Method for preparation of dam cement by using coal mine wastes

A waste and dam technology, which is applied in the field of dam cement preparation, can solve problems such as waste of resources, and achieve the effects of energy saving, high utilization rate, and large consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh the raw materials according to the weight ratio of coal gangue, lime and gypsum in the ratio of 35:58.43:6.53, add 0.1-0.3% dicalcium silicate as a crystal form stabilizer, then add 3% boric acid, and grind to a fineness of 0.08nm, add 20-30% water to form, burn to 1380°C in silicon-molybdenum furnace, keep warm for 40min, cool rapidly in the air to get dam cement clinker, then mix and grind with 5% gypsum coagulant Instantly.

Embodiment 2

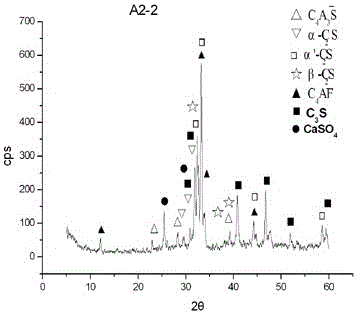

[0028] Weigh the raw materials according to the weight ratio of coal gangue, lime and gypsum as 35:57.46:7.53, add 0.1-0.3% dicalcium silicate as a crystal form stabilizer, and then add 3% boric acid, grind to make the fineness 0.08nm, add 20-30% water to form, burn to 1380°C in silicon-molybdenum furnace, keep warm for 40min, cool rapidly in the air to get dam cement clinker, and then mix powder with 5% gypsum coagulant Just grind it. figure 1 is the XRD diffraction curve of the prepared clinker.

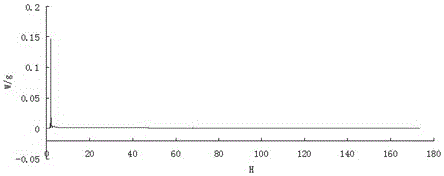

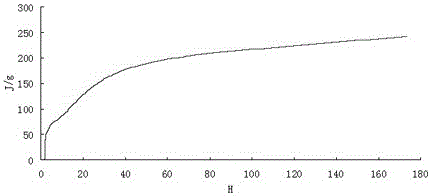

[0029] The specific test data are as follows:

[0030] The chemical composition of the clinker is shown in Table 1 (the number A2-1 is Example 1, and the number A2-2 is Example 2, the same below)

[0031] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com