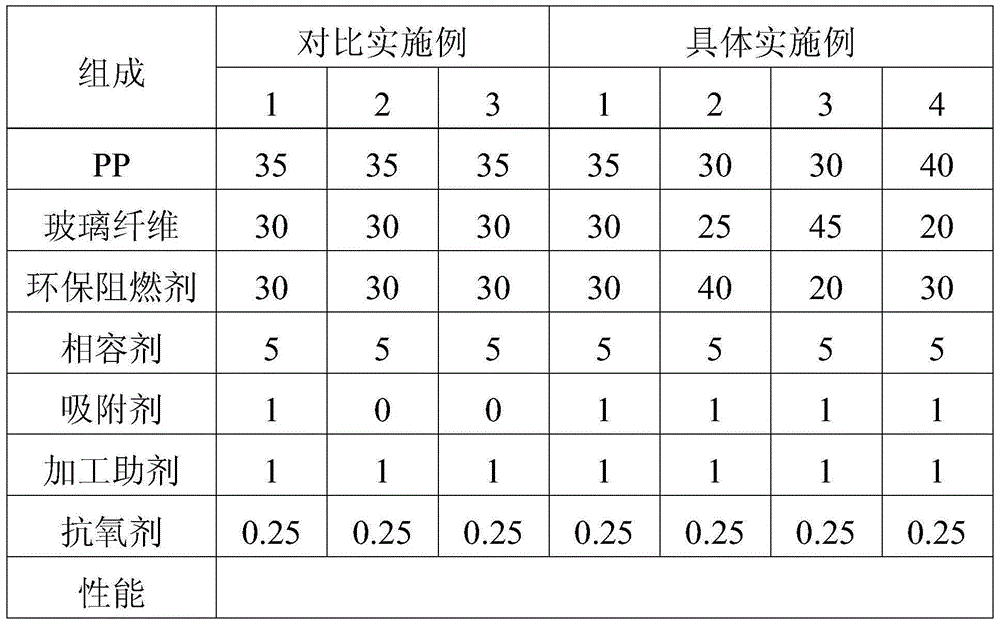

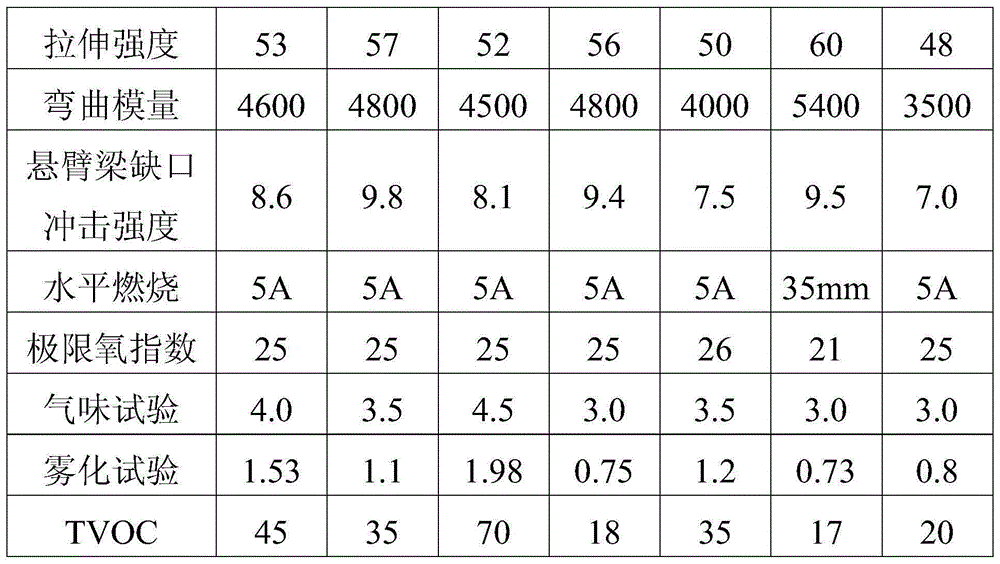

specific Embodiment 1

[0022] Take by weighing PP resin (the mass percent composition of ethylene in this PP resin is 8%, and this PP resin melt index is 30g / 10min) 35kg, environmental protection flame retardant (phosphorus content ≥ 8%; Nitrogen content ≥ 25%; Molecular weight ≥2000;) 30kg, compatibilizer (grafting rate 1.5%, melt index 100g / 10min) 5kg, adsorbent (molecular sieve (500 mesh) / zinc oxide (average particle diameter 50 nanometers) / titanium dioxide (average particle diameter 40 nanometers) )=2:1:1) 1.0kg, processing aid (calcium stearate / TAF=1:1) 1.0kg, antioxidant (antioxidant 1010 / antioxidant 168=1.5 / 1) 0.25kg, Put it into a high-mixing pot for mixing, 100r / min, 30s and then 600r / min mixing for 120s, put the resulting mixture into the hopper of the twin-screw extruder, add glass fiber (30kg) from the fiber port, and melt extrude For granulation, the processing temperature of the twin-screw extruder: 200°C, the residence time of the material in the screw is 2-3min, and the extrusion pre...

specific Embodiment 2

[0024] Take by weighing PP resin (the mass percentage composition of ethylene in this PP resin is 8%, and this PP resin melt index is 30g / 10min) 30kg, environmental protection flame retardant (phosphorus content ≥ 8%; Nitrogen content ≥ 25%; Molecular weight ≥2000;) 40kg, compatibilizer (grafting rate 1.5%, melt index 100g / 10min) 5kg, adsorbent (molecular sieve (500 mesh) / zinc oxide (average particle diameter 50 nanometers) / titanium dioxide (average particle diameter 40 nanometers) )=2:1:1) 1.0kg, processing aid (calcium stearate / TAF=1:1) 1.0kg, antioxidant (antioxidant 1010 / antioxidant 168=1.5 / 1) 0.25kg, Add it into a high-mixing pot for mixing, 100r / min, 30s and then 600r / min mixing for 120s, put the resulting mixture into the hopper of the twin-screw extruder, add glass fiber (25kg) from the fiber port, and melt extrude For granulation, the processing temperature of the twin-screw extruder: 200°C, the residence time of the material in the screw is 2-3min, and the extrusion ...

specific Embodiment 3

[0026] Take by weighing PP resin (the mass percentage composition of ethylene in this PP resin is 8%, and this PP resin melt index is 30g / 10min) 30kg, environmental protection flame retardant (phosphorus content ≥ 8%; Nitrogen content ≥ 25%; Molecular weight ≥2000;) 20kg, compatibilizer (grafting rate: 1.5%, melt index: 100g / 10min) 5kg, adsorbent (molecular sieve (500 mesh) / zinc oxide (average particle size 50 nanometers) / titanium dioxide (average particle size 40 nanometers)=2:1:1) 1.0kg, processing aid (calcium stearate / TAF=1:1) 1.0kg, processing aid (calcium stearate / TAF=1:1) 1.0kg, anti Oxygen agent (antioxidant 1010 / antioxidant 168=1.5 / 1) 0.25kg, put into the high mixing pot for mixing, 100r / min, 30s and then 600r / min mixing for 120s, put the resulting mixture into twin-screw extrusion In the feeding hopper of the machine, glass fiber (45kg) is added from the fiber feeding port, and is melted and extruded to granulate. The processing temperature of the twin-screw extruder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com